Abstract

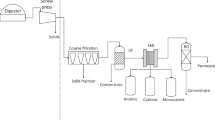

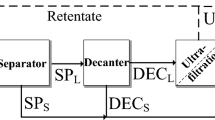

Pig slurry contains sufficient amount of nitrogen, phosphorus, and potassium for plant growth. If appropriately administered, this could substitute significant amounts of fertilizer. However, excessive fertilization with slurry causes environmental problems. To reduce environmental issues, solid-liquid separation or anaerobic digestion is needed to obtain a better distribution of nutrients. Solid-liquid separation produces a solid fraction rich in phosphorus and a liquid fraction containing ammonia, potassium, and high water content. Therefore, further concentration of ammonia is desired for any practical use. In this study, ammonia membrane stripping was carried out using polypropylene membranes and the impact of temperature, flow velocities, and liquid fraction pretreatment on the membrane contactor performance was tested. Sieved liquid effluents from a decanter centrifuge, a screw press, an AL-2 system (flocculation and filtration), and an anaerobic digester were tested. Since the properties of these liquid effluents vary, they might affect ammonia recovery. Thus, it is essential to investigate which effluent is most suitable as a feed for a membrane contactor and what is the cost of preprocessing. The mean ammonia mass transfer coefficient at 30 °C was found to be equal to 17 ± 2 × 10−3 m h−1. At 50 °C, it was found to be equal to 29 ± 2 × 10−3 m h−1 for all the tested effluents. This means that sieving after slurry separation or anaerobic digestion alleviates the influence the solid-liquid separation has on ammonia membrane stripping. However, the cost evaluation showed that solid-liquid separation using a decanter centrifuge followed by sieve draining is the cheapest of the methods investigated.

Similar content being viewed by others

Abbreviations

- A filter :

-

filter area (m2)

- A m :

-

membrane area (m2)

- A sieve :

-

laboratory sieve filter area (m2)

- AL-2 system:

-

commercial flocculation and filtration system for solid-liquid slurry separation (AL-2 Teknik A/S, Hovborg, Denmark).

- C f :

-

concentration of solids in the feed effluent (kg m−3)

- C TAN(t):

-

TAN concentration at time t (g L−1)

- C TAN0 :

-

TAN concentration at time zero (Initial effluent feed concentration in a membrane stripping experiment) (g L−1)

- DM:

-

dry matter

- Ei:

-

collected liquid slurry effluents. i: 1–5 refers to different farms and pretreatments as shown in Fig. 1

- Ei*:

-

collected liquid slurry effluents sieved through a 125-μm aperture sieve. i: 1–5 refers to different farms and pretreatments as shown in Fig. 1

- Ei**:

-

collected liquid slurry effluents sieved through a 125-μm aperture sieve. i: 1–5 refers to different farms and pretreatments as shown in Fig. 1

- g :

-

gravitational acceleration constant (m s−2)

- h t.(t):

-

actual suspension level at time t (m)

- K m :

-

overall mass transfer coefficient (m s−1)

- L :

-

length of active filter area on belt filter (m)

- M :

-

total sample mass in sieving experiment (kg)

- PP:

-

polypropylene

- R m :

-

filter medium resistance (m−1)

- SDS-PAGE:

-

sodium dodecyl sulfate-polyacrylamide gel electrophoresis

- t :

-

time (s)

- t 1 :

-

time at which sieving experiment starts (s)

- TAN:

-

total ammoniacal nitrogen

- TKN:

-

total Kjeldahl nitrogen

- TS:

-

total solids

- V f :

-

initial sample volume of feed for the membrane stripping experiment (m3)

- VS:

-

volatile solids

- V filtrate/t:

-

rate of filtrate production (m3 s−1)

- α :

-

specific cake resistance (m kg−1)

- Δp:

-

hydrostatic pressure difference across filter (Pa)

- η :

-

filtrate viscosity (Pa s)

- ρ :

-

filtrate density (kg m−3)

- χ :

-

experimental constant defined as χ = (ρ × g) / (η × α × (M / A sieve))

References

Ahn, Y. T., Hwang, Y. H., & Shin, H. S. (2011). Application of PTFE membrane for ammonia removal in a membrane contactor. Water Science and Technology, 63, 2944–2948.

Batstone, D. J., Keller, J., Angelidaki, I., Kalyuzhnyi, S. V., Pavlostathis, S. G., Rozzi, A., Sanders, W. T. M., Siegrist, H., & Vavilin, V. A. (2002). The IWA anaerobic digestion model no 1 (ADM1). Water Science and Technology, 45, 65–73.

Bouwman, A. F., Beusen, A. H. W., & Billen, G. (2009). Human alteration of the global nitrogen and phosphorus soil balances for the period 1970–2050. Global Biogeochemical Cycles, 23(4). doi:10.1029/2009GB003576.

Burton, C. H., & Turner, C. (2003). Manure management. Treatment strategies for sustainable agriculture (2nd ed.). Bedford: Silsoe Research Institute.

Christensen, M. L., Dominiak, D. M., Nielsen, P. H., Keiding, K., & Sedin, M. (2010). Gravitational drainage of compressible organic materials. AICHE Journal, 56, 3099–3108.

Christensen, M. L., Hjorth, M., & Keiding, K. (2009). Characterization of pig slurry with reference to flocculation and separation. Water Research, 43, 773–783.

DB, H.D. (2013). HUBER Drainbelt DB. http://www.huber.fi/res/Pdf/db_en.pdf. Accessed 10 Aug 2015.

De Vries, J. W., Groenestein, C. M., & De Boer, I. J. M. (2012). Environmental consequences of processing manure to produce mineral fertilizer and bio-energy. Journal of Environmental Management, 102, 173–183.

du Preez, J., Norddahl, B., & Christensen, K. (2005). The BIOREK(R) concept: a hybrid membrane bioreactor concept for very strong wastewater. Desalination, 183, 407–415.

Foged, H. (2011). Conversion to manure concentrates, Kumac Mineralen—description of a case for handling livestock manure with innovative technology in the Netherlands. Tjele: Agro Business Park A/S http://agro-technology-las.eu/docs/repo20905_conversion_to_manure_concentrates.pdf. Accessed 1 July 2015.

Halberg, N., Kristensen, E. S., & Kristensen, I. S. (1995). Nitrogen turnover on organic and conventional mixed farms. Journal of Agricultural and Environmental Ethics, 8, 30–51.

Hjorth, M., Christensen, K. V., Christensen, M. L., & Sommer, S. G. (2010). Solid-liquid separation of animal slurry in theory and practice. A review. Agronomy for Sustainable Development, 30, 153–180.

Karr, P. R., & Keinath, T. M. (1978). Influence of particle size on sludge dewaterability. Journal (Water Pollution Control Federation), 50, 1911–1930.

Laemmli, U. K. (1970). Cleavage of structural proteins during the assembly of the head of bacteriophage T4. Nature, 227, 680–685.

Masse, L., Masse, D. I., Beaudette, V., & Muir, M. (2005). Size distribution and composition of particles in raw and anaerobically digested swine manure. Transactions of the Asae, 48, 1943–1949.

McCabe, W. L., Smith, J. C., & Harriott, P. (2001). Unit operations of chemical engineering (6th ed.). Singapore: McGraw-Hill.

Moller, H. B., Sommer, S. G., & Ahring, B. K. (2002). Separation efficiency and particle size distribution in relation to manure type and storage conditions. Bioresource Technology, 85, 189–196.

Nielsen, A. H., & Kristensen, I. S. (2005). Nitrogen and phosphorus surpluses on Danish dairy and pig farms in relation to farm characteristics. Livestock Production Science, 96, 97–107.

Peters, M. S., Timmerhaus, K. D., & West, R. E. (2004). Plant design and economics for chemical engineers (5th ed.). Tokyo: Mc Graw Hill.

Semmens, M. J., Foster, D. M., & Cussler, E. L. (1990). Ammonia removal from water using microporous hollow fibers. Journal of Membrane Science, 51, 127–140.

Sørensen, P., & Thomsen, I. K. (2005). Separation of pig slurry and plant utilization and loss of nitrogen-15-labeled slurry nitrogen. Soil Science Society of America Journal, 69, 1644–1651.

Waeger-Baumann, F., & Fuchs, W. (2012). The application of membrane contactors for the removal of ammonium from anaerobic digester effluent. Separation Science and Technology (Philadelphia), 47, 1436–1442.

Wang, Z., Wu, Z., & Tang, S. (2009). Extracellular polymeric substances (EPS) properties and their effects on membrane fouling in a submerged membrane bioreactor. Water Research, 43, 2504–2512.

Werner, B. (2013). Leiblein GmbH. http://www.leiblein.com/images/stories/pdf/vacuum-belt-filter.pdf. Accessed 10 Aug 2015.

Westerman, P. W., & Bicudo, J. R. (2005). Management considerations for organic waste use in agriculture. Bioresource Technology, 96, 215–221.

Zarebska, A., Nieto, D. R., Christensen, K. V., & Norddahl, B. (2014). Ammonia recovery from agricultural wastes by membrane distillation: fouling characterization and mechanism. Water Research, 56, 1–10.

Zarebska, A., Amor, Á. C., Ciurkot, K., Karring, H., Thygesen, O., Andersen, T. P., Hägg, M.-B., Christensen, K. V., & Norddahl, B. (2015). Fouling mitigation in membrane distillation processes during ammonia stripping from pig manure. Journal of Membrane Science, 484, 119–132.

Acknowledgements

The authors want to thank The Danish Agency for Science, Technology and Innovation for economical support. Further, we are grateful to M. Rishøj from GEA Westfalia for providing decanter centrifuge effluent (E2) and S. Skov for providing screw press effluent (E3). The authors’ thank E. Poorasgari and A. Farsi for help with gravitational draining tests and moreover H. Vestergaard Hemmingsen for the technical assistance in physical and chemical analyses of manure properties. Further, the authors want to thank The Danish Agency for Science, Technology and Innovation for economical support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zarebska, A., Karring, H., Christensen, M.L. et al. Ammonia Recovery from Pig Slurry Using a Membrane Contactor—Influence of Slurry Pretreatment. Water Air Soil Pollut 228, 150 (2017). https://doi.org/10.1007/s11270-017-3332-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11270-017-3332-6