Abstract

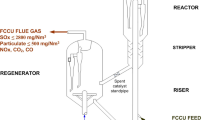

Fluid catalytic cracking unit is of great importance in petroleum refining industries as it treats heavy fractions from various process units to produce light ends (valuable products). FCC unit feedstock consists of heavy hydrocarbon with high sulfur contents, and the catalyst in use is zeolite impregnated with rare earth metals, i.e., lanthanum and cerium. Catalytic cracking reaction takes place at elevated temperature in fluidized bed reactor generating sulfur-contaminated coke on the catalyst with large quantity of attrited catalyst fines. In the regenerator, coke is completely burnt producing SO2, PM emissions. The impact of the FCC unit is assessed in the immediate neighborhood of the refinery. Year-long emission inventories for both SO2 and PM have been prepared for one of the major petroleum refining industry in Kuwait. The corresponding comprehensive meteorological data are obtained and preprocessed using Aermet (Aermod preprocessor). US EPA approved dispersion model, Aermod, is used to predict ground level concentrations of both pollutants in the selected study area. Model output is validated with measured values at discrete receptors, and an extensive parametric study has been conducted using three scenarios, stack diameter, stack height, and emission rate. It is noticed that stack diameter has no effect on ground level concentration, as stack exit velocity is a function of stack diameter. With the increase in stack height, the predicted concentrations decrease showing an inverse relation. The influence of the emission rate is linearly related to the computed ground level concentrations.

Similar content being viewed by others

References

Abdul Wahab, S. A., Al-Alawi, S. M., & El-Zawahri, A. (2002). Patterns of SO2 emissions: A refinery case study. Environmental Modeling and Software, 17, 563–570.

Alrashidi, M. S., Nassehi, V., & Wakeman, R. J. (2005). Investigation of the efficiency of the existing air pollution monitoring sites in the state of Kuwait. Environmental Pollution, 138, 219–229.

Caputo, M., Gimenez, M., & Schlamp, M. (2003). Inter-comparison of atmospheric dispersion models. Atmospheric Environment, 37, 2435–2449.

Google Inc. (2010). Google earth. Version 5.1, http://www.earth.google.com.

Isakov, V., Venkatram, A., Touma, S. J., Koracin, D., & Otte, L. T. (2007). Evaluating the use of outputs from comprehensive meteorological models in air quality modeling applications. Atmospheric Environment, 41, 1689–1705.

Kesarkar, A. P., Dalvi, M., Kaginalkar, A., & Ojha, A. (2007). Coupling of the weather research and forecasting model with AERMOD for pollutant dispersion modeling. A case study for PM10 dispersion over Pune, India. Atmospheric Environment, 41, 1976–1988.

Kulkarni, P., Chellam, S., & Fraser, M. P. (2009). Tracking petroleum refinery emission events using lanthanum and lanthanides as elemental markers for PM2.5. Environmental Science & Technology, 43(8), 2990–2991.

Lopez, J. L., & Mandujano, C. (2005). Estimation of the impact in the air quality by the use of clean fuels (fuel oil versus natural gas). Catalysis Today, 106, 176–179.

Rama Krishna, T. V. B. P. S., Reddy, M. K., Reddy, R. C., & Singh, R. N. (2004). Assimilative capacity and dispersion of pollutants due to industrial sources in Visakhapatnam bowl area. Atmospheric Environment, 38, 6775–6787.

Venkatram, A., Isakov, V., Yuana, J., & Pankratza, D. (2004). Modeling dispersion at distances of meters from urban sources. Atmospheric Environment, 38, 4633–4641.

Whitcombe, J. M., Agranovski, I. E., & Braddock, R. D. (2003). Attrition due to mixing of hot and cold FCC catalyst particles. Powder Technology, 137, 120–130.

Yateem, W., Nassehi, V., & Khan, A. R. (2010). Inventories of SO2 and PM emissions from fluid catalytic cracking (FCC) units in petroleum refineries. Water, Air, and Soil Pollution. doi:10.1007/s11270-010-0423-z.

Zou, B., Zhan, F. B., Wilson, J. G., & Zeng, Y. (2010). Performance of aermod at different time scales. Simulation Modeling Practices and Theory, 18, 612–623.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yateem, W.H., Nassehi, V. & Khan, A.R. Fluid Catalytic Cracking Unit Emissions and Their Impact. Water Air Soil Pollut 218, 37–47 (2011). https://doi.org/10.1007/s11270-010-0622-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11270-010-0622-7