Abstract

The tribological property and corrosion of a steel ball sliding against anodic oxide film (AOF) on Al-Li alloy lubricated by an ionic liquid (imidazolium hexafluorophosphate, LP108) are investigated without and with electric field. Upon sliding, no bubbles are observed without electric field (0 V) and with electric field at 1 V, while bubbles are produced continually with electric field at applied voltages of 5 V and 10 V. Higher voltage produces more bubbles. It is found that bubbles accelerate the worn-out of the AOF in sliding and corrosion of the steel ball after sliding. In the absence of bubbles, friction coefficient lower than 0.1 and long wear lifetime suggest that LP108 is a good lubricant at both 0 V and 1 V. In the presence of bubbles, however, AOF is rapidly worn out, i.e., 3.3±0.2 min at 5 V and 1.6±0.3 min at 10 V. Because the bubbles are produced continually at 5 V and 10 V, there is a rapid transition of the lubricating regime from a flooded state (boundary lubrication regime) to a bubble-dominated state (dry sliding regime). By turning off the electric field after one-minute sliding (no more newly born bubbles), the effective lubrication by LP108 can be preserved. Once the tribo-test is ended, the collapse of the bubbles occurs rapidly and hence the corrosion of the steel ball is greatly accelerated when compared to that in the absence of bubbles. In addition to bubble collapse, the bubbles are responsible for the accelerated corrosion of the steel ball because they are the reactive species of electrochemical decomposition of LP108 by synergistic action of electric field and friction, which is supported by experimental evidence. In other words, neither sliding friction without electric field nor electric field without sliding friction up to 10 V produces bubbles. A friction-activated mechanism is proposed to explain the synergistic action of electric field and friction. In short, sliding friction produces wear of the steel ball and this initiates friction activation of the worn surface of the steel ball. Consequently, the generation of bubbles occurs.

Similar content being viewed by others

Data Availability

Data supporting the findings of this work are available upon request.

References

Ye, C., Liu, W., Chen, Y., et al.: Room-temperature ionic liquids: a novel versatile lubricant. Chem. Comm. 21, 2244 (2001)

Zhou, F., Liang, Y., Liu, W.: Ionic liquid lubricants: designed chemistry for engineering applications. Chem. Soc. Rev. 38, 2590–2599 (2009)

Cai, M., Yu, Q., Liu, W., Zhou, F.: Ionic liquid lubricants: when chemistry meets tribology. Chem. Soc. Rev. 49, 7753 (2020)

Xie, G., Luo, J., Guo, D., et al.: Nanoconfined ionic liquids under electric fields. Appl. Phys. Lett. 96, 043112 (2010)

Somers, A.E., Howlett, P.C., MacFarlane, D.R., Forsyth, M.: A review of ionic liquid lubricants. Lubricants. 1, 3–21 (2013)

Mendonca, A.C., Padua, A.A., Malfreyt, P.: Nonequilibrium molecular simulations of new ionic lubricants at metallic surfaces: prediction of the friction. J. Chem. Theory Comput. 9(3), 1600–1610 (2013)

Elbourne, A., Sweeney, J., Webber, G.B., et al.: Adsorbed and near-surface structure of ionic liquids determines nanoscale friction. Chem. Comm. 49, 6797–6799 (2013)

Wen, X., Yuwen, F., Ding, Z., et al.: Electric arc-induced damage on electroless Ag film using ionic liquid as a lubricant under sliding electrical contact. Tribol. Int. 135, 269–276 (2019)

Cao, Z., Xia, Y., Liu, L., et al.: Study on the conductive and tribological properties of copper sliding electrical contacts lubricated by ionic liquids. Tribol. Int. 130, 27–35 (2019)

Ding, Z., Wen, X., Qu, R., Fu, Y., Yao, R., Lu, J.: Robust lubricious and low corrosive imidazolium hexafluorophosphate lubricant on multi-arc ion plating Ag-Cu/Ti film under sliding electrical contact. Tribol. Int. 151, 106451 (2020)

Yang, X., Meng, Y., Tian, Y.: Effect of imidazolium ionic liquid additives on lubrication performance of propylene carbonate under different electrical potentials. Tribol. Lett. 56, 161–169 (2014)

Hang, W., Kong, L., Wang, X.: Electrical sliding friction lubricated with ionic liquids. Tribol. Lett. 65, 17 (2016)

Yuwen, F., Qiao, Y., Ding, Z., Wang, B., et al.: Electroless Ag films for ionic liquid lubricated electrical contact. Thin Solid Films 733, 138818 (2021)

Gan, S., Wu, M., Sun, S., et al.: Electro-decomposition mechanism of ionic liquids 1-butyl-3-methylimidazolium tetrafluoroborate. Chin. J. Anal. Chem. in Chinese, online

Li, X., Johnson, K.E.: Electrochemistry of 1-butyl-3-methyl-1H-imidazolium tetrafluoroborate ionic liquid. J. Electrochem. Soc. 150, E307–E311 (2003)

Bortolami, M., Magboo, F.J.P., Petrucci, R., et al.: Electrogenerated BF3 from tetrafluoroborate-based ionic liquids: theoretical and experimental studies towards selective styrene oxide isomerization. J. Electrochem. Soc. 168, 115501 (2021)

Tian, Y., Goff, G.S., Runde, W.H., Batista, E.R.: Exploring electrochemical windows of room-temperature ionic liquids: a computational study. J. Phys. Chem. B. 116, 11943–11952 (2012)

Merouani, S., Hamdaoui, O., Haddad, B.: Acoustic cavitation in 1-butyl-3-methylimidazolium bis(triflluoromethylsulfonyl)imide based ionic liquid. Ultrason. Sonochem. 41, 143–155 (2018)

Kanthale, P.M., Ashokkumar, M., Grieser, F.: Estimation of cavitation bubble temperatures in an ionic liquid. J. Phys. Chem. C 111, 18461–18463 (2007)

Oxley, J.D., Prozorov, T., Suslick, K.S.: Sonochemistry and sonoluminescence of room-temperature ionic liquids. J. Am. Chem. Soc. 125, 11138–11139 (2003)

Kong, L., Hang, W., Wang, X.: Ionic liquid lubrication at electrified interfaces. J. Phys. D Appl. Phys. 49, 225301 (2016)

Lu, J., Zum Gahr, K.H., Schneider, J.: Microstructural effects on the resistance to cavitation erosion of ZrO2 ceramics in water. Wear 265, 1680–1686 (2008)

Ma, Y., Li, K., Zhou, X., et al.: Effect of barrier layer on corrosion resistance of porous-type anodic films formed on AA2055 Al-Cu-Li alloy and pure aluminum. J. Electrochem. Soc. 167, 041508 (2020)

Karakashev, S.I., Stöckelhuber, K.W., Tsekov, R., et al.: Tribology of thin wetting films between bubble and moving solid surface. Adv. Coll. Interface. Sci. 210, 39–46 (2014)

Goodwin, M.J., Dong, D., Yu, H., et al.: Theoretical and experimental investigation of the effect of oil aeration on the load-carrying capacity of a hydrodynamic journal bearing. Proc. Inst. Mech. Eng. Part J: J. Eng. Tribol. 221, 779–786 (2007)

Acknowledgements

This work is supported by the Natural Science Foundation of China (51775434), Hundred Talent of Shaanxi Province, and opening project of State Key Laboratory of Solid Lubrication (LSL16-02).

Author information

Authors and Affiliations

Contributions

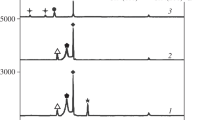

JC and RQ wrote the main manuscript text and prepared Figures 4–11 and LC prepared Figures 1–3. RY and JL wrote the abstract and conclusions. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Cao, J., Qu, R., Chen, L. et al. Tribological Property and Corrosion of Imidazolium-Based Ionic Liquid-Lubricated Steel Sliding Against Anodic Oxide Film on Al-Li Alloy in the Presence of Bubbles Produced by Synergistic Action of Electric Field and Friction. Tribol Lett 72, 49 (2024). https://doi.org/10.1007/s11249-024-01852-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-024-01852-6