Abstract

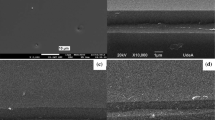

The primary objective of this research is to investigate the mechanical and tribological characteristics of thin coatings that consist of graphite-like carbon (GLC) and chromium nitride (CrN). The incorporation of GLC and CrN coatings offers a synergistic effect by leveraging the wear-resistant properties of CrN and the low-friction and lubricating properties of GLC. Unbalanced closed-field magnetron sputtering was employed to deposit CrN/GLC coatings onto SDC90 steel. The microstructure, mechanical, and tribological properties of the coatings were comprehensively studied and compared. From the Raman, the ID/IG of the GLC coatings improved from 1.7 to 2.7 by changing the GLC coating thicknesses from 0.2 to 2.0 μm. The records displayed that changing the GLC coating thickness of the CrN/GLC coating can reduce the surface toughness, adhesion strength, and critical loads (the critical loads of S1 and S2 > 40 N, the critical load of S3 < 30–40 N). On the contrary, by changing the GLC coating thickness, the elasticity modulus (from 144.88 to 169.60 GPa), hardness (from 10.27 to 14.32 GPa), and tribological properties of the coatings were positively affected. Regarding the impact friction and wear behavior, the thicker GLC coatings show excellent properties with a lower wear volume and wear rate. The knowledge acquired about the GLC coatings can be utilized to enhance the impact friction and wear of the cold work die steels.

Graphical Abstract

Similar content being viewed by others

Data Availability

Data available on request from the authors.

References

Stavridis, N., Rigos, D., Papageorgiou, D., Chicinaş, I., Medrea, C.: Failure analysis of cutting die used for the production of car racks. Eng. Fail. Anal. 18(2), 783–788 (2011). https://doi.org/10.1016/j.engfailanal.2010.12.020

Okolovich, G.: Tool steels for cold working dies. Met. Sci. Heat Treat. 48(5), 233–239 (2006). https://doi.org/10.1007/s12541-017-0016-5

Song, R., Zhang, K., Chen, G.: Electron beam surface remelting of AISI D2 cold-worked die steel. Surf. Coat. Technol. 157(1), 1–4 (2002). https://doi.org/10.1016/S0257-8972(02)00136-6

Holmberg, K., Erdemir, A.: Influence of tribology on global energy consumption, costs and emissions. Friction 5(3), 263–284 (2017). https://doi.org/10.1007/s40544-017-0183-5

Dong, W.L., Yang, X.F., Song, F., Wu, M., Zhu, Y., Wang, Z.Y.: Anti-friction and wear resistance analysis of cemented carbide coatings. Int. J. Adv. Manuf. Technol. 122, 1–27 (2022). https://doi.org/10.1007/s00170-022-10092-8

Zhu, Z.-Y., Shi, W., Wan, Z., Yuan, J.-F., Li, X.: Effects of temperature on internal friction of graphit-iC graphite-like carbon coatings. TFPA 13, 209–214 (2013). https://doi.org/10.1117/12.2054073

He, S., Li, C., Ren, J., Han, Y.: Investigation on alloying element distribution in Cr8Mo2SiV cold-work die steel ingot during homogenization. Steel Res. Int. 89(10), 1800148 (2018). https://doi.org/10.1002/srin.201800148

Wu, H., Mao, H., Ning, H., Deng, Z., Wu, X.: Friction behavior and self-lubricating mechanism of SLD-MAGIC cold worked die steel during different wear conditions. Metals 13(4), 809 (2023). https://doi.org/10.3390/met13040809

Tkadletz, M., Schalk, N., Daniel, R., Keckes, J., Czettl, C., Mitterer, C.: Advanced characterization methods for wear resistant hard coatings: a review on recent progress. Surf. Coat. Technol. 285, 31–46 (2016). https://doi.org/10.1016/j.surfcoat.2015.11.016

Fan, Q.X., Wang, T.G., Liu, Y.M., Wu, Z.H., Zhang, T., Li, T., Yang, Z.-B.: Microstructure and corrosion resistance of the AlTiN coating deposited by arc ion plating. Acta Metall. Sin. (Engl. Lett.) 29(12), 1119–1126 (2016). https://doi.org/10.1007/s40195-016-0497

Li, H., Sun, P., Cheng, D.: Structure and properties of a-C:H:Si:O films deposited by cage-like hollow cathode discharge on AZ31 alloy. Tribol. Int. 175, 107848 (2022). https://doi.org/10.1016/j.triboint.2022.107848

Mendibide, C., Fontaine, J., Steyer, P., Esnouf, C.: Dry sliding wear model of nanometer scale multilayered TiN/CrN PVD hard coatings. Tribol. Lett. 17, 779–789 (2004)

Du, J.W., Chen, L., Chen, J., Du, Y.: Mechanical properties, thermal stability and oxidation resistance of TiN/CrN multilayer coatings. Vacuum 179, 109468 (2020). https://doi.org/10.1016/j.vacuum.2020.109468

Lomello, F., Yazdi, M.A.P., Sanchette, F., Schuster, F., Tabarant, M., Billard, A.: Temperature dependence of the residual stresses and mechanical properties in TiN/CrN nanolayered coatings processed by cathodic arc deposition. Surf. Coat. Technol. 238, 216–222 (2014). https://doi.org/10.1016/j.surfcoat.2013.10.079

Carrera, S., Salas, O., Moore, J., Woolverton, A., Sutter, E.: Performance of CrN/MoS2 (Ti) coatings for high wear low friction applications. Surf. Coat. Technol. 167(1), 25–32 (2003). https://doi.org/10.1016/S0257-8972(02)00885-X

Gorokhovsky, V.I., Bhat, D.G., Shivpuri, R., Kulkarni, K., Bhattacharya, R., Rai, A.: Characterization of large area filtered arc deposition technology: part II—coating properties and applications. Surf. Coat. Technol. 140(3), 215–224 (2001). https://doi.org/10.1016/S0257-8972(01)01023-4

Bull, S.J., Bhat, D.G., Staia, M.H.: Properties and performance of commercial TiCN coatings. Part 2: tribological performance. Surf. Coat. Technol. 163, 507–514 (2003). https://doi.org/10.1016/S0257-8972(02)00651-5

Jasempoor, F., Elmkhah, H., Imantalab, O., Fattah-Alhosseini, A.: Improving the mechanical, tribological, and electrochemical behavior of AISI 304 stainless steel by applying CrN single layer and Cr/CrN multilayer coatings. Wear 504, 204425 (2022). https://doi.org/10.1016/j.wear.2022.204425

Kazlauskas, D., Jankauskas, V., Kreivaitis, R., Tučkutė, S.: Wear behaviour of PVD coating strengthened WC-Co cutters during milling of oak-wood. Wear 498, 204336 (2022). https://doi.org/10.1016/j.wear.2022.204336

Zhang, G.G.: Friction and wear behaviors of carbon-based multilayer coatings sliding against different rubbers in water environment. Tribol. Int. (2013). https://doi.org/10.1016/j.triboint.2013.02.009

Diesselberg, M., Stock, H.-R., Mayr, P.: Friction and wear behaviour of PVD chromium nitride supported carbon coatings. Surf. Coat. Technol. 188, 612–616 (2004). https://doi.org/10.1016/j.surfcoat.2004.07.023

Wan, S., Pu, J., Li, D., Zhang, B., Tieu, A.K.: Tribological performance of CrN and CrN/GLC coated components for automotive engine applications. J. Alloys Compd. 695, 433–442 (2017). https://doi.org/10.1016/j.jallcom.2016.11.118

Wang, L., Guan, X., Zhang, G.: Friction and wear behaviors of carbon-based multilayer coatings sliding against different rubbers in water environment. Tribol. Int. 64, 69–77 (2013). https://doi.org/10.1016/j.triboint.2013.02.009

Yang, J., Zhao, K., Wang, G., Deng, C., Liu, N., Zhang, W., Yang, J.: Influence of coating thickness on microstructure, mechanical and LBE corrosion performance of amorphous AlCrFeTiNb high-entropy alloy coatings. Surf. Coat. Technol. 441, 128502 (2022). https://doi.org/10.1016/j.surfcoat.2022.128502

Kashkarov, E., Sidelev, D., Pushilina, N., Yang, J., Tang, C., Steinbrueck, M.: Influence of coating parameters on oxidation behavior of Cr-coated zirconium alloy for accident tolerant fuel claddings. Corros. Sci. 203, 110359 (2022). https://doi.org/10.1016/j.corsci.2022.110359

Marimuthu, K.P., Jeong, U., Han, J., Han, G., Lee, H.: Influence of substrate type and film thickness on the failures of Zr-based thin-film metallic glass under nanoscratch. Wear 494, 204241 (2022). https://doi.org/10.1016/j.wear.2022.204241

Sidelev, D., Ruchkin, S., Syrtanov, M., Kashkarov, E., Shelepov, I., Malgin, A., Polunin, K., Stoykov, K., Mokrushin, A.: Protective Cr coatings with CrN/Cr multilayers for zirconium fuel claddings. Surf. Coat. Technol. 433, 128131 (2022). https://doi.org/10.1016/j.surfcoat.2022.128131

Shi, X., Liskiewicz, T.W., Beake, B.D., Chen, J., Wang, C.: Tribological performance of graphite-like carbon films with varied thickness. Tribol. Int. 149, 105586 (2020). https://doi.org/10.1016/j.triboint.2019.01.045

Liu, D., Benstetter, G., Lodermeier, E.: Surface roughness, mechanical and tribological properties of ultrathin tetrahedral amorphous carbon coatings from atomic force measurements. Thin Solid Films 436(2), 244–249 (2003). https://doi.org/10.1016/S0040-6090(03)00592-3

Li, X., Xu, S., Ke, P., Wang, A.: Thickness dependence of properties and structure of ultrathin tetrahedral amorphous carbon films: a molecular dynamics simulation. Surf. Coat. Technol. 258, 938–942 (2014). https://doi.org/10.1016/j.surfcoat.2014.07.054

Wang, Y., Li, J., Lei, S., Chen, J., Xue, Q.: Tribological performances of the graphite-like carbon films deposited with different target powers in ambient air and distilled water. Tribol. Int. 73(73), 17–24 (2014). https://doi.org/10.1016/j.triboint.2013.12.022

Kinoshita, Y., Murashima, M., Kawachi, M., Ohno, N.: First-principles study of mechanical properties of one-dimensional carbon nanotube intramolecular junctions. Comput. Mater. Sci. 70, 1–7 (2013). https://doi.org/10.1016/j.commatsci.2012.12.033

Mohiuddin, T., Lombardo, A., Nair, R., Bonetti, A., Savini, G., Jalil, R., Bonini, N., Basko, D., Galiotis, C., Marzari, N.: Uniaxial strain in graphene by Raman spectroscopy: G peak splitting, Grüneisen parameters, and sample orientation. Phys. Rev. B 79(20), 205433 (2009). https://doi.org/10.1103/PhysRevB.79.205433

Chan, K.T., Neaton, J., Cohen, M.L.: First-principles study of metal adatom adsorption on graphene. Phys. Rev. B 77(23), 235430 (2008). https://doi.org/10.1103/PhysRevB.77.235430

Ferrari, A.C., Robertson, J.: Interpretation of Raman spectra of disordered and amorphous carbon. Phys. Rev. B 61(20), 14095 (2000). https://doi.org/10.1103/PhysRevB.61.14095

Yin, D., Peng, X., Yi, Q., Wang, Z.: Impact of residual stress on the adhesion and tensile fracture of TiN/CrN multi-layered coatings from first principles. Physica E (Amsterdam, Neth.) 44(9), 1838–1845 (2012). https://doi.org/10.1016/j.physe.2012.05.008

Majzoobi, G., Mahmoudi, A., Moradi, S.: Ductile to brittle failure transition of HSLA-100 Steel at high strain rates and subzero temperatures. Eng. Fract. Mech. 158, 179–193 (2016). https://doi.org/10.1016/j.engfracmech.2016.03.001

Du, X.-B., Li, D.-S., Jiang, L., Fang, D.-N.: Experimental study on the low-temperature compression performance of 3D five-directional braided composites applied to extreme environments. Mater. Lett. 324, 132767 (2022). https://doi.org/10.1016/j.matlet.2022.132767

Batory, D., Jedrzejczak, A., Kaczorowski, W., Szymanski, W., Kolodziejczyk, L., Clapa, M., Niedzielski, P.: Influence of the process parameters on the characteristics of silicon-incorporated a-C:H:SiOx coatings. Surf. Coat. Technol. 271, 112–118 (2015). https://doi.org/10.1016/j.triboint.2013.12.022

Wang, X., Sui, X., Zhang, S., Yan, M., Yang, J., Hao, J., Liu, W.: Effect of deposition pressures on uniformity, mechanical and tribological properties of thick DLC coatings inside of a long pipe prepared by PECVD method. Surf. Coat. Technol. 375, 150–157 (2019). https://doi.org/10.1002/ep.13996

Otsubo, F., Era, H., Kishitake, K., Uchida, T.: Properties of Cr3C2-NiCr cermet coating sprayed by high power plasma and high velocity oxy-fuel processes. J. Therm. Spray Technol. 9, 499–504 (2000)

Yin, Z., Tao, S., Zhou, X., Ding, C.: Evaluating microhardness of plasma sprayed Al2O3 coatings using Vickers indentation technique. J. Phys. D 40(22), 7090 (2007). https://doi.org/10.1088/0022-3727/40/22/034

Amaratunga, G., Chhowalla, M., Kiely, C., Alexandrou, I., Aharonov, R., Devenish, R.: Hard elastic carbon thin films from linking of carbon nanoparticles. Nature 383(6598), 321–323 (1996). https://doi.org/10.1038/383321a0

Li, X., Bhushan, B.: Evaluation of fracture toughness of ultra-thin amorphous carbon coatings deposited by different deposition techniques. Thin Solid Films 355, 330–336 (1999). https://doi.org/10.1016/S0040-6090(99)00446-0

Li, X., Bhushan, B.: Measurement of fracture toughness of ultra-thin amorphous carbon films. Thin Solid Films 315(1–2), 214–221 (1998). https://doi.org/10.1016/S0040-6090(97)00788-8

Oliver, W.C., Pharr, G.M.: An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7(6), 1564–1583 (1992). https://doi.org/10.1557/JMR.1992.1564

Leyland, A., Matthews, A.: On the significance of the H/E ratio in wear control: a nanocomposite coating approach to optimised tribological behaviour. Wear 246(1–2), 1–11 (2000). https://doi.org/10.1016/S0043-1648(00)00488-9

Chen, J., Li, H., Beake, B.D.: Load sensitivity in repetitive nano-impact testing of TiN and AlTiN coatings. Surf. Coat. Technol. 308, 289–297 (2016). https://doi.org/10.1016/j.surfcoat.2016.05.094

Wang, L., Zhang, R., Luan, J., Cao, D.: Effect of different deformation on the order degree of coal-based graphite. Energy Source A (2021). https://doi.org/10.1080/15567036.2021.1983084

Li, Z., Guan, X., Wang, Y., Li, J., Cheng, X., Lu, X., Wang, L., Xue, Q.: Comparative study on the load carrying capacities of DLC, GLC and CrN coatings under sliding-friction condition in different environments. Surf. Coat. Technol. 321, 350–357 (2017). https://doi.org/10.1016/j.surfcoat.2017.04.065

Jiang, H., Jiang, L., Qiao, D., Lu, Y., Wang, T., Cao, Z., Li, T.: Effect of niobium on microstructure and properties of the CoCrFeNbxNi high entropy alloys. J. Mater. Sci. Technol. 33(7), 712–717 (2017). https://doi.org/10.1016/j.jmst.2016.09.016

Zhang, D., Peng, L., Yi, P., Lai, X.: Electronic transport and corrosion mechanisms of graphite-like nanocrystalline carbon films used on metallic bipolar plates in proton-exchange membrane fuel cells. ACS Appl. Mater. Interfaces 13(3), 3825–3835 (2021). https://doi.org/10.1021/acsami.0c17764

Siegel, D.J., Hector, L.G., Adams, J.B.: Adhesion, stability, and bonding at metal/metal-carbide interfaces: Al/WC. Surf. Sci. 498(3), 321–336 (2002). https://doi.org/10.1016/S0039-6028(01)01811-8

Funding

This work was supported by the National Science Fund for Excellent Young Scholars (Oversea), China Postdoctoral Science Foundation Funded Project (Project No. 2021M693415), Jiangsu Provincial Postdoctoral Science Foundation Funded Project (Project No. 2020C340), Jiangsu Provincial Double-Innovation Doctor Program (Project No. 202031063), and China Postdoctoral International Exchange Program (Project No. PC2022061).

Author information

Authors and Affiliations

Contributions

HL contributed to formal analysis, conceptualization, and writing of the manuscript. RD contributed to investigation, formal analysis, and writing of the original draft. YS contributed to formal analysis. JY contributed to supervision, resources, and funding acquisition. MA contributed to writing, reviewing, & editing of the manuscript.

Corresponding author

Ethics declarations

Competing Interests

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lin, H., Dai, R., Shi, Y. et al. Effect of the GLC Coating Thickness on the Mechanical and Tribological Properties of the CrN/GLC Coatings. Tribol Lett 71, 92 (2023). https://doi.org/10.1007/s11249-023-01768-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-023-01768-7