Abstract

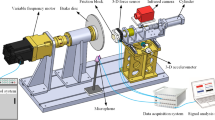

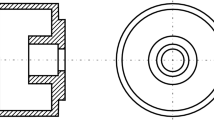

The influence of friction blocks connection configuration on the interfacial tribology behavior and FIVN (friction-induced vibration and noise) of the high-speed railway braking system is systematically investigated with a scaled brake test bench. The potential relationship among interface contact status, friction, wear, pressure distribution, thermal response, and vibration noise of the system is studied under dragging test conditions. The results indicate that the connection configuration of the friction blocks has a significant impact on systematic interfacial tribology behavior, thermal response, and vibration noise. A floating connection mode can suppress the vibration noise of the brake system. The interfacial thermal response and systematic vibration noise are quite relevant with the contact status, interfacial wear, and pressure distribution. The increase of interfacial wear will lead to an expansion of pressure concentration area and an aggravation of vibration noise. This research is helpful for further design optimization and noise reduction of the railway brake system.

Similar content being viewed by others

References

Xiao, J.K., Xiao, S.X., Chen, J., Zhang, C.: Wear mechanism of Cu-based brake pad for high-speed train braking at speed of 380 km/h. Tribol. Int. 150, 106357 (2020). https://doi.org/10.1016/j.triboint.2020.106357

Kasem, H., Brunel, J.F., Dufrenoy, P., Siroux, M., Desmet, B.: Thermal levels and subsurface damage induced by the occurrence of hot spots during high-energy braking. Wear 270, 355–364 (2013). https://doi.org/10.1016/j.wear.2010.11.007

Shin, M.W., Kim, Y.H., Jang, H.: Effect of the abrasive size on the friction effectiveness and instability of brake friction materials: a case study with zircon. Tribol. Lett. 55, 371–379 (2014). https://doi.org/10.1007/s11249-014-0361-9

Peng, T., Yan, Q., Li, G., Zhang, X., Wen, Z., Jin, X.: The braking behaviors of Cu-based metallic brake pad for high-speed train under different initial braking speed. Tribol. Lett. 65, 135 (2017). https://doi.org/10.1007/s11249-017-0914-9

Peng, T., Yan, Q., Zhang, X.: Stability of metal matrix composite pads during high-speed braking. Tribol. Lett. 66, 63 (2018). https://doi.org/10.1007/s11249-018-1014-1

Panier, S., Dufrénoy, P., Weichert, D.: An experimental investigation of hot spots in railway disc brakes. Wear 256, 764–773 (2007). https://doi.org/10.1016/S0043-1648(03)00459-9

Cristol-Bulthé, A.L., Desplanques, Y., Degallaix, G.: Coupling between friction physical mechanisms and transient thermal phenomena involved in pad-disc contact during railway braking. Wear 263, 1230–1242 (2007). https://doi.org/10.1016/j.wear.2006.12.052

Abdullah, O.I., Schlattmann, J.: Temperature analysis of a pin-on-disc tribology test using experimental and numerical approaches. Friction 4, 135–143 (2016). https://doi.org/10.1007/s40544-016-0110-1

Tang, B., Mo, J.L., Xu, J.W., Wu, Y.K., Zhu, M.H., Zhou, Z.R.: Effect of perforated structure of friction block on the wear, thermal distribution and noise characteristics of railway brake systems. Wear 426–427, 1176–1186 (2019). https://doi.org/10.1016/j.wear.2019.01.016

Ma, J., Olofsson, U., Lyu, Y., Wahlström, J., Åström, A.H., Tu, M.: A comparison of airborne particles generated from disk brake contacts: induction versus frictional heating. Tribol. Lett. 68, 38 (2020). https://doi.org/10.1007/s11249-020-1279-z

Eriksson, M., Jacobson, S.: Tribological surfaces of organic brake pads. Tribol. Int. 33, 817–827 (2000). https://doi.org/10.1016/S0301-679X(00)00127-4

Federici, M., Perricone, G., Gialanella, S., Straffelini, G.: Sliding behaviour of friction material against cermet coatings: pin-on-disc study of the running-in stage. Tribol. Lett. 66, 53 (2018). https://doi.org/10.1007/s11249-018-1004-3

Massi, F., Giannini, O., Baillet, L.: Brake squeal as dynamic instability: an experimental investigation. J. Acoust. Soc. Am. 120, 1388–1398 (2006). https://doi.org/10.1121/1.2228745

Su, L., Gao, F., Han, X., Fu, R., Zhang, E.: Tribological behavior of copper-graphite powder third body on copper-based friction materials. Tribol. Lett. 60, 30 (2015). https://doi.org/10.1007/s11249-015-0605-3

Kchaou, M., Mat Lazim, A.R., Abdul Hamid, M.K., Abu Bakar, A.R.: Experimental studies of friction-induced brake squeal: influence of environmental sand particles in the interface brake pad-disc. Tribol. Int. 110, 307–317 (2017). https://doi.org/10.1016/j.triboint.2017.02.032

Nam, J.H., Do, H.C., Kang, J.Y.: Effect of groove surface on friction noise and its mechanism. Int. J. Precis. Eng. Manuf. 18, 1165–1172 (2017). https://doi.org/10.1007/s12541-017-0136-y

Lyu, H., Walsh, S.J., Chen, G., Zhang, L., Qian, K., Wang, L.: Analysis of friction-induced vibration leading to brake squeal using a three degree-of-freedom model. Tribol. Lett. 65, 105 (2017). https://doi.org/10.1007/s11249-017-0887-8

Massi, F., Rocchi, J., Culla, A., Berthier, Y.: Coupling system dynamics and contact behaviour: modelling bearings subjected to environmental induced vibrations and “false Brinelling” degradation. Mech. Syst. Signal Process. 24, 1068–1080 (2010). https://doi.org/10.1016/j.ymssp.2009.09.004

Ding, C., Zhu, H., Sun, G., Zhou, Y., Zuo, X.: Chaotic characteristics and attractor evolution of friction noise during friction process. Friction 6, 47–61 (2018). https://doi.org/10.1007/4054-017-0161-y

Wang, D.W., Mo, J.L., Ouyang, H., Zhou, Z.R.: Improving dynamic and tribological behaviours by means of a Mn-Cu damping alloy with grooved surface features. Tribol. Lett. 66, 67 (2018). https://doi.org/10.1007/s11249-018-1019-9

Zhang, P., Zhang, L., Wei, D., Wu, P., Cao, J., Shijia, C.: The synergistic effect of Cr and CrFe particles on the braking behavior of Cu-based powder metallurgy brake pads. Tribol. Trans. 62, 1072–1085 (2019). https://doi.org/10.1080/10402004.2019.1648914

Vladescu, S.C., Olver, A.V., Pegg, I.G., Reddyhoff, T.: The effects of surface texture in reciprocating contacts—an experimental study. Tribol. Int. 82, 28–42 (2015). https://doi.org/10.1016/j.triboint.2014.09.015

Zenebe Segu, D., Hwang, P.: Friction control by multi-shape textured surface under pin-on-disc test. Tribol. Int. 91, 111–117 (2015). https://doi.org/10.1016/j.triboint.2015.06.028

Xing, Y., Deng, J., Feng, X., Yu, S.: Effect of laser surface texturing on Si3N4/TiC ceramic sliding against steel under dry friction. Mater. Des. 1980–2015(52), 234–245 (2013). https://doi.org/10.1016/j.matdes.2013.05.077

Wu, Y.K., Mo, J.L., Tang, B., Xu, J.W., Huang, B., Xiang, Z.Y.: Tribological and dynamical analysis of a brake pad with multiple blocks for a high-speed train. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 234, 1771–1788 (2019). https://doi.org/10.1177/1350650119896456

Xiao, Y., Zhang, Z., Yao, P., Fan, K., Deng, M.: Mechanical and tribological behaviors of copper metal matrix composites for brake pads used in high-speed trains. Tribol. Int. 119, 585–592 (2018). https://doi.org/10.1016/j.triboint.2017.11.038

Wang, F., Gu, K.K., Wang, W.J.: Study on braking tribological behaviors of brake shoe material under the wet condition. Wear 342–343, 262–269 (2015). https://doi.org/10.1016/j.wear.2015.09.003

Shi, L.B., Wang, F., Ma, L., Liu, Q.Y., Guo, J., Wang, W.J.: Study of the friction and vibration characteristics of the braking disc/pad interface under dry and wet conditions. Tribol. Int. 127, 533–544 (2018). https://doi.org/10.1016/j.triboint.2018.07.012

Hoffmann, N.P., Gaul, L.: Friction induced vibrations of brakes: research fields and activities. Sae Tech. Pap. (2008). https://doi.org/10.4271/2008-01-2579

Massi, F., Berthier, Y., Baillet, L.: Contact surface topography and system dynamics of brake squeal. Wear 265, 1784–1792 (2008). https://doi.org/10.1016/j.wear.2008.04.049

Majcherczak, D., Dufrénoy, P., Naït-Abdelaziz, M.: Third body influence on thermal friction contact problems: application to braking. J. Tribol. 127, 89–95 (2007). https://doi.org/10.1115/1.1757490

Graf, M., Ostermeyer, G.P.: Instabilities in the sliding of continua with surface inertias: an initiation mechanism for brake noise. J. Sound Vib. 330, 5269–5279 (2011). https://doi.org/10.1016/j.jsv.2011.06.002

Tonazzi, D., Passafiume, M., Papangelo, A., Hoffmann, N., Massi, F.: Numerical and experimental analysis of the bi-stable state for frictional continuous system. Nonlinear Dyn. 102, 1361–1374 (2020). https://doi.org/10.1007/s11071-020-05983-y

Lee, S., Jang, H.: Effect of plateau distribution on friction instability of brake friction materials. Wear 400–401, 1–9 (2018). https://doi.org/10.1016/j.wear.2017.12.015

Stender, M., Tiedemann, M., Spieler, D., Schoepflin, D., Hoffmann, N., Oberst, S.: Deep learning for brake squeal: brake noise detection, characterization and prediction. Mech. Syst. Signal Process. 149, 107181 (2021). https://doi.org/10.1016/j.ymssp.2020.107181

Massi, F., Baillet, L., Giannini, O., Sestieri, A.: Brake squeal: Linear and nonlinear numerical approaches. Mech. Syst. Signal Process. 21, 2374–2393 (2007). https://doi.org/10.1016/j.ymssp.2006.12.008

Tison, T., Heussaff, A., Massa, F., Turpin, I., Nunes, R.F.: Improvement in the predictivity of squeal simulations: uncertainty and robustness. J. Sound Vib. 333, 3394–3412 (2014). https://doi.org/10.1016/j.jsv.2014.03.011

Sinou, J.J., Besset, S., Lenoir, D.: Some unexpected thermal effects on squeal events observed on the experimental bench FIVE@ECL. Mech. Syst. Signal Process. 160, 107867 (2021). https://doi.org/10.1016/j.ymssp.2021.107867

Bergman, F., Eriksson, M., Jacobson, S.: Influence of disc topography on generation of brake squeal. Wear 225–229, 621–628 (1999). https://doi.org/10.1016/S0043-1648(99)00064-2

Seol, C.J., Jongyun, J., Woo, K.H., Sun, L.H., Woo, P.Y., Junghwan, L.: Development of noise propensity index (NPI) for robust brake friction. SAE Int. J. Commer. Veh. 10, 589–595 (2017). https://doi.org/10.4271/2017-01-2529

Zhu, Z.Y., Mo, J.L., Wang, D.W., Zhao, J., Zhu, M.H., Zhou, Z.R.: Study on the correlation between dynamical behavior and friction/wear mechanism under the effect of grooves. J. Mater. Eng. Perform. 27(6), 2875–2884 (2018). https://doi.org/10.1007/s11665-018-3373-z

Tonazzi, D., Massi, F., Baillet, L., Culla, A., Di Bartolomeo, M., Berthier, Y.: Experimental and numerical analysis of frictional contact scenarios: from macro stick-slip to continuous sliding. Meccanica 50(3), 1–16 (2014). https://doi.org/10.1007/s11012-014-0010-2

Wang, D.W., Mo, J.L., Zhu, Z.Y., Ouyang, H., Zhu, M.H., Zhou, Z.R.: Debris trapping and space-varying contact via surface texturing for enhanced noise performance. Wear 396–397, 86–97 (2018). https://doi.org/10.1016/j.wear.2017.11.013

Xiang, Z.Y., Mo, J.L., Ouyang, H., Massi, F., Tang, B., Zhou, Z.R.: Contact behaviour and vibrational response of a high-speed train brake friction block. Tribol. Int. 152, 106540 (2020). https://doi.org/10.1016/j.triboint.2020.106540

Fan, Z.Y., Xiang, Z.Y., Tang, B., Chen, W., Qian, H.H., Mo, J.L.: Effect of surface modification on the tribological properties of friction blocks in high-speed train brake systems. Tribol. Lett. 69, 27 (2021). https://doi.org/10.1007/s11249-021-01402-4

Kim, J.W., Joo, B.S., Jang, H.: The effect of contact area on velocity weakening of the friction coefficient and friction instability: a case study on brake friction materials. Tribol. Int. 135, 38–45 (2019). https://doi.org/10.1016/j.triboint.2019.02.034

Yao, P.P., Xiao, Y.L., Deng, J.W.: Study on space copper-based powder metallurgy friction material and its tribological properties. Adv. Mater. Res. 284–286, 479–487 (2011). https://doi.org/10.4028/www.scientific.net/AMR.284-286.479

Wu, W., Shao, T.M., Chen, G.M.: Influence of groove surface texture on temperature rise under dry sliding friction. Sci China Technol. Sci. 02, 5–12 (2016). https://doi.org/10.1007/s11431-015-5920-2

Chen, G.X., Zhou, Z.R.: A self-excited vibration model based on special elastic vibration modes of friction systems and time delays between the normal and friction forces: a new mechanism for squealing noise. Wear 262, 1123–1139 (2007). https://doi.org/10.1016/j.wear.2006.11.014

Wang, D.W., Mo, J.L., Zhang, Q., Zhao, J., Ouyang, H., Zhou, Z.R.: The effect of the grooved elastic damping component in reducing friction-induced vibration. Tribol. Int. 110, 264–277 (2017). https://doi.org/10.1016/j.triboint.2017.02.031

Tonazzi, D., Massi, F., Culla, A., Baillet, L., Fregolent, A., Berthier, Y.: Instability scenarios between elastic media under frictional contact. Mech. Syst. Signal Process. 40, 754–766 (2013). https://doi.org/10.1016/j.ymssp.2013.05.022

Tonazzi, D., Massi, F., Baillet, L., Brunetti, J., Berthier, Y.: Interaction between contact behaviour and vibrational response for dry contact system. Mech. Syst. Signal Process. 110, 110–121 (2018). https://doi.org/10.1016/j.ymssp.2018.03.020

Acknowledgements

The authors are grateful for the financial support of the National Natural Science Foundation of China (Grant No. 51822508), the Sichuan Province Science and Technology Support Program (Grant No. 2020JDTD0012), the Independent Research Projects of State Key Laboratory of Traction Power (Grant No. 2020TPL-T06) and the Fundamental Research Funds for the Central Universities (Grant No. 2682021CX028).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yin, J.B., Wu, Y.K., Lu, C. et al. The Influence of Friction Blocks Connection Configuration on High-Speed Railway Brake Systems Performance. Tribol Lett 69, 122 (2021). https://doi.org/10.1007/s11249-021-01497-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-021-01497-9