Abstract

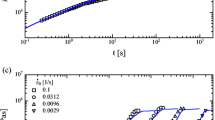

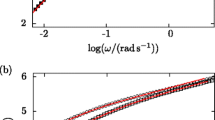

Branched polymers stress relaxation is at the center to their function as viscosity modifiers, though the fundamentals that underlie the correlation between the polymer topology and their impact on viscosity remains an open question. Here, the stress relaxation of short, branched polyethylene comb polymer melts is studied by molecular dynamics simulations. A coarse-grained model where four methylene groups constitute one bead is used, and the results are transposed to the atomistic level. For arms of length comparable to entanglement length ne of the linear polymer, we show that while increasing the number of branches with the same arm length decreases the plateau modulus, the terminal diffusive time does not change significantly. Increasing the arm length decreases the plateau modulus and increases the terminal time. As arms shorter than ne relax by the entanglement time, both the chain mobility and stress relaxation can be described by reptation of the backbone with an increased tube diameter and an increased friction coefficient; or in other words, the branches act as a solvent.

Graphic Abstract

Similar content being viewed by others

References

McLeish, T.C., Milner, S.T.: Entangled dynamics and melt flow of branched polymers. In: Roovers, J. (ed.) Branched Polymers II Advances in Polymer Science, pp. 195–256. Springer, Berlin (1999)

Snijkers, F., Pasquino, R., Olmsted, P., Vlassopoulos, D.: Perspectives on the viscoelasticity and flow behavior of entangled linear and branched polymers. J. Phys. Condens. Matter 27, 473002 (2015)

Matyjaszewski, K.: Architecturally complex polymers with controlled heterogeneity. Science 333, 1104–1105 (2011)

Fujimoto, T., Narukawa, H., Nagasawa, M.: Viscoelastic properties of comb-shaped polystyrenes. Macromolecules 3, 57–64 (1970)

Roovers, J., Graessley, W.: Melt rheology of some model comb polystyrenes. Macromolecules 14, 766–773 (1981)

Daniels, D., McLeish, T., Crosby, B., Young, R., Fernyhough, C.: Molecular rheology of comb polymer melts. 1. Linear viscoelastic response. Macromolecules 34, 7025–7033 (2001)

Lohse, D., Milner, S., Fetters, L., Xenidou, M., Hadjichristidis, N., Mendelson, R., Garcia-Franco, C., Lyon, M.: Well-defined, model long chain branched polyethylene. 2. Melt rheological behavior. Macromolecules 35, 3066–3075 (2002)

Kapnistos, M., Vlassopoulos, D., Roovers, J., Leal, L.: Linear rheology of architecturally complex macromolecules: comb polymers with linear backbones. Macromolecules 38, 7852–7862 (2005)

Stange, J., Uhl, C., Münstedt, H.: Rheological behavior of blends from a linear and a long-chain branched polypropylene. J. Rheo. 49, 1059–1079 (2005)

Stadler, F.J., Gabriel, C., Münstedt, H.: Influence of short-chain branching of polyethylenes on the temperature dependence of rheological properties in shear. Macromol. Chem. Phys. 208, 2449–2454 (2007)

Inkson, N., Graham, R., McLeish, T., Groves, D., Fernyhough, C.: Viscoelasticity of monodisperse comb polymer melts. Macromolecules 39, 4217–4227 (2006)

Wagner, M.H., Rolón-Garrido, V.H., Hyun, K., Wilhelm, M.: Analysis of medium amplitude oscillatory shear data of entangled linear and model comb polymers. J. Rheol. 55, 495–516 (2011)

Kempf, M., Ahirwal, D., Cziep, M., Wilhelm, M.: Synthesis and linear and nonlinear melt rheology of well-defined comb architectures of PS and PpMS with a low and controlled degree of long-chain branching. Macromolecules 46, 4978–4994 (2013)

Abbasi, M., Faust, L., Riazi, K., Wilhelm, M.: Linear and extensional rheology of model branched polystyrenes: from loosely grafted combs to bottlebrushes. Macromolecules 50, 5964–5977 (2017)

Haugan, I.N., Maher, M.J., Chang, A.B., Lin, T.-P., Grubbs, R.H., Hillmyer, M.A., Bates, F.S.: Consequences of grafting density on the linear viscoelastic behavior of graft polymers. ACS Macro Lett. 7, 525–530 (2018)

de Gennes, P.-G.: Reptation of a polymer chain in the presence of fixed obstacles. J. Chem. Phys. 55, 572–579 (1971)

Doi, M., Edwards, S.F.: The Theory of Polymer Dynamics. Oxford University, Oxford (1986)

Yurasova, T., McLeish, T., Semenov, A.: Stress relaxation in entangled comb polymer melts. Macromolecules 27, 7205–7211 (1994)

Bacová, P., Lentzakis, H., Read, D.J., Moreno, A.J., Vlassopoulos, D., Das, C.: Branch-point motion in architecturally complex polymers: estimation of hopping parameters from computer simulations and experiments. Macromolecules 47, 3362–3377 (2014)

Bačová, P., Moreno, A.J.: Real-space analysis of branch point motion in architecturally complex polymers. Macromolecules 47, 6955–6963 (2014)

Zhou, Q., Larson, R.G.: Direct molecular dynamics simulation of branch point motion in asymmetric star polymer melts. Macromolecules 40, 3443–3449 (2007)

Wijesinghe, S., Perahia, D., Grest, G.S.: Polymer topology effects on dynamics of comb polymer melts. Macromolecules 51, 7621–7628 (2018)

Salerno, K.M., Agrawal, A., Peters, B.L., Perahia, D., Grest, G.S.: Dynamics in entangled polyethylene melts. Eur. Phys. J. Special Top. 225, 1707–1722 (2016)

Grest, G.S., Michael Salerno, K., Peters, B.L., Ge, T., Perahia, D.: Resolving properties of entangled polymers melts through atomistic derived coarse-grained models. In: Andreoni, W., Yip, S. (eds.) Handbook of Materials Modeling: Methods: Theory and Modeling, pp. 1397–1410. Springer, Cham (2020)

Salerno, K.M., Agrawal, A., Perahia, D., Grest, G.S.: Resolving dynamic properties of polymers through coarse-grained computational studies. Phys. Rev. Lett. 116, 058302 (2016)

Peters, B.L., Salerno, K.M., Agrawal, A., Perahia, D., Grest, G.S.: Coarse grained modeling of polyethylene melts: effect on dynamics. J. Chem. Theory Comput. 13, 2890–2896 (2017)

Jorgensen, W.L., Madura, J.D., Swenson, C.J.: Optimized intermolecular potential functions for liquid hydrocarbons. J. Am. Chem. Soc. 106, 6638–6646 (1984)

Jorgensen, W.L., Maxwell, D.S., TiradoRives, J.: Development and testing of the OPLS all-atom force field on conformational energetics and properties of organic liquids. J. Am. Chem. Soc. 118, 11225–11236 (1996)

Siu, S.W., Pluhackova, K., Böckmann, R.A.: Optimization of the OPLS-AA force field for long hydrocarbons. J. Chem. Theory Comput. 8, 1459–1470 (2012)

Schneider, T., Stoll, E.: Molecular-dynamics study of a three-dimensional one-component model for distortive phase transitions. Phys. Rev. B 17, 1302–1322 (1978)

Grest, G.S., Kremer, K.: Molecular dynamics simulations for polymers in the presence of a heat bath. Phys. Rev A 33, 3628–3631 (1986)

Plimpton, S.: Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 117, 1–19 (1995)

Fetters, L., Lohse, D., Richter, D., Witten, T., Zirkel, A.: Connection between polymer molecular weight, density, chain dimensions, and melt viscoelastic properties. Macromolecules 27, 4639–4647 (1994)

Fetters, L.J., Lohse, D.J., Milner, S.T., Graessley, W.W.: Packing length influence in linear polymer melts on the entanglement, critical, and reptation molecular weights. Macromolecules 32, 6847–6851 (1999)

Vega, J.F., Rastogi, S., Peters, G.W.M., Meijer, H.E.H.: Rheology and reptation of linear polymers. Ultrahigh molecular weight chain dynamics in the melt. J. Rheol. 48, 663–678 (2004)

Hsu, H.-P., Kremer, K.: Static and dynamic properties of large polymer melts in equilibrium. J. Chem. Phys. 144, 154907 (2016)

Peters, B.L., Salerno, K.M., Ge, T., Perahia, D., Grest, G.S.: Viscoelastic response of dispersed entangled polymer melts. Macromolecules 53, 8400–8405 (2020)

Treloar, L.R.G.: The Physics of Rubber Elasticity. Oxford University Press, Oxford (1975)

Kremer, K., Grest, G.S.: Dynamics of entangled linear polymer melts: a molecular-dynamics simulation. J. Chem. Phys. 92, 5057–5086 (1990)

Likhtman, A.E., McLeish, T.C.: Quantitative theory for linear dynamics of linear entangled polymers. Macromolecules 35, 6332–6343 (2002)

Marrucci, G.: Relaxation by reptation and tube enlargement: a model for polydisperse polymers. J Polym. Sci. B 23, 159–177 (1985)

Hou, J.-X., Svaneborg, C., Everaers, R., Grest, G.S.: Stress relaxation in entangled polymer melts. Phys. Rev. Lett. 105, 068301 (2010)

Acknowledgement

We dedicate this paper to the memory of Mark O. Robbins, graduate advisor to two of us (TG and KMS), friend and colleague to all. D. Perahia kindly acknowledged NSF DMR 1905407 for partial support. T. Ge acknowledges start-up funds from the University of South Carolina. This research used resources of the National Energy Research Scientific Computing Center (NERSC), a U.S. Department of Energy Office of Science User Facility operated under Contract No. DE-AC02-05CH11231. This work was performed, in part, at the Center for Integrated Nanotechnologies, an Office of Science User Facility operated for the U.S. Department of Energy (DOE) Office of Science. Sandia National Laboratories is a multimission laboratory managed and operated by the National Technology and Engineering Solutions of Sandia, LC, a wholly owned subsidiary of Honeywell International, Inc., for the U.S. Department of Energy’s National Nuclear Security Administration under contract no. DE-NA-0003525. The views expressed in the article do not necessarily represent the views of the U.S. DOE or the United States Government.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wijesinghe, S., Perahia, D., Ge, T. et al. Stress Relaxation of Comb Polymer Melts. Tribol Lett 69, 59 (2021). https://doi.org/10.1007/s11249-021-01432-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-021-01432-y