Abstract

The friction coefficient, an important parameter to evaluate the dynamic properties of friction pairs, has been widely used in macro engineering fields. However, it is probably inappropriate to characterize the tribological properties at the nanoscale due to the strong size effect, and the conventional formula cannot reveal its determinants owing to its oversimple form. Therefore, in the present work, a new formula is deduced to overcome these shortcomings. The established formula for the friction coefficient considers the adhesion and discloses the relationship between the friction coefficient and the material properties of diamond. It effectively suppresses the dependency of the friction coefficient on the load, although such a dependency cannot be eliminated completely. Therefore, another new formula, independent of the loading force, is derived. Interestingly, the results indicate that the size effect is invariably observed in the friction coefficients derived from the three formulas due to different accumulation effects of debris atoms, which is verified by molecular dynamics simulations.

Graphic Abstract

Similar content being viewed by others

References

Kumar, N., Sankaran, K.J., Kozakov, A.T., Sidashov, A.V., Nicolskii, A.V., Haenen, K., Kolesnikov, V.I.: Surface and bulk phase analysis of the tribolayer of nanocrystalline diamond films sliding against steel balls. Diam. Relat. Mater. 97, 107472 (2019)

Field, J.E.: The mechanical and strength properties of diamond. Rep. Prog. Phys. 75(12), 126505 (2012)

Tyagi, A., Walia, R.S., Murtaza, Q.: Tribological behavior of temperature dependent environment friendly thermal CVD diamond coating. Diam. Relat. Mater. 96, 148–159 (2019)

Ramaswamy, S.H., Shimizu, J., Chen, W., Kondo, R., Choi, J.: Investigation of diamond-like carbon films as a promising dielectric material for triboelectric nanogenerator. Nano Energy. 60, 875–885 (2019)

Sakurai, K., Hiratsuka, M., Nakamori, H., Namiki, K., Hirakuri, K.: Evaluation of sliding properties and durability of DLC coating for medical Devices. Diam. Relat. Mater. 96, 97–103 (2019)

Gaydaychuk, A., Linnik, S.: Tribological and mechanical properties of diamond films synthesized with high methane concentration. Int. J. Refract. Met. Hard Mater. 85, 105057 (2019)

Grillo, S.E., Field, J.E.: The friction of CVD diamond at high Hertzian stresses: The effect of load, environment and sliding velocity. J. Phys. D. Appl. Phys. 33(6), 595–602 (2000)

Konicek, A.R., Grierson, D.S., Gilbert, P.U.P.A., Sawyer, W.G., Sumant, A.V., Carpick, R.W.: Origin of ultralow friction and wear in ultrananocrystalline diamond. Phys. Rev. Lett. 100, 235502 (2008)

Panda, K., Rani, R., Kumar, N., Sankaran, K.J., Park, J.Y., Ganesan, K., Lin, I.N.: Dynamic friction behavior of ultrananocrystalline diamond films: A depth resolved chemical phase analysis. Ceram. Int. 45(17), 23418–23422 (2019)

Yue, T., Yue, W., Qin, W., Liu, P., Wang, C.: Effects of environmental atmospheres on tribological behaviors of sintered polycrystalline diamond sliding against silicon nitride. Int. J. Refract. Met. Hard Mater. 81, 85–93 (2019)

Grillo, S.E., Field, J.E.: Very low friction for natural diamond in water of different pH values. Eur. Phys. J. B. 13(3), 405–408 (2000)

Kuwahara, T., Moras, G., Moseler, M.: Friction regimes of water-lubricated diamond (111): Role of interfacial ether groups and tribo-induced aromatic surface reconstructions. Phys. Rev. Lett. 119, 096101 (2017)

Feng, Z., Field, J.E.: The friction and wear of diamond sliding on diamond. J. Phys. D. Appl. Phys. 25(1A), A33–A37 (1992)

Grillo, S.E., Field, J.E., van Bouwelen, F.M.: Diamond polishing: The dependency of friction and wear on load and crystal orientation. J. Phys. D. Appl. Phys. 33(8), 985–990 (2000)

Yan, G., Wu, Y., Cristea, D., Liu, L., Tierean, M., Wang, Y., Lu, F., Wang, H., Yuan, Z., Munteanu, D., Zhao, D.: Mechanical properties and wear behavior of multi-layer diamond films deposited by hot-filament chemical vapor deposition. Appl. Surf. Sci. 494, 401–411 (2019)

Carpinteri, A., Paggi, M.: Size-scale effects on the friction coefficient. Int. J. Solids Struct. 42(9–10), 2901–2910 (2005)

Sikder, A.K.: Effect of tip size and experimental conditions on nano-scale friction testing. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 0(0), 1–10 (2020). https://doi.org/10.1177/1350650120950088

Xie, G., Zheng, B., Li, W., Xue, W.: Tribological behavior of diamond-like carbon film with different tribo-pairs: A size effect study. Appl. Surf. Sci. 254(21), 7022–7028 (2008)

Geoffrey, J.G., Sidney, R.C., Gabi, N., Gary, M.M., Hajime, S., Coulman, D.: Atomic scale friction of a diamond tip on diamond (100) and (111) surfaces. J. Appl. Phys. 73(1), 163–167 (1993)

Zhang, F., Meng, B., Geng, Y., Zhang, Y., Li, Z.: Friction behavior in nanoscratching of reaction bonded silicon carbide ceramic with Berkovich and sphere indenters. Tribol. Int. 97, 21–30 (2016)

Li, X., Wang, A., Lee, K.R.: Insights on low-friction mechanism of amorphous carbon films from reactive molecular dynamics study. Tribol. Int. 131, 567–578 (2019)

Yin, N., Zhang, Z., Zhang, J.: Frictional contact between the diamond tip and graphene step edges. Tribol. Lett. 67(3), 75 (2019)

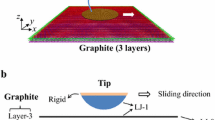

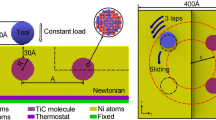

Liu, H.Z., Zong, W.J., Cheng, X.: Origins for the anisotropy of the friction force of diamond sliding on diamond. Tribol. Int. 148, 106298 (2020)

Bowden, F.P., Tabor, D.: Friction and Lubrication of Solids, Part II (Reprint). Oxford University Press, London (2001)

Pethica, J.B., Oliver, W.C.: Tip surface interactions in STM and AFM. Phys. Scr. T19A, 61–66 (1987)

Telling, R.H., Pickard, C.J., Payne, M.C., Field, J.E.: Theoretical strength and cleavage of diamond. Phys. Rev. Lett. 84(22), 5160–5163 (2000)

Field, J.E., Pickles, C.S.J.: Strength, fracture and friction properties of diamond. Diam. Relat. Mater. 5(6-8), 625–634 (1996)

Muller, V.M., Yushchenko, V.S., Derjaguin, B.V.: On the influence of molecular forces on the deformation of an elastic sphere and its sticking to a rigid plane. Prog. Surf. Sci. 45(1–4), 157–167 (1994)

Gutowski, W.: Thermodynamics of adhesion. In: Lee, L.H. (ed.) Fundamentals of Adhesion, pp. 87–135. Plenum Press, New York (1991)

Johnson, K.L., Kendall, K., Roberts, A.D.: Surface energy and contact of elastic solids. Proc. R. Soc. A. 324, 301–303 (1971)

Wang, F., Zhao, X.: Effect of contact stiffness on wedge calibration of lateral force in atomic force microscopy. Rev. Sci. Instrum. 78, 043701 (2007)

Lee, L.H.: The chemistry and physics of solid adhesion. In: Lee, L.H. (ed.) Fundamentals of Adhesion, pp. 1–86. Plenum Press, New York (1991)

Cui, Z.P., Li, G., Zong, W.J.: A polishing method for single crystal diamond (100) plane based on nano silica and nano nickel powder. Diam. Relat. Mater. 95, 141–153 (2019)

Varenberg, M., Etsion, I., Halperin, G.: An improved wedge calibration method for lateral force in atomic force microscopy. Rev. Sci. Instrum. 74(7), 3362–3367 (2003)

Nie, A., Bu, Y., Li, P., Zhang, Y., Jin, T., Liu, J., Zhang, S., Wang, Y., He, J., Liu, Z., Wang, H., Tian, Y., Yang, W.: Approaching diamond’s theoretical elasticity and strength limits. Nat. Commun. 10, 5533 (2019)

Samuels, B., Wilks, J.: The friction of diamond sliding on diamond. J. Mater. Sci. 23(8), 2846–2864 (1988)

Butt, H.J., Graf, K., Kappl, M.: Physics and Chemistry of Interfaces. betzdruck GmbH, Darmstadt (2003)

Milne, Z.B., Schall, J.D., Jacobs, T.D.B., Harrison, J.A., Carpick, R.W.: Covalent bonding and atomic-level plasticity increase adhesion in silicon-diamond nanocontacts. ACS Appl. Mater. Interfaces. 11(43), 40734–40748 (2019)

Bowden, F.P., Brookes, C.A.: Frictional anisotropy in nonmetallic crystals. Proc. R. Soc. A. 295(1442), 244–258 (1966)

Broitman, E.: The nature of the frictional force at the macro-, micro-, and nano-scales. Friction. 2(1), 40–46 (2014)

Enachescu, M.: Nanoscale effects of friction, adhesion and electrical conduction in AFM experiments. In: Bellitto, V. (ed.) Atomic Force Microscopy – Imaging, Measuring and Manipulating Surfaces at the Atomic Scale, pp. 99–146. InTech (2012)

Tersoff, J.: Empirical interatomic potential for carbon, with applications to amorphous carbon. Phys. Rev. Lett. 61(25), 2879–2882 (1988)

Zong, W.J., Cheng, X., Zhang, J.J.: Atomistic origins of material removal rate anisotropy in mechanical polishing of diamond crystal. Carbon. 99, 186–194 (2016)

Plimpton, S.: Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 117(1), 1–19 (1995)

Stukowski, A.: Visualization and analysis of atomistic simulation data with OVITO-the Open Visualization Tool. Model. Simul. Mater. Sci. Eng. 18(1), 015012 (2010)

van Bouwelen, F.M.: Diamond polishing from different angles. Diam. Relat. Mater. 9(3), 925–928 (2000)

Maras, E., Trushin, O., Stukowski, A., Ala-Nissila, T., Jónsson, H.: Global transition path search for dislocation formation in Ge on Si(001). Comput. Phys. Commun. 205, 13–21 (2016)

Zong, W.J., Li, D., Cheng, K., Sun, T., Wang, H.X., Liang, Y.C.: The material removal mechanism in mechanical lapping of diamond cutting tools. Int. J. Mach. Tools Manuf. 45(7–8), 783–788 (2005)

Acknowledgments

The authors would like to thank the Science Challenge Project (No. TZ2018006-0202-02) and the National Natural Science Foundation of China (No. 51675133) for their support of this work. The authors would also like to thank A. Prof Yanquan Geng for his help with the AFM experiments.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, H., Zong, W. & Cheng, X. Load- and Size Effects of the Diamond Friction Coefficient at the Nanoscale. Tribol Lett 68, 120 (2020). https://doi.org/10.1007/s11249-020-01360-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-020-01360-3