Abstract

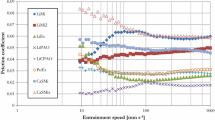

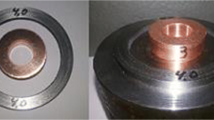

Many grease-lubricated machinery components operate in wet environments, making them susceptible to water contamination. It has been reported that the presence of a mere 1% water contamination in grease reduces the life of a bearing by 90%. Yet there are only a few standards available to characterize grease performance in the presence of water, most of which are primarily qualitative, providing inconclusive information, often relative to standard samples, at a significant cost in time and materials. In this paper, a unique approach is proposed for evaluating grease capability for repelling water. The method utilizes the contact angle of a water droplet on a grease surface to quantify grease water resistance. It is hypothesized that the higher the hydrophobic nature of the grease, the greater the resistance to water and vice versa. The validation of the hypothesis is established by performing extensive contact angle measurements on seven types of commercially available greases. The efficacy of contact angle results is established by measuring the change in the yield stress values obtained using a rheometer. From the obtained results, it is shown that the proposed approach is reliable and capable of distinguishing greases as water repellent/attractive.

Graphic Abstract

Similar content being viewed by others

References

Lijesh, K.P., Khonsari M.M.: Procedure for evaluating the mechanical degradation of a grease. NLGI Spokesman 84(1), 24–35 (2020)

Chuck, C.: Grease: a niche market opportunity. Tribol. Lubr. Technol. 71(5), 32–39 (2015)

Cyriac, F., Lugt, P.M., Bosman, R.: Impact of water on the rheology of lubricating greases. Tribol. Trans. 59(4), 679–689 (2016)

Zhou, Y., Bosman, R., Lugt, P.M.: On the shear stability of dry and water-contaminated calcium sulfonate complex lubricating greases. Tribol. Trans. 62(4), 626–634 (2019)

Duncanson, M.: Machinery Lubrication: detecting and controlling water in oil. Machinery lubrication, 2005

Eachus, A.C.: The trouble with water. Tribology Lubr. Technol. 61(10), 32–38 (2005)

Noria Corporation. Water in Oil Contamination. Machinery Lubrication. 2001

Dittes, N., Marklund, P., Anders Pettersson, A.: Mixing grease with water, in Proceedings of the 1st European Conference on Improvement in Bearing Technology through European Research Collaboration (iBETTER), SKF Engineering and Research Center Nieuwegein, The Netherlands, 2015

Li, J., Cheng, S., Zhao, W., Baojie, W.: The typical application of calcium sulfonate complex greases in steel mills. NLGI Spokesman 82(1), 32–38 (2018)

Leckner, J.: Water + Grease = Fatal Attraction?. Proceedings of the 25th ELGI Annual General Meeting, Amsterdam, 20–23, 2013

Mistry, A.: Performance of lubricating greases in the presence of water. NLGI Spokesman 68(12), 8–15 (2005)

Nagarkoti, A.S.: Water resistance properties of grease–an outlook. In: NLGI-India 12th Lubricating grease conference, 28–30, 2010

Cann, P.M.: Starved grease lubrication of rolling rontacts. Tribol. Trans. 42(4), 867–873 (1999)

Alan, G., Khonsari, M.: An overview of grease water resistance. Lubricants 8(9), 86 (2020)

Lugt, P.M.: Modern advancements in lubricating grease technology. Tribol. Int. 97, 467–477 (2016)

Cyriac, F., Lugt, P.M., Bosman, R.: On a new method to determine the yield stress in lubricating grease. Tribol. Trans. 58(6), 1021–1030 (2015)

Cyriac, F., Lugt, P.M., Bosman, R., Venner, C.H.: Impact of water on EHL film thickness of lubricating greases in rolling point contacts. Tribol. Lett. 61(3), 23 (2016)

Bosman, R., Lugt, P.M.: The microstructure of calcium sulfonate complex lubricating grease and its change in the presence of water. Tribol. Trans. 61(5), 842–849 (2018)

Prabhu, K.N., Fernades, P., Kumar, G.: Effect of substrate surface roughness on wetting behaviour of vegetable oils. Mater. Des. 30(2), 297–305 (2009)

Wang, Q.Y., Yang, H.F., Han, Q.G., Fang, L., Ge, S.R.: Tribological and lubrication properties of sandblast-textured surfaces with varied roughness. Adv. Mater. Res. 154, 1019–1022 (2011)

Sakai, M., Yanagisawa, T., Nakajima, A., Kameshima, Y., Okada, K.: Effect of surface structure on the sustainability of an air layer on superhydrophobic coatings in a water–ethanol mixture. Langmuir 25(1), 13–16 (2009)

Son, Y., Kim, C., Yang, D.H., Ahn, D.J.: Spreading of an inkjet droplet on a solid surface with a controlled contact angle at low Weber and Reynolds numbers. Langmuir 24(6), 2900–2907 (2008)

Perelaer, J., Hendriks, C.E., de Laat ntonius, W.M., Schubert, U.S.: One-step inkjet printing of conductive silver tracks on polymer substrates. Nanotechnology (2009). https://doi.org/10.1088/0957-4484/20/16/165303

Yang, H., Jiang, P.: Self-cleaning diffractive macroporous films by doctor blade coating. Langmuir 26(15), 12598–12604 (2010)

Bhushan, B., Jung, Y.C., Koch, K.: Self-cleaning efficiency of artificial superhydrophobic surfaces. Langmuir 25(5), 3240–3248 (2009)

Rauscherand, M., Dietrich, S.: Wetting phenomena in nanofluidics. Annu. Rev. Mater. Res. 38, 143–172 (2008)

Fei, K., Chiu, C.P., Hong, C.W.: Molecular dynamics prediction of nanofluidic contact angle offset by an AFM. Microfluid. Nanofluid. 4(4), 321 (2008)

Nanayakkara, Y.S., Perera, S., Bindiganavale, S., Wanigasekara, E., Moon, H., Armstrong, D.W.: The effect of AC frequency on the electrowetting behavior of ionic lsiquids. Anal. Chem. 82(8), 3146–3154 (2010)

Mortazavi, V., Khonsari, M.M.: On the degradation of superhydrophobic surfaces: a review. Wear 372, 145–157 (2017)

Hasan, S.M.A., Mehta, N., McCarley, R.L., Khonsari, M.M., Gartia, M.R.: Wetting translucency of graphene on plasmonic nanohole arrays. 2D Mater. 7(1), 011004 (2019)

Ardalan, C., Prasad, A., Lijesh, K.P., Shaik, S., Ettefagh, A.H., Dasa, V., Guo, S., et al.: Improvement of tribological and biocompatibility properties of orthopedic materials using piezoelectric direct discharge plasma surface modification. ACS Biomater. Sci. Eng 5(5), 2147–2159 (2019)

Lijesh, K.P., Khonsari, M.M.: On the assessment of mechanical degradation of grease using entropy generation rate. Tribol. Lett. 67(50), 1–13 (2019)

Zhou, Y., Bosman, R., Lugt, P.M.: A master curve for the shear degradation of lubricating greases with a fibrous structure. Tribol. Trans. 62(1), 78–87 (2019)

Zakani, B., Ansari, M., Grecov, D.: Dynamic rheological properties of a fumed silica grease. Rheol. Acta 57(1), 83–94 (2018)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lijesh, K.P., Khonsari, M.M. & Miller, R.A. Assessment of Water Contamination on Grease Using the Contact Angle Approach. Tribol Lett 68, 103 (2020). https://doi.org/10.1007/s11249-020-01339-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-020-01339-0