Abstract

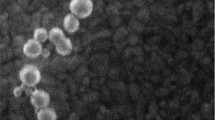

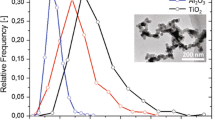

In this work, the nano- and macroscale tribological properties of maghemite (γ-Fe2O3) nanoparticles in aqueous solution are compared and contrasted for alumina contacts as a function of nanoparticle concentration. A quartz crystal microbalance (QCM) technique was used for nanotribology measurements and a ball-on-disk method was used to measure macroscale friction coefficients. Statistical methods were employed to identify significant associations between the QCM and ball-on-disk measurements, employing selected candidate performance factors for each system. In particular, the macroscale response was parameterized by % reduction in the friction coefficient while candidate QCM “bulk” and “surface” performance factors were selected from functions of the frequency f and resistance Rm shifts upon addition of nanoparticles to the water surrounding the QCM. Incremental increases in concentration were performed and reductions in friction and drag forces were observed for concentrations up to 0.6 wt%, after which further reductions were not observed. The factor δRfilm/δffilm exhibited a linear correlation with the reduction in macroscale friction coefficient, defined as the ratio of the shift in resistance to the shift in frequency attributable to interfacial effects and changes in the glide plane location. Atomic force microscopy was also utilized to both qualitatively and quantitatively determine surface roughness before and after particle uptake, leading to the observations that particles are easily removed from the surface and do not significantly alter surface morphology.

Similar content being viewed by others

References

Wu, H., Zhao, J., Xia, W., Cheng, X., He, A., Hui Wu, A., Yun, J.-H., Wang, L., Huang, H., Jiao, S., Huang, L., Zhang, S., Jiang, Z.: A study of the tribological behaviour of TiO2 nano- additive water-based lubricants Study on tribological behaviour of TiO 2 nano-additive water-based lubricants. Tribol. Int. 109, 398–408 (2017)

Osawa, E.: Nanodiamond-an emerging nano-carbon material. In: Somiya S. (ed.) Handbook of Advanced Ceramics: Materials, Applications, Processing, and Properties. pp. 89–102. Academic Press, Amsterdam (2013)

Torres-Sanchez, C., Balodimos, N.: Effective and eco-friendly lubrication protocol using nanodiamonds in a dry regime for conveyor systems in the beverage industry. 30, 209–218 (2017). https://doi.org/10.1002/pts.2294

Betton, C.I.: Lubricants and their environmental impact. In: Chemistry and Technology of Lubricants, pp. 282–298. Springer, Boston (1994)

Mortier, R.M., Fox, M.F., Orszulik, S.T.: Chemistry and Technology of Lubricants. Springer Dordrecht (2010)

Dai, W., Liang, H., Kheireddin, B., Gao, H.: Roles of nanoparticles in oil lubrication high-temperature nano-tribology properties of sub-20 nm coatings and thin films view project roles of nanoparticles in oil lubrication. (2017). https://doi.org/10.1016/j.triboint.2016.05.020

Chiñas-Castillo, F., Spikes, H.A.: Mechanism of action of colloidal solid dispersions. J. Tribol. 125, 552 (2003). https://doi.org/10.1115/1.1537752

Jacobson, S., Hogmark, S.: Surface modifications in tribological contacts. Wear. 266, 370–378 (2009). https://doi.org/10.1016/j.wear.2008.04.035

Liu, Z., Leininger, D., Koolivand, A., Smirnov, A.I., Shenderova, O., Brenner, D.W., Krim, J.: Tribological properties of nanodiamonds in aqueous suspensions: effect of the surface charge. RSC Adv. 5, 78933–78940 (2015). https://doi.org/10.1039/C5RA14151F

Curtis, C.K., Marek, A., Smirnov, A.I., Krim, J.: A comparative study of the nanoscale and macroscale tribological attributes of alumina and stainless steel surfaces immersed in aqueous suspensions of positively or negatively charged nanodiamonds. Beilstein J. Nanotechnol. 8, 2045–2059 (2017). https://doi.org/10.3762/bjnano.8.205

Acharya, B., Chestnut, M., Marek, A., Smirnov, A.I., Krim, J.: A combined QCM and AFM study exploring the nanoscale lubrication mechanism of silica nanoparticles in aqueous suspension. Tribol. Lett. 65, 115 (2017). https://doi.org/10.1007/s11249-017-0898-5

Lodge, M.S., Tang, C., Blue, B.T., Hubbard, W.A., Martini, A., Dawson, B.D., Ishigami, M.: Lubricity of gold nanocrystals on graphene measured using quartz crystal microbalance. Sci. Rep. 6, 31837 (2016). https://doi.org/10.1038/srep31837

Krim, J.: Friction and energy dissipation mechanisms in adsorbed molecules and molecularly thin films. Adv. Phys. 61, 155–323 (2012). https://doi.org/10.1080/00018732.2012.706401

Song, X., Qiu, Z., Yang, X., Gong, H., Zheng, S., Cao, B., Wang, H., Möhwald, H., Shchukin, D.: Submicron-lubricant based on crystallized Fe3O4 spheres for enhanced tribology performance. Chem. Mater. 26, 5113–5119 (2014). https://doi.org/10.1021/cm502426y

Barrau, O., Boher, C., Vergne, C., Rezai-Aria, F., Gras, R.: Investigations of friction and wear mechanisms of hot forging tool steels. Karlstad Univ. 1, 81–94 (2002)

Zhou, Y., Wang, S.Q., Chen, W., Jin, Y.X., Wang, L., Chen, K.M., Cui, X.H.: Effect of various nanoparticles on tribo-layers and wear behavior of TC11 alloy. Metall. Mater. Trans. A. 48, 3287–3299 (2017). https://doi.org/10.1007/s11661-017-4131-9

Colombié, C., Berthier, Y., Floquet, A., Vincent, L., Godet, M.: Fretting: load carrying capacity of wear debris. J. Tribol. 106, 194–201 (1984). https://doi.org/10.1115/1.3260881

Cornell, R.M., Schwertmann, U.: The Iron Oxides. Wiley (2003)

Thünemann, A.F., Schütt, D., Kaufner, L., Pison, U., Möhwald, H.: Maghemite nanoparticles protectively coated with poly(ethylene imine) and poly(ethylene oxide)-block-poly(glutamic acid). Langmuir. 22, 2351–2357 (2006). https://doi.org/10.1021/LA052990D

Jeong, J.R., Lee, S.J., Kim, J.D., Shin, S.C.: Magnetic properties of gamma-Fe2O3 nanoparticles made by coprecipitation method. Phys. Status Solidi Basic Res. 241, 1593–1596 (2004). https://doi.org/10.1002/pssb.200304549

Halliday, J.S., Hirst, W.: The fretting corrosion of mild steel. Proc. R. Soc. Lond. 236, 411–425 (1956)

Kato, H.: Severe-mild wear transition by supply of oxide particles on sliding surface. Wear. 255, 426–429 (2003). https://doi.org/10.1016/S0043-1648(03)00077-2

Kato, H., Komai, K.: Tribofilm formation and mild wear by tribo-sintering of nanometer-sized oxide particles on rubbing steel surfaces. Wear. 262, 36–41 (2007). https://doi.org/10.1016/j.wear.2006.03.046

Jiang, J., Stott, F.H., Stack, M.M.: The role of triboparticles in dry sliding wear. Tribol. Int. 31, 245–256 (1998)

Stott, F.H., Wood, G.C.: The influence of oxides on the friction and wear of alloys. Tribol. Int. 11, 211–218 (1978). https://doi.org/10.1016/0301-679X(78)90178-0

Kato, H.: Effects of supply of fine oxide particles onto rubbing steel surfaces on severe-mild wear transition and oxide film formation. Tribol. Int. 41, 735–742 (2008). https://doi.org/10.1016/j.triboint.2008.01.001

Hu, Z.S., Dong, J.X., Chen, G.X.: Study on antiwear and reducing friction additive of nanometer ferric oxide. Tribol. Int. 31, 355–360 (1998). https://doi.org/10.1016/S0301-679X(98)00042-5

Iwabuchi, A., Kubosawa, H., Hori, K.: The dependence of the transition from severe to mild wear on load and surface roughness when the oxide particles are supplied before sliding. Wear. 139, 319–333 (1990). https://doi.org/10.1016/0043-1648(90)90054-E

Iwabuchi, A., Hori, K., Kubosawa, H.: The effect of oxide particles supplied at the interface before sliding on the severe-mild wear transition. Wear. 128, 123–137 (1988). https://doi.org/10.1016/0043-1648(88)90179-2

Iwabuchi, A.: The role of oxide particles in the fretting wear of mild-steel. Wear. 151, 301–311 (1991). https://doi.org/10.1016/0043-1648(91)90257-u

Antonov, M., Afshari, H., Baronins, J., Adoberg, E., Raadik, T., Hussainova, I.: The effect of temperature and sliding speed on friction and wear of Si3N4, Al2O3, and ZrO2 balls tested against AlCrN PVD coating. Tribol. Int. 118, 500–514 (2018). https://doi.org/10.1016/j.triboint.2017.05.035

Parker, D.A.: Ceramics Technology—application to engine components. Proc. Inst. Mech. Eng. Part A. 199, 135–150 (1985). https://doi.org/10.1243/PIME_PROC_1985_199_020_02

Hubbe, M.: Steric Stabilization, https://projects.ncsu.edu/project/hubbepaperchem/Defnitns/StericSt.htm

Napper, D., Netschey, A.: Studies of the steric stabilization of colloidal particles. J. Colloid Interface Sci. 37, 528–535 (1971). https://doi.org/10.1016/0021-9797(71)90330-4

Lazarowich, R.J., Taborek, P., Yoo, B.-Y., Myung, N.V.: Fabrication of porous alumina on quartz crystal microbalances. J. Appl. Phys. 101, 104909 (2007). https://doi.org/10.1063/1.2730563

QCM200 Quartz Crystal Microbalance: Digital Controller-QCM25 5 MHz Crystal Oscillator, Revision 2

Qiao, X., Zhang, X., Tian, Y., Meng, Y.: Progresses on the theory and application of quartz crystal microbalance. Appl. Phys. Rev. 3, 031106 (2016). https://doi.org/10.1063/1.4963312

Pisov, S., Tosatti, E., Tartaglino, U., Vanossi, A.: Gold clusters sliding on graphite: a possible quartz crystal microbalance experiment? J. Phys. Condens. Matter. 19, 305015 (2007). https://doi.org/10.1088/0953-8984/19/30/305015

Highland, M., Krim, J.: Superconductivity dependent friction of water, nitrogen, and superheated He films adsorbed on Pb(111). Phys. Rev. Lett. 96, 226107 (2006). https://doi.org/10.1103/PhysRevLett.96.226107

Vlachová, J., König, R., Johannsmann, D.: Stiffness of sphere–plate contacts at MHz frequencies: dependence on normal load, oscillation amplitude, and ambient medium. Beilstein J. Nanotechnol. 6, 845–856 (2015). https://doi.org/10.3762/bjnano.6.87

Sauerbrey, G.: Use of quartz crystals for weighing thin layers and for weighing. Z. Phys. 155, 206–222 (1959). https://doi.org/10.1007/BF01337937

Kanazawa, K.K., Gordon, J.G.: Frequency of a quartz microbalance in contact with liquid. Anal. Chem. 57, 1770–1771 (1985). https://doi.org/10.1021/ac00285a062

Hanke, W., Petri, J., Johannsmann, D.: Partial slip in mesoscale contacts: dependence on contact size. Phys. Rev. E. 88, 1–14 (2013)

Huang, X., Bai, Q., Hu, J., Hou, D.: A practical model of quartz crystal microbalance. Sensors. 17, 1–9 (2017). https://doi.org/10.3390/s17081785

Mishra, P.C., Mukherjee, S., Nayak, S.K., Panda, A.: A brief review on viscosity of nanofluids. Int. Nano Lett. 4, 109–120 (2014). https://doi.org/10.1007/s40089-014-0126-3

Manikandan, S., Karthikeyan, N., Rajan, K.S.: Viscosity of Fe2O3 nanoparticles dispersion in water and ethylene glycol-water mixture (nanofluids). Int. J. Nanoparticles. 6, 10 (2013). https://doi.org/10.1504/IJNP.2013.051912

Krim, J., Heyvaert, I., Van Haesendonck, C., Bruynseraede, Y.: Scanning tunneling microscopy observation of self-affine fractal roughness in ion-bombarded film surfaces. Phys. Rev. Lett. 70, 57–60 (1993). https://doi.org/10.1103/PhysRevLett.70.57

Krim, J., Indekeu, J.O.: Roughness exponents: a paradox resolved. Phys. Rev. E. 48, 1576–1578 (1993). https://doi.org/10.1103/PhysRevE.48.1576

Palasantzas, G., Krim, J.: Scanning tunneling microscopy study of the thick film limit of kinetic roughening. Phys. Rev. Lett. 73, 3564–3567 (1994). https://doi.org/10.1103/PhysRevLett.73.3564

Becker, E.: Trends in tribological materials and engine technology. Tribol. Int. 37, 569–575 (2004)

Huang, K., Szlufarska, I.: Friction and slip at solid/liquid interface in vibrational systems Langmuir. 28, 17302–17312 (2012).

Huang, K., Szlufarska, I.: Green-Kubo relation for friction at liquid/solid interface. Physical Rev. E 89, 032119 (2016)

Eklund, E.A., Bruinsma, R., Rudnick, J., Williams, R.S.: Submicron-scale surface roughening induced by ion bombardment. Phys. Rev. Lett. 67, 1759 (1991)

Adachi, K., Kato, K.: Formation of smooth wear surfaces on alumina ceramics by embedding and tribo-sintering of fine wear particles. Wear. 245, 84–91 (2000). https://doi.org/10.1016/S0043-1648(00)00468-3

Xue, Q., Liu, W., Zhang, Z.: Friction and wear properties of a surface-modified TiO2 nanoparticle as an additive in liquid paraffin. Wear. 213, 29–32 (1997). https://doi.org/10.1016/S0043-1648(97)00200-7

Xiang, L., Gao, C., Wang, Y., Pan, Z., Hu, D.: Tribological and tribochemical properties of magnetite nanoflakes as additives in oil lubricants. Particuology. 17, 136–144 (2014). https://doi.org/10.1016/j.partic.2013.09.004

Sunqing, Q., Junxiu, D., Guoxu, C.: Wear and friction behaviour of CaCO3 nanoparticles used as additives in lubricating oils. Lubr. Sci. 12, 205–212 (2000). https://doi.org/10.1002/ls.3010120207

Coles, J.M., Chang, D.P., Zauscher, S.: Molecular mechanisms of aqueous boundary lubrication by mucinous glycoproteins. Curr. Opin. Colloid Interface Sci. 15, 406–416 (2010). https://doi.org/10.1016/j.cocis.2010.07.002

Krim, J., Widom, A.: Damping of a crystal oscillator by an adsorbed monolayer and its relation to interfacial viscosity. Phys. Rev. B 38, 12184 (1988)

Bruschi, L., Mistura, G.: Measurement of the friction of thin films by means of a quartz microbalance in the presence of a finite vapor pressure. Phys. Rev. B 63, 235411 (2001)

Popov, V.L.: Coulomb’s law of friction. In: Contact Mechanics of Friction. p. 134 (2010)

Fajardo, O.Y., Bresme, F., Kornyshev, A.A., Urbakh, M.: Electrotunable friction with ionic liquid lubricants: how important is the molecular structure of the ions? https://doi.org/10.1021/acs.jpclett.5b01802

Fajardo, O.Y., Bresme, F., Kornyshev, A.A., Urbakh, M.: Electrotunable lubricity with ionic liquid nanoscale films. https://doi.org/10.1038/srep07698

Acknowledgements

This work was supported by National Science Foundation Award Number DMR1535082.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pardue, T.N., Acharya, B., Curtis, C.K. et al. A Tribological Study of γ-Fe2O3 Nanoparticles in Aqueous Suspension. Tribol Lett 66, 130 (2018). https://doi.org/10.1007/s11249-018-1083-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-018-1083-1