Abstract

We study scratching of a composite built from two widely different materials, a ductile and soft metal (Al) and a hard and brittle ceramic (Si). When scratching far away from the interface, the response of the pure elemental materials is monitored. A higher hardness and a lower friction coefficient are found for Si as compared to Al. The pile-up in Al is larger than in Si. When scratching along the interface, the composite responds approximately with the averaged behavior of the two pure materials. This applies to the forces as well as to the hardness and the friction coefficient. However, we observe a peculiar material flow, which can be described by a rotation around the scratch direction, inducing material mixing both in the groove bottom and in the pile-up; the harder Si expands on the groove bottom, while the softer Al expands in the pile-up region. When scratching across the interface, the material response switches on a length scale of the order of the contact radius. While the friction coefficient and the contact pressure switch from and to the values of the respective pure material, the behavior of the forces and areas is more complex. This is in particular due to the lateral pile-up that forms differently on the ductile metal and the amorphized Si parts.

Similar content being viewed by others

References

Elmadagli, M., Perry, T., Alpas, A.T.: A parametric study of the relationship between microstructure and wear resistance of Al-Si alloys. Wear 262, 79 (2007)

Chen, M., Meng-Burany, X., Perry, T.A., Alpas, A.T.: Micromechanisms and mechanics of ultra-mild wear in Al-Si alloys. Acta Mater. 56, 5605–5616 (2008)

Joseph, S., Kumar, S., Bhadram, V.S., Narayana, C.: Stress states in individual Si particles of a cast al-si alloy: micro-Raman analysis and microstructure based modeling. J. Alloys Compd. 625, 296–308 (2015)

Prashanth, K.G., Debalina, B., Wang, Z., Gostin, P.F., Gebert, A., Calin, M., Kühn, U., Kamaraj, M., Scudino, S., Eckert, J.: Tribological and corrosion properties of Al-12Si produced by selective laser melting. J. Mater. Res. 29, 2044–2054 (2014)

Mahato, A., Sachdev, A., Biswas, S.K.: Lubricated tribology of a eutectic aluminium-silicon alloy in the ultra-mild wear and mild wear regimes for long sliding times. ACS Appl. Mater. Interfaces 2, 2870–2879 (2010)

Dienwiebel, M., Pöhlmann, K., Scherge, M.: Origins of the wear resistance of AlSi cylinder bore surfaces studies by surface analytical tools. Tribol. Int. 40, 1597–1602 (2007)

Riahi, A.R., Perry, T., Alpas, A.T.: Scuffing resistances of Al-Si alloys: effects of etching condition, surface roughness and particle morphology. Mater. Sci. Eng. A 343, 76–81 (2003)

Das, S., Perry, T., Biswas, S.K.: Effect of surface etching on the lubricated sliding wear of an eutectic aluminium-silicon alloy. Tribol. Lett. 21, 193–204 (2006)

Mahato, A., Perry, T.A., Jayaram, V., Biswas, S.K.: Pressure and thermally induced stages of wear in dry sliding of a steel ball against an aluminium-silicon alloy flat. Wear 268, 1080–1090 (2010)

Elmadagli, M., Alpas, A.T.: Sliding wear of an Al-18.5 wt% Si alloy tested in an argon atmosphere and against DLC coated counterfaces. Wear 261, 823–834 (2006)

Alhafez, I.A., Brodyanski, A., Kopnarski, M., Urbassek, H.M.: Influence of tip geometry on nanoscratching. Tribol. Lett. 65, 26 (2017)

Kelchner, C.L., Plimpton, S.J., Hamilton, J.C.: Dislocation nucleation and defect structure during surface indentation. Phys. Rev. B 58, 11085–11088 (1998)

Li, J., Van Vliet, K.J., Zhu, T., Yip, S., Suresh, S.: Atomistic mechanisms governing elastic limit and incipient plasticity in crystals. Nature 418, 307–310 (2002)

Ziegenhain, G., Urbassek, H.M., Hartmaier, A.: Influence of crystal anisotropy on elastic deformation and onset of plasticity in nanoindentation: a simulational study. J. Appl. Phys. 107, 061807 (2010)

Hagelaar, J.H.A., Bitzek, E., Flipse, C.F.J., Gumbsch, P.: Atomistic simulations of the formation and destruction of nanoindentation contacts in tungsten. Phys. Rev. B 73, 045425 (2006)

Gao, Y., Ruestes, C.J., Urbassek, H.M.: Nanoindentation and nanoscratching of iron: atomistic simulation of dislocation generation and reactions. Comput. Mater. Sci. 90, 232–240 (2014)

Gao, Y., Brodyanski, A., Kopnarski, M., Urbassek, H.M.: Nanoscratching of iron: a molecular dynamics study of the influence of surface orientation and scratching direction. Comput. Mater. Sci. 103, 77–89 (2015)

Alhafez, I.A., Ruestes, C.J., Gao, Y., Urbassek, H.M.: Nanoindentation of hcp metals: a comparative simulation study of the evolution of dislocation networks. Nanotechnology 27, 045706 (2016)

Goel, S., Faisal, N.H., Luo, X., Yan, J., Agrawal, A.: Nanoindentation of polysilicon and single crystal silicon: molecular dynamics simulation and experimental validation. J. Phys. D 47, 275304 (2014)

Zhang, Z., Stukowski, A., Urbassek, H.M.: Interplay of dislocation-based plasticity and phase transformation during Si nanoindentation. Comput. Mater. Sci. 119, 82–89 (2016)

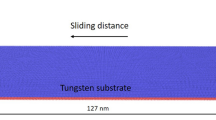

Zhang, Z., Urbassek, H.M.: Indentation into an Al-Si composite: enhanced dislocation mobility at interface. J. Mater. Sci. 53, 799–813 (2018)

Fang, T.-H., Jia-Hung, W.: Molecular dynamics simulations on nanoindentation mechanisms of multilayered films. Comput. Mater. Sci. 43, 785–790 (2008)

Shen, Y.-L., Blada, C.B., Williams, J.J., Chawla, N.: Cyclic indentation behavior of metal-ceramic nanolayered composites. Mater. Sci. Eng. A 557, 119–125 (2012)

Jun, S., Lee, Y., Kim, S.Y., Im, S.: Large-scale molecular dynamics simulations of Al(111) nanoscratching. Nanotechnology 15, 1169–1174 (2004)

Alhafez, I.A., Urbassek, H.M.: Scratching of hcp metals: a molecular-dynamics study. Comput. Mater. Sci. 113, 187–197 (2016)

Zarudi, I., Cheong, W.C.D., Zou, J., Zhang, L.C.: Atomistic structure of monocrystalline silicon in surface nano-modification. Nanotechnology 15, 104 (2004)

Mylvaganam, K., Zhang, L.C.: Nanotwinning in monocrystalline silicon upon nanoscratching. Scr. Mater. 65, 214–216 (2011)

Goel, S., Kovalchenko, A., Stukowski, A., Cross, G.: Influence of microstructure on the cutting behaviour of silicon. Acta Mater. 105, 464–478 (2016)

Noreyan, A., Qi, Y., Stoilov, V.: Critical shear stresses at aluminum-silicon interfaces. Acta Mater. 56, 3461–3469 (2008)

Zhang, Z., Urbassek, H.M.: Dislocations penetrating an Al-Si interface. AIP Adv. 7, 125119 (2017)

Saidi, P., Frolov, T., Hoyt, J.J., Asta, M.: An angular embedded atom method interatomic potential for the aluminum-silicon system. Model. Simul. Mater. Sci. Eng. 22, 055010 (2014)

Mendelev, M.I., Kramer, M.J., Becker, C.A., Asta, M.: Analysis of semi-empirical interatomic potentials appropriate for simulation of crystalline and liquid Al and Cu. Philos. Mag. 88, 1723–1750 (2008)

Stillinger, F.H., Weber, T.A.: Computer simulation of local order in condensed phases of Si. Phys. Rev. B 31, 5262–5271 (1985)

Gao, Y., Ruestes, C.J., Tramontina, D.R., Urbassek, H.M.: Comparative simulation study of the structure of the plastic zone produced by nanoindentation. J. Mech. Phys. Sol. 75, 58–75 (2015)

Godet, J., Pizzagalli, L., Brochard, S., Beauchamp, P.: Theoretical study of dislocation nucleation from simple surface defects in semiconductors. Phys. Rev. B 70, 054109 (2004)

Chrobak, D., Tymiak, N., Beaber, A., Ugurlu, O., Gerberich, W.W., Nowak, R.: Deconfinement leads to changes in the nanoscale plasticity of silicon. Nat. Nanotechnol. 6, 480 (2011)

Hale, L.M., Zhang, D.-B., Zhou, X., Zimmerman, J.A., Moody, N.R., Dumitrica, T., Ballarini, R., Gerberich, W.W.: Dislocation morphology and nucleation within compressed Si nanospheres: a molecular dynamics study. Comput. Mater. Sci. 54, 280–286 (2012)

Zhang, Z., Urbassek, H.M.: Comparative study of interatomic interaction potentials for describing indentation into Si using molecular dynamics simulation. Appl. Mech. Mater. 869, 3–8 (2017)

Zhang, Z., Urbassek, H.M.: Dislocation-based strengthening mechanisms in metal-matrix nanocomposites: a molecular dynamics study of the influence of reinforcement shape in the Al-Si system. Comput. Mater. Sci. 145, 109–115 (2018)

Alcalá, J., Dalmau, R., Franke, O., Biener, M., Biener, J., Hodge, A.: Planar defect nucleation and annihilation mechanisms in nanocontact plasticity of metal surfaces. Phys. Rev. Lett. 109, 075502 (2012)

Ruestes, C.J., Bringa, E.M., Gao, Y., Urbassek, H.M.: Molecular dynamics modeling of nanoindentation. In: Tiwari, A., Natarajan, S. (eds.) Applied Nanoindentation in Advanced Materials, pp. 313–345. Wiley, Chichester (2017)

Plimpton, S.: Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 117, 1–19 (1995). http://lammps.sandia.gov/

Stukowski, A.: Visualization and analysis of atomistic simulation data with OVITO–the open visualization tool. Model. Simul. Mater. Sci. Eng. 18, 015012 (2010). http://www.ovito.org/

Stukowski, A., Bulatov, V.V., Arsenlis, A.: Automated identification and indexing of dislocations in crystal interfaces. Model. Simul. Mater. Sci. Eng. 20, 085007 (2012)

Stukowski, A.: Structure identification methods for atomistic simulations of crystalline materials. Model. Simul. Mater. Sci. Eng. 20, 045021 (2012)

Stukowski, A., Arsenlis, A.: On the elastic-plastic decomposition of crystal deformation at the atomic scale. Model. Simul. Mater. Sci. Eng. 20, 035012 (2012)

Honeycutt, J.D., Andersen, H.C.: Molecular dynamics study of melting and freezing of small Lennard-Jones clusters. J. Phys. Chem. 91, 4950–4963 (1987)

Clarke, A.S., Jonsson, H.: Structural changes accompanying densification of random hard-sphere packings. Phys. Rev. B 47, 3975 (1993)

Maras, E., Trushin, O., Stukowski, A., Ala-Nissila, T., Jonsson, H.: Global transition path search for dislocation formation in Ge on Si(001). Comput. Phys. Commun. 205, 13–21 (2016)

Alhafez, I.A., Ruestes, C.J., Urbassek, H.M.: Size of the plastic zone produced by nanoscratching. Tribol. Lett. 66, 20 (2018)

Moore, A.J.W., Tegart, W.J.M.: Relation between friction and hardness. Proc. R. Soc. Lond. A 212, 452–458 (1952)

Acknowledgements

Simulations were performed at the High Performance Cluster Elwetritsch (RHRK, TU Kaiserslautern, Germany). We acknowledge the financial support of the Deutsche Forschungsgemeinschaft via the IRTG 2057 and the SFB 926.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, Z., Alabd Alhafez, I. & Urbassek, H.M. Scratching an Al/Si Interface: Molecular Dynamics Study of a Composite Material. Tribol Lett 66, 86 (2018). https://doi.org/10.1007/s11249-018-1038-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-018-1038-6