Abstract

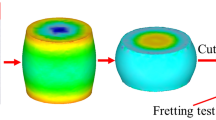

Engineering components can be subjected to normal and/or rotational fretting wear with contacts that are intermittently exposed to the atmosphere. Exposure to the environment may lead to the alteration at the contact due to the changing role of third body particles such as hard oxides which can result in abrasion. The abrasion due to hard oxide particles differs for the closed contact and intermittently opened contact. In the former scenario, the oxides are compacted into tribo-film, while in the latter case they remain loose, leading to bigger role of abrasion. Standard fretting test setup employed to estimate the fretting wear characteristic operates with a constant load such that the contact remains closed between the counter surfaces and does not simulate the opening and closing of the contacts as observed in certain applications. The forceful interruptions to the experiments to simulate open and close condition of the contact require considerable amount of time and effort. In this paper, an accelerated test procedure is proposed and investigated to capture the effect of intermittent opening of the contact without stopping the experiments. A test rig is designed to simulate the opening and closing conditions, and tests were performed with abrasive diamond-like particles. Friction and wear results are compared with those of intermittently contact opening conditions along with operating wear mechanisms. Scanning electron microscope analysis showed that the wear mechanism observed in the case of fretting with intermittent opening of contact is similar to that of fretting with diamond-like abrasives at the contact.

Similar content being viewed by others

References

Iwabuchi, A.: The role of oxide particles in the fretting wear of mild steel. Wear 151, 301–311 (1991)

Suh, N.P., Sin, H.C.: The genesis of friction. Wear 69, 91–114 (1981)

Sherrington, I., Hayhurst, P.: Simultaneous observation of the evaluation of debris density and friction coefficient in dry sliding steel contacts. Wear 249, 182–187 (2001)

Saber, D., Emam, I.S., Abdel-Karim, R.: High temperature cyclic oxidation of Ni based super alloys at different temperatures in air. J. Alloys Compd. 719, 133–141 (2017)

Xin, L., Yang, B.B., Wang, Z.H., Li, J., Lu, Y.H., Shoji, T.: Microstructural evolution of subsurface on Inconel 690TT alloy subjected to fretting wear at elevated temperature. Mater. Des. 104, 152–161 (2016)

Soria, S.R., Tolley, A., Yawny, A.: A study of debris and wear damage resulting from fretting of Incoloy 800 steam generator tubes against AISI Type 304 stainless steel. Wear 368–369, 219–229 (2016)

Jin, X., Sun, W., Shipway, P.H.: The role of geometry changes and debris formation associated with wear on the temperature field in fretting contacts. Tribol. Int. 102, 392–406 (2016)

Jin, X., Shipway, P.H., Sun, W.: The role of temperature and frequency on fretting wear of a like-on-like stainless steel contact. Tribol. Lett. 65, 77 (2017). doi:10.1007/s11249-017-0858-0

Soderberg, S., Nikoonezhad, S., Salama, K., Vingsbo, S.: Accelerated fretting wear testing using ultrasonics. Ultrasonics 24, 348–353 (1986)

Malucci R.D.: Accelerated testing of tin plated copper alloy contacts. In: Proceedings of the Forty-Third IEEE Holm Conference (1997)

Kiely, J., Peng, W., Hsia, Y.-T.: Accelerated wear testing of head-disc interfaces. Tribol. Int. 38, 652–656 (2005)

Beake, B.D., Liskiewicz, T.W., Pickford, N.J., Smith, J.F.: Accelerated nano-fretting testing of Si(1 0 0). Tribol. Int. 46, 114–118 (2012)

Okamoto, M., Jibiki, T., Ito, S., Motoda, T.: Role of cross-grooved type texturing in acceleration of initial running-in under lubricated fretting. Tribol. Int. 100, 126–131 (2016)

Trezona, R.I., Allsopp, D.N., Hutchings, I.M.: Transitions between two-body and three-body abrasive wear: influence of test conditions in the microscale abrasive wear test. Wear 229–229, 205–214 (1999)

Kassman, A., Jacobson, S., Erickson, L., Hedenqvist, P., Olsson, M.: A new test method for the intrinsic abrasion resistance of thin coatings. Surf. Coat. Technol. 50, 75–84 (1991)

Staia, M.H., Enriquez, C., Puchi, E.S.: Influence of the heat treatment on the abrasive wear resistance of electroless Ni–P. Surf. Coat. Technol. 94–95, 543–548 (1997)

Kesavan, D., Done, V., Sridhar, M.R., Billig, R., Nélias, D.: High temperature fretting wear prediction of exhaust valve material. Tribol. Int. 100, 280–286 (2016)

Gallego, L., Nélias, D., Jacq, C.: A comprehensive method to predict wear and to define the optimum geometry of fretting surfaces. J. Tribol. 128(3), 476–485 (2006)

Gallego, L., Nélias, D.: A modeling of fretting wear under gross slip and partial slip conditions. J. Tribol. 129(3), 528–535 (2007)

Gallego, L., Fulleringer, B., Deyber, S., Nelias, D.: Multiscale computation of fretting wear at the blade/disk interface. Tribol. Int. 43, 708–718 (2010)

Antaluca, E., Nélias, D.: Contact fatigue analysis of a dented surface in a dry elastic–plastic circular point contact. Tribol. Lett. 29, 139–153 (2008)

Fouvry, S., Kapsa, P., Vincent, L.: Quantification of fretting damage. Wear 200, 186–205 (1996)

Done, V., Kesavan, D., Krishna, R.M., Chaise, T., Nelias, D.: Semi analytical fretting wear simulation including wear debris. Tribol. Int. 109, 1–9 (2017)

Inman, I.A., Datta, P.S.: Studies of high temperature sliding wear of metallic dissimilar interfaces IV: nimonic 80A versus Incoloy 800HT. Tribol. Int. 44, 1902–1919 (2011)

Prelas, M.A., Popovici, G., Bigelow, L.K.: Handbook of Industrial Diamonds and Diamond Films, pp. 59–78. Marcel Dekker INC, New York (1998)

Suh, N.P.: The delamination theory of wear. Wear 25, 111–124 (1973)

Fouvry, S., Arnaud, P., Mignot, A., Neubauer, P.: Contact size, frequency and cyclic normal force effects on Ti–6Al–4 V fretting wear processes: an approach combining friction power and contact oxygenation. Tribol. Int. 113, 460–473 (2017)

Kato, H., Komai, K.: Tribofilm formation and mild wear by tribo-sintering of nanometer-sized oxide particles on rubbing steel surfaces. Wear 262, 1–2 (2007)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Done, V., Kesavan, D., Huffman, M. et al. Accelerated Fretting Wear Tests for Contacts Exposed to Atmosphere. Tribol Lett 65, 153 (2017). https://doi.org/10.1007/s11249-017-0940-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-017-0940-7