Abstract

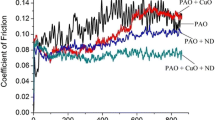

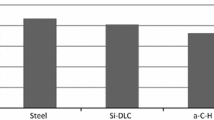

Ni nanoparticles (with average diameter 7 nm) capped with oleylamine and oleic acid were added to a DLC/DIOS solid–liquid synergetic lubricating system. The tribological behavior rubbed with steel balls in three lubricating regimes (boundary, mixed and elasto-hydrodynamic lubrication) has been systematically studied by surface analyses techniques such as SEM, EDX and XPS. It was found that, in all the lubricating regimes, the system’s lubricating performance was substantially improved because of the addition of the Ni nanoparticles. For all the lubrication regimes, the COF decreased by 10.3–19.1%. In the boundary lubrication regime, the wear rate of DLC could be decreased by 50%. Ni nanocores facilitate the adequate oxidation of the steel surface and the transformation of C=C (sp2) to C–C (sp3) of the DLC sliding surface. The tribo-film containing ferrous oxides, Ni and its oxides, presents low shearing strength and good cohesion to the DLC coating, which greatly improves the lubricating behaviors of the DLC/DIOS solid–liquid synergetic system. In the elasto-hydrodynamic lubrication regime, the Ni nanoparticles cause the occurrence of obstructed or plug flow in the oil films, which in turn reduces friction by reducing the layers of lubricant molecules to slide on each other.

Similar content being viewed by others

References

Ronkainen, H., Varjus, S., Holmberg, K.: Friction and wear properties in dry, water- and oil-lubricated DLC against alumina and DLC against steel contacts. Wear 222, 120–128 (1998)

Vengudusamy, B., Mui, R.A., Lamb, G.D., Green, J.H., Spikes, H.A.: Friction properties of DLC/DLC contacts in base oil. Tribol. Int. 44, 922–932 (2011)

Ren, S., Zheng, S., Pu, J., Lu, Z., Zhang, G.: Study of tribological mechanisms of carbon-based coatings in antiwear additive containing lubricants under high temperature. RSC Adv. 5, 66426–66437 (2015)

Grischke, M., Hieke, A., Morgenweck, F., Dimigen, H.: Variation of the wettability of DLC-coatings by network modification using silicon and oxygen. Diam. Relat. Mater. 7, 454–458 (1998)

Kalin, M., Vižintin, J., Barriga, J., Vercammen, K., VanAcker, K., Arnšek, A.: The effect of doping elements and oil additives on the tribological performance of boundary-lubricated DLC/DLC contacts. Tribol. Lett. 17, 679–688 (2004)

Neville, A., Morina, A., Haque, T., Voong, M.: Compatibility between tribological surfaces and lubricant additives—how friction and wear reduction can be controlled by surface/lube synergies. Tribol. Int. 40(10–12), 1680–1695 (2007)

Keunecke, M., Bewilogua, K., Becker, J., Gies, A., Grischke, M.: CrC/a-C: H coatings for highly loaded, low friction applications under formulated oil lubrication. Surf. Coat. Technol. 207, 270–278 (2012)

Kalin, M., Roman, E., Ožbolt, L., Vižintin, J.: Metal-doped (Ti, WC) diamond-like-carbon coatings: reactions with extreme-pressure oil additives under tribological and static conditions. Thin Solid Films 518, 4336–4344 (2010)

Vengudusamy, B., Green, J.H., Lamb, G.D., Spikes, H.A.: Behaviour of MoDTC in DLC/DLC and DLC/steel contacts. Tribol. Int. 54, 68–76 (2012)

Holmberg, K., Andersson, P., Erdemir, A.: Global energy consumption due to friction in passenger cars. Tribol. Int. 47, 221–234 (2012)

Nosonovsky, M., Bhushan, B.: Lotus versus rose: biomimetic surface effects. Green Energy Technol. 49, 25–40 (2012)

Kalin, M., Kogovšek, J., Remškar, M.: Nanoparticles as novel lubricating additives in a green, physically based lubrication technology for DLC coatings. Wear 303, 480–485 (2013)

Kogovšek, J., Remškar, M., Kalin, M.: Lubrication of DLC-coated surfaces with MoS2 nanotubes in all lubrication regimes: surface roughness and running-in effects. Wear 303, 361–370 (2013)

Ghaednia, H., Babaei, H., Jackson, R.L., Bozack, M.J., Khodadadi, J.M.: The effect of nanoparticles on thin film elasto-hydrodynamic lubrication. Appl. Phys. Lett. 103, 263111 (2013)

Zhao, Y., Zhang, Z., Dang, H.: A novel solution route for preparing indium nanoparticles. J. Phys. Chem. B. 107(31), 7574–7576 (2003)

Lahouij, I., Dassenoy, F., Knoop, L., Martin, J.M., Vacher, B.: In situ TEM observation of the behavior of an individual fullerene-like MoS2 nanoparticle in a dynamic contact. Tribol. Lett. 42(2), 133–140 (2011)

Tang, Z., Li, S.: A review of recent developments of friction modifiers for liquid lubricants (2007-present). Curr. Opin. Solid State Mater. Sci. 18, 119–139 (2014)

Khond, V.W., Kriplani, V.M.: Effect of nanofluid additives on performances and emissions of emulsified diesel and biodiesel fueled stationary CI engine: a comprehensive review. Renew. Sustain. Energy Rev. 59, 1338–1348 (2016)

Chen, Y., Zhang, Y., Zhang, S., Laigui, Yu., Zhang, P., Zhang, Z.: Preparation of nickel-based nanolubricants via a facile in situ one-step route and investigation of their tribological properties. Tribol. Lett. 51, 73–83 (2013)

Li, F., Zhang, S., Kong, J., Zhang, Y., Zhang, W.: Multilayer DLC coatings via alternating bias during magnetron sputtering. Thin Solid Films 519, 4910–4916 (2011)

Hamrock, B.J., Dowson, D.: Isothermal elastohydrodynamic lubrication of point contacts., Part-III, fully flooded results. J. Lubr. Technol. 99(2), 264–276 (1977)

Nishikawa, H., Kaneta, M.: Stribeck fricition curve in point EHL contact. Tribol. Online 1, 1–4 (2006)

Tallian, T.E.: On competing failure modes in rolling contact. ASLE Trans. 10, 418–439 (1967)

Cai, M., Liang, Y., Zhou, F., Liu, W.: Tribological properties ofnovel imidazolium ionic liquids bearing benzotriazole group as the antiwear/anticorrosion additive in poly(ethylene glycol) and polyurea grease for steel/steel contacts. ACS Appl. Mater. Interfaces. 3, 4580–4592 (2011)

Burghardt, G., Wächter, F., Jacobs, G., Hentschke, C.: Influence of run-in procedures and thermal surface treatment on the anti-wear performance of additive-free lubricant oils in rolling bearings. Wear 328–329, 309–317 (2015)

Acknowledgements

The authors acknowledge the financial support provided by the Ministry of Science and Technology of China (Project of ‘‘973” plan; Grant No. 2013CB632303), National Natural Science Foundation of China (51275154, 51405132), Plan for Young Scientific Innovation Talent of Henan Province (154100510018), Innovation Scientists and Technicians Troop Construction Projects of Henan Province (C20150011), Natural Science Foundation of Henan Province (14A150006).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, Y., Xin, L., Zhang, Y. et al. The Effect of Ni Nanoparticles on the Lubrication of a DLC-Based Solid–Liquid Synergetic System in All Lubrication Regimes. Tribol Lett 65, 31 (2017). https://doi.org/10.1007/s11249-017-0814-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-017-0814-z