Abstract

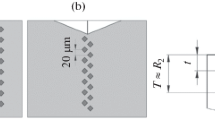

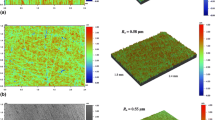

In order to reveal fundamental tribological mechanisms in polymer/steel sliding pairs, the pin-on-flat configuration of classical macroscopic tribotests was transferred into a high-resolution tribometer designed for scratch tests. Experiments were performed with a polyetheretherketone (PEEK) pin sliding on a steel disk in straight unidirectional movement mode. The surface morphology was monitored by interrupting the tests every 10,000 sliding strokes. The evolving surface morphology of PEEK was correlated with the transfer layer formed on steel counter surface. Scratching grooves in the PEEK surface were induced by asperities at the counter steel surface covered with transfer layers. Transfer layers were composed of lumpy polymer material accompanied by fine wear debris in areas of lower roughness. These smooth areas limit the penetration of large asperities and distinguish the scratching mechanism in macroscopic sliding from typical single-asperity scratching tests. The results reveal the mechanisms leading to inhomogeneity in the transfer layers as consequence of the asperity distribution.

Similar content being viewed by others

References

Xiong, D., Xiong, L., Liu, L.: Preparation and tribological properties of polyetheretherketone composites. J. Biomed. Mater. Res. B Appl. Biomater. 93B(2), 492–496 (2010). doi:10.1002/jbm.b.31607

Li, D., Xie, Y., Li, W., You, Y., Deng, X.: Tribological and mechanical behaviors of polyamide 6/glass fiber composite filled with various solid lubricants. Sci. World J. 2013, 9 (2013). doi:10.1155/2013/320837

Yu, L., Yang, S., Liu, W., Xue, Q.: An investigation of the friction and wear behaviors of polyphenylene sulfide filled with solid lubricants. Polym. Eng. Sci. 40(8), 1825–1832 (2000). doi:10.1002/pen.11314

Abdelbary, A.: Wear of Polymers and Composites. Woodhead Publishing, Cambridge (2015)

Aldousiri, B., Shalwan, A., Chin, C.W.: A review on tribological behaviour of polymeric composites and future reinforcements. Adv. Mater. Sci. Eng. 2013, 8 (2013). doi:10.1155/2013/645923

Onodera, T., Park, M., Souma, K., Ozawa, N., Kubo, M.: Transfer-film formation mechanism of polytetrafluoroethylene: a computational chemistry approach. J. Phys. Chem. C 117(20), 10464–10472 (2013). doi:10.1021/jp400515j

Nunez, E.E., Polycarpou, A.A.: The effect of surface roughness on the transfer of polymer films under unlubricated testing conditions. Wear 326–327, 74–83 (2015). doi:10.1016/j.wear.2014.12.049

Rzatki, F.D., Barboza, D.V.D., Schroeder, R.M., Barra, GMdO, Binder, C., Klein, A.N., de Mello, J.D.B.: Effect of surface finishing, temperature and chemical ageing on the tribological behaviour of a polyether ether ketone composite/52100 pair. Wear 332–333, 844–854 (2015). doi:10.1016/j.wear.2014.12.035

Bahadur, S., Schwartz, C.J.: The influence of nanoparticle fillers in polymer matrices on the formation and stability of transfer film during wear. In: Friedrich, K., Schlarb, A.K. (eds.) Tribology and Interface Engineering Series, vol. 55, pp. 17–34. Elsevier, Amsterdam (2008)

Windarta, M., Sudin, M.B., Baharom, M.B.: Prediction of contact temperature on interaction between rail and wheel materials using Pin-on-Disc method. J. Appl. Sci. 12, 2424–2429 (2012)

Pei, X., Friedrich, K.: Sliding wear properties of PEEK, PBI and PPP. Wear 274, 452–455 (2012). doi:10.1016/j.wear.2011.09.009

Kónya, L., Váradi, K., Friedrich, K.: Finite element modelling of wear process of a PEEK-steel sliding pair at elevated temperature. Period. Polytech. Mech. Eng. 49(1), 25–38 (2005)

Rodriguez, V., Sukumaran, J., Perez, Y., De Baets, P., Ando, M.: Tribological behaviour of the low and high viscosity PEEK against steel using different contact pressures. Int. J. Sustain. Constr. Des. 4(2), 1–10 (2013)

Rodriguez Fereira, V., Sukumaran, J., Perez Delgado, Y., De Baets, P., Igartua, A., Fernandez, B., Schlarb, A.K.: Proceedings of LUBMAT 2012-Lubrication, Maintenance and Tribotechnology. pp. 145–149 (2012)

Chang, L., Friedrich, K., Zhang, G.: New insights into wear behavior of high performance polymers. In: Proceedings of the 14th IFToMM World Congress (14th-3), 688–694 (2015). doi:10.6567/IFToMM.14TH.WC.OS18.025

Zhang, G., Liao, H., Li, H., Mateus, C., Bordes, J.M., Coddet, C.: On dry sliding friction and wear behaviour of PEEK and PEEK/SiC-composite coatings. Wear 260(6), 594–600 (2006). doi:10.1016/j.wear.2005.03.017

Blau, P.J., Devore, C.E.: Interpretations of the sliding friction break-in curves of alumina-aluminum couples. Wear 129(1), 81–92 (1989). doi:10.1016/0043-1648(89)90281-0

Zalisz, Z., Vroegop, P.H., Bosma, R.: A running-in model for the reciprocating sliding of Nylon 6.6 against stainless steel. Wear 121(1), 71–93 (1988). doi:10.1016/0043-1648(88)90032-4

Blau, P.J.: Friction Science and Technology: From Concepts to Applications. CRC Press, Taylor & Francis Group, Boca Raton (2009)

Kato, K.: Wear in relation to friction—a review. Wear 241(2), 151–157 (2000). doi:10.1016/S0043-1648(00)00382-3

Adachi, K., Kato, K., Takizawa, R.: Smoothing effect of the third body compaction on alumina surface in sliding contact. In: Dowson, D., Taylor, C.M., Childs, T.H.C., Dalmaz, G., Berthier, Y., Flamand, L., Georges, J.-M., Lubrecht, A.A. (eds.) Tribology Series, vol. 31, pp. 585–596. Elsevier, Amsterdam (1996)

Jeng, Y.-R., Lin, Z.-W., Shyu, S.-H.: Changes of surface topography during running-in process. J. Tribol. 126(3), 620–625 (2004). doi:10.1115/1.1759344

Pei, X.-Q., Bennewitz, R., Busse, M., Schlarb, A.K.: Effects of single asperity geometry on friction and wear of PEEK. Wear 304(1–2), 109–117 (2013). doi:10.1016/j.wear.2013.04.032

Briscoe, B.J., Sinha, S.K.: Wear of polymers. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 216(6), 401–413 (2002). doi:10.1243/135065002762355325

Biswas, S.K., Vijayan, K.: Friction and wear of PTFE—a review. Wear 158(1–2), 193–211 (1992). doi:10.1016/0043-1648(92)90039-b

Samyn, P., De Baets, P., Van Craenenbroeck, J., Verpoort, F., Schoukens, G.: Thermal transitions in polyimide transfer under sliding against steel, investigated by Raman spectroscopy and thermal analysis. J. Appl. Polym. Sci. 101(3), 1407–1425 (2006). doi:10.1002/app.22395

Zmitrowicz, A.: Wear debris: a review of properties and constitutive models. J. Theor. Appl. Mech. 43(1), 3–35 (2005)

Tzanakis, I., Conte, M., Hadfield, M., Stolarski, T.A.: Experimental and analytical thermal study of PTFE composite sliding against high carbon steel as a function of the surface roughness, sliding velocity and applied load. Wear 303(1–2), 154–168 (2013). doi:10.1016/j.wear.2013.02.011

El-Tayeb, N.S.M., Yousif, B.F.: Evaluation of glass fiber reinforced polyester composite for multi-pass abrasive wear applications. Wear 262(9–10), 1140–1151 (2007). doi:10.1016/j.wear.2006.11.015

Friedrich, K., Sue, H.J., Liu, P., Almajid, A.A.: Scratch resistance of high performance polymers. Tribol. Int. 44(9), 1032–1046 (2011). doi:10.1016/j.triboint.2011.04.008

Acknowledgments

The authors acknowledge financial support of the German Research Foundation (Deutsche Forschungsgemeinschaft) and thank Eduard Arzt for the continuous support of this project. The authors are also grateful to Karl-Peter Schmitt and Birgit Heiland for their help in tribological tests and SEM observation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pei, XQ., Lin, LY., Schlarb, A.K. et al. Novel Experiments Reveal Scratching and Transfer Film Mechanisms in the Sliding of the PEEK/Steel Tribosystem. Tribol Lett 63, 40 (2016). https://doi.org/10.1007/s11249-016-0732-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-016-0732-5