Abstract

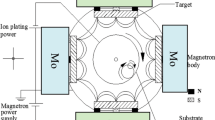

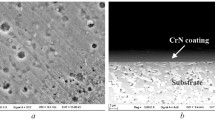

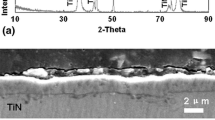

CrB2 and Cr–B–N films were deposited by magnetron sputtering of CrB2 target in an argon atmosphere or in a gaseous mixture of argon and nitrogen. The films were characterized in terms of their adhesion strength, sliding, and impact wear resistance. Crack resistance of the films was evaluated by micro-indentations. The adhesion strength was studied by means of scratch testing. The wear tests were performed under different loads against chromium steel and WC–Co counterpart materials. In order to determine the film fatigue toughness, dynamic impact tests were carried out. The indentations, scars, wear tracks, and impact cavities on the film surface were examined using optical profilometry, as well as optical and scanning electron microscopy. Comparison of lifetimes of CrB2 and Cr–B–N-coated cemented carbide mills in dry milling of D2 high-chromium steel was also performed. The obtained results show that the CrB2 film has poor adhesion, low fracture toughness, and rapidly fails during sliding and dynamic impact tests. In contrast, the Cr–B–N films with nitrogen content between 7 and 11 at.% exhibited superior adhesion strength (critical load \(L_{{{\text{c}}_{2} }}\) = 70–90 N), good tribological properties (friction coefficient against WC–Co <0.4 and wear rate <2×10−6 mm3 N−1 m−1), and reduced impact wear. The lifetime of mills coated with Cr–B–N films was 1.3 and 2.0 times longer as compared to the tools coated with TiN and CrB2 films and uncoated WC–Co tools, respectively.

Similar content being viewed by others

References

Hogmark, S., Jacobson, S., Larsson, M.: Design and evaluation of tribological coatings. Wear 246, 20–33 (2000)

Padture, N.P., Gell, M., Jordan, E.H.: Thermal barrier coatings for gas-turbine engine applications. Science 296, 280–284 (2002)

Holzschuh, H.: Deposition of Ti–B–N (single and multilayer) and Zr–B–N coatings by chemical vapor deposition techniques on cutting tools. Thin Solid Films 469–470, 92–98 (2004)

Wallgram, W., Schlenkofer, U.: Synthesis, structure, and behavior of a new CVD TiB2 coating with extraordinary properties for high performance applications. In: Proceedings of 17th Plansee Seminar (2009)

Muller, K.B.: Deposition of hard films on hot-working steel dies for aluminium. J. Mater. Process. Technol. 130–131, 432–437 (2002)

Mitterer, C., Holler, F., Reitberger, D., Badisch, E., Stoiber, M., Lugmair, C., Nöbauer, R., Müller, Th, Kullmer, R.: Industrial applications of PACVD hard coatings. Surf. Coat. Technol. 163–164, 716–722 (2003)

Kiryukhantsev-Korneev, F.V., Shirmanov, N.A., Sheveiko, A.N., Levashov, E.A., Petrzhik, M.I., Shtanskii, D.V.: Nanostructural wear resistant coatings produced on metal cutting tools by electric arc evaporation and magnetronic sputtering. Russ. Eng. Res. 30, 909–919 (2010)

Shtansky, D.V., Kiryukhantsev-Korneev, PhV, Bashkova, I.A., Sheveiko, A.N., Levashov, E.A.: Multicomponent nanostructured films for various tribological applications. Int. J. Refract. Met. Hard Mater. 28, 32–39 (2010)

Shtansky, D.V., Sheveiko, A.N., Petrzhik, M.I., Kiryukhanntsev-Korneev, F.V., Levashov, E.A., Leyland, A., Yerokhin, A.L., Matthews, A.: Hard tribological Ti–B–N, Ti–Cr–B–N, Ti–Si–B–N and Ti–Al–Si–B–N coatings. Surf. Coat. Technol. 200, 208–212 (2005)

Dearnley, P.A., Schellewald, M., Dahm, K.L.: Characterisation and wear response of metal-boride coated WC–Co. Wear 259, 861–869 (2005)

Louro, C., Lamni, R., Levy, F.: W–B–N sputter-deposited thin films for mechanical application. Surf. Coat. Technol. 200, 753–759 (2005)

Jayaraman, S., Gerbi, J.E., Yang, Y., Kim, D.Y., Chatterjee, A., Bellon, P., Girolami, G.S., Chevalier, J.P., Abelson, J.R.: HfB2 and Hf–B–N hard coatings by chemical vapor deposition. Surf. Coat. Technol. 200, 6629–6633 (2006)

Gorishnyy, T.Z., Mihut, D., Rohde, S.L., Aouadi, S.M.: Physical and mechanical properties of reactively sputtered chromium boron nitride thin films. Thin Solid Films 445, 96–104 (2003)

Neidhardt, J., O’Sullivan, M., Reiter, A.E., Rechberger, W., Grogger, W., Mitterer, C.: Structure–property–performance relations of high-rate reactive arc-evaporated Ti–B–N nanocomposite coatings. Surf. Coat. Technol. 201, 2553–2559 (2006)

Kiryukhantsev-Korneev, PhV, Pierson, J.F., Petrzhik, M.I., Alnot, M., Levashov, E.A., Shtansky, D.V.: Effect of nitrogen partial pressure on the structure, physical and mechanical properties of CrB2 and Cr–B–N films. Thin Solid Films 517, 2675–2680 (2009)

He, J.L., Miyake, S., Setsuhara, Y., Shimizu, I., Suzuki, M., Numata, K., Sait, H.: Improved anti-wear performance of nanostructured titanium boron nitride coatings. Wear 249, 498–502 (2001)

Lin, J., Moore, J.J., Moerbe, W.C., Pinkas, M., Mishra, B., Doll, G.L., Sproul, W.D.: Structure and properties of selected (Cr–Al–N, TiC–C, Cr–B–N) nanostructured tribological coatings. Int. J. Refract. Met. Hard Mater. 28, 2–14 (2010)

Chapusot, V., Pierson, J.F., Lapostolle, F., Billard, A.: Arc-evaporated nanocomposite zirconium-based boronitride coatings. Mater. Chem. Phys. 114, 780–784 (2009)

Sakamaoto, Y., Nose, M., Mae, T., Honbo, E., Zhou, M., Nogi, K.: Structure and properties of Cr–B, Cr–B–N and multilayer Cr–B/Cr–B–N thin films prepared by r.f.-sputtering. Surf. Coat. Technol. 174–175, 444–449 (2003)

Polychronopoulou, K., Baker, M.A., Rebholz, C., Neidhardt, J., O’Sullivan, M., Reiter, A.E., Kanakis, K., Leyland, A., Matthews, A., Mitterer, C.: The nanostructure, wear and corrosion performance of arc-evaporated CrB x N y nanocomposite coatings. Surf. Coat. Technol. 204, 246–255 (2009)

Mallia, B., Stuber, M., Dearnley, P.A.: Character and chemical-wear response of high alloy austenitic stainless steel (Ortron 90) surface engineered with magnetron sputtered Cr–B–N ternary alloy coatings. Thin Solid Films 549, 216–223 (2013)

Budna, K.P., Mayrhofer, P.H., Neidhardt, J., Hegedus, E., Kovacs, I., Toth, L., Pecz, B., Mitterer, C.: Effect of nitrogen-incorporation on structure, properties and performance of magnetron sputtered CrB2. Surf. Coat. Technol. 202, 3088–3093 (2008)

Cheng, C.-H., Lee, J.W., Ho, L.W., Chen, H.-W., Chan, Y-Ch., Duh, J.-G.: Microstructure and mechanical property evaluation of pulsed DC magnetron sputtered Cr–B and Cr–B–N films. Surf. Coat. Technol. 206, 1711–1719 (2011)

Leyland, A., Matthews, A.: On the significance of the H/E ratio in wear control: a nanocomposite coating approach to optimised tribological behaviour. Wear 246, 1–11 (2000)

Shtansky, D.V., Kulinich, S.A., Levashov, E.A., Sheveiko, A.N., Kiriuhancev, F.V., Moore, J.J.: Localized deformation of multicomponent thin films. Thin Solid Films 420–421, 330–337 (2002)

Levashov, E.A., Petrzhik, M.I., Shtansky, D.V., Kiryukhantsev-Korneev, F.V., Sheveiko, A.N., Valiev, R.Z., Gunderov, D.V., Prokoshkin, S.D., Korotitskiy, A.V., Smolin, AYu.: Nanostructured titanium alloys and multicomponent bioactive films: mechanical behavior at indentation. Mater. Sci. Eng. A 570, 51–62 (2013)

Sonber, J.K., Murthy, T.S.R.Ch., Subramanian, C., Kumar, S., Fotedar, R.K., Suri, A.K.: Investigation on synthesis, pressureless sintering and hot pressing of chromium diboride. Int. J. Refract. Met. Hard Mater. 27, 912–918 (2009)

Audronis, M., Rosli, Z.M., Leyland, A., Kelly, P.J., Matthews, A.: Tribological behaviour of pulsed magnetron sputtered CrB2 coatings examined by reciprocating sliding wear testing against aluminium alloy and steel. Surf. Coat. Technol. 202, 1470–1478 (2008)

Zhang, G., Wang, L., Yan, P., Xue, Q.: Structure and mechanical properties of Cr–B–N films deposited by reactive magnetron sputtering. J. Alloys Compd. 486, 227–232 (2009)

Kiryukhantsev-Korneev, PhV, Trukhanov, P.A., Bondarev, A.V., Shvyndina, N.V., Levashov, E.A.: Structure and properties of tribological coatings in Cu–B system. Phys. Met. Metallogr. 115, 716–722 (2014)

Budna, K.P., Neidhardt, J., Mayrhofer, P.H., Mitterer, C.: Synthesis–structure–property relations for Cr–B–N coatings sputter deposited reactively from a Cr–B target with 20 at.% B. Vacuum 82, 771–776 (2008)

Musil, J.: Hard nanocomposite coatings: thermal stability, oxidation resistance and toughness. Surf. Coat. Technol. 207, 50–65 (2012)

Acknowledgments

The authors gratefully acknowledge the financial support from the Russian Scientific Foundation (Agreement No. 15-19-00203). J. F. Pierson thanks the Industry French Ministry for the FUI-NOMAD project (2009–2013). We thank I. A. Bashkova and N. Zviagintseva for help with tribotests and optical profilometry.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kiryukhantsev-Korneev, P.V., Pierson, J.F., Bychkova, M.Y. et al. Comparative Study of Sliding, Scratching, and Impact-Loading Behavior of Hard CrB2 and Cr–B–N Films. Tribol Lett 63, 44 (2016). https://doi.org/10.1007/s11249-016-0729-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-016-0729-0