Abstract

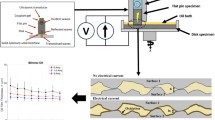

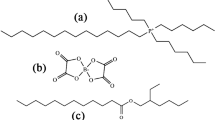

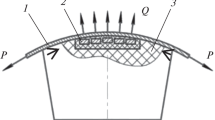

The complex impedance method was developed for measuring the transient behaviors of short-time contacts between colliding steel surfaces, by using an alternating current circuit with a high frequency of 500 kHz at a high sampling rate of 20 MHz. The method was applied to estimate the lubrication effects of simple test lubricants acting at a short-time contact with a duration of 110 μs occurring between a free-falling steel ball and a stationary steel plate, where to minimize the hydrodynamic lubrication effect, the test lubricant was provided on the steel plate as a homogeneous thin film with a thickness of 30 μm. An advantage of the method is in the detection of the beginning and end of the contact. Particularly for wet conditions, although they were apparently unclear in the output voltage signal from the circuit, the modulus of the complex impedance detected them with high accuracy. In addition, using the modulus and argument of the complex impedance, the metallic contact ratio and residual film thickness at the short-time contact can be estimated quantitatively. By using the metallic contact duration determined by the metallic contact ratio, the differences in the boundary lubrication effects were quantified for the selected base oils (i.e., n-decane, n-dodecane, n-tetradecane, and n-hexadecane) and the 30-mM oleic acid solutions dissolved in the base oils at the short-time contact, although the differences in the lubricants did not change the shape of the plastic indentation formed on the steel plate.

Similar content being viewed by others

Abbreviations

- a :

-

Dimensionless coefficient

- b :

-

Dimensionless coefficient

- C f :

-

Capacitance of lubricant film

- d :

-

Thickness of lubricant film

- d min :

-

Residual film thickness

- e r :

-

Coefficient of restitution

- f :

-

Frequency

- f 0 :

-

Frequency of alternator

- \(\bar{F}\) :

-

Mean contact force

- g :

-

Gravitational constant

- h 0 :

-

Initial height of ball

- I 1 :

-

Amplitude of I *1

- I *1 :

-

Alternating current

- j :

-

Imaginary unit

- L :

-

Inductance

- m :

-

Mass of ball

- \(\bar{P}\) :

-

Mean contact pressure

- p p :

-

Plastic flow pressure

- r :

-

Radial position

- R :

-

Resistance of fixed resistor

- R m :

-

Resistance of metallic contact

- S :

-

Apparent contact area

- S f :

-

Area covered with lubricant film

- S m :

-

Area of metallic contact

- S m,max :

-

Maximum of S m

- S m,SP :

-

S m during stable period

- S m0 :

-

S m for dry condition

- S m0,max :

-

Maximum of S m0

- S max :

-

Maximum of S

- S SP :

-

S during stable period

- t :

-

Time

- t A :

-

Time at beginning of contact

- t B :

-

Time at end of contact

- t C :

-

Time of branching

- T MC :

-

Metallic contact duration

- V 0 :

-

Amplitude of V *0

- V *0 :

-

Alternating voltage (input voltage)

- V 1 :

-

Amplitude of V *1

- V *1 :

-

Alternating voltage (output voltage)

- Y :

-

Yield stress

- z :

-

Vertical position

- Z :

-

Modulus of Z *

- Z 0 :

-

Z for dry condition

- Z SP :

-

Z during stable period

- Z * :

-

Complex impedance of contact

- Z *t :

-

Total complex impedance of circuit

- α :

-

Metallic contact ratio

- α max :

-

Maximum of α

- β :

-

Radius of ball

- δ :

-

Indentation depth

- Δt :

-

Duration of contact

- ε :

-

Permittivity of lubricant

- ε 0 :

-

Permittivity of vacuum

- ε r :

-

Relative permittivity

- ζ :

-

Acceleration

- η :

-

Viscosity

- θ :

-

Argument of Z *

- θ 0 :

-

θ for dry condition

- θ SP :

-

θ during stable period

- π :

-

Circular constant

- σ :

-

Resistance of metallic contact for unit area

- φ :

-

Phase difference

- ω :

-

Angular frequency

References

Tabor, D.: Collisions through liquid layers. Engineering 167, 145–147 (1949)

Christensen, H.: The oil film in a closing gap. Proc. Roy. Soc. Lond. A266, 312–328 (1962)

Imado, K., Miyagawa, H., Miura, A., Ueyama, N., Hirano, F.: Behavior of traction oils under impact loads. Tribol. Trans. 37, 378–386 (1994)

Ohno, N., Rahman, M.Z., Tsutsumi, H.: High-pressure short time behavior of traction fluids. Lubr. Sci. 18, 25–36 (2006)

Dowson, D., Jones, D.A.: Lubricant entrapment between approaching elastic solids. Nature 214, 947–948 (1967)

Safa, M.M.A., Gohar, R.: Pressure distribution under a ball impacting a thin lubricant layer. Trans. ASME 108, 372–376 (1986)

Larsson, R., Lundberg, J.: Study of lubricated impact using optical interferometry. Wear 190, 184–189 (1995)

Kaneta, M., Ozaki, S., Nishikawa, H., Guo, F.: Effects of impact loads on point contact elastohydrodynamic lubrication films. Proc. Inst. Mech. Eng. J221, 271–278 (2007)

Kaneta, M., Nishikawa, H., Mizui, M., Guo, F.: Impact elastohydrodynamics in point contacts. Proc. Inst. Mech. Eng. J225, 1–12 (2011)

Dowson, D., Wang, D.: An analysis of the normal bouncing of a solid elastic ball on an oily plate. Wear 179, 29–37 (1994)

Lee, K.M., Cheng, H.S.: The pressure and deformation profiles between two normally approaching lubricated cylinders. Trans. ASME 95, 308–317 (1973)

Archard, J.F., Kirk, M.T.: Lubrication at point contacts. Proc. Roy. Soc. Lond. A261, 532–550 (1961)

Hamilton, G.M., Moore, S.L.: Deformation and pressure in an elastohydrodynamic contact. Proc. Roy. Soc. Lond. A322, 313–330 (1971)

Ten Napel, W.E., Bosma, R.: The influence of surface roughness on the capacitive measurement of film thickness in elastohydrodynamic contacts. Proc. Inst. Mech. Eng. 185, 635–639 (1970)

Smith, A.J., Cameron, A.: Rigid surface films. Proc. Roy. Soc. Lond. A328, 541–560 (1972)

Okabe, H., Watanabe, Y.: Thin residual films between steel–mercury surfaces. ASLE Trans. 25, 33–38 (1982)

Nakano, K., Akiyama, Y.: Simultaneous measurement of film thickness and coverage of loaded boundary films with complex impedance analysis. Tribol. Lett. 22, 127–134 (2006)

Lord, J., Larsson, R.: Film-forming capability in rough surface EHL investigated using contact resistance. Tribol. Int. 41, 831–838 (2008)

Manabe, K., Nakano, K.: Breakdown of oil films and formation of residual films. Tribol. Int. 41, 1103–1113 (2008)

Nakano, K., Manabe, K.: Breakdown processes of boundary films formed by oiliness additives. Tribol. Online 6, 277–283 (2011)

Cameron, A., Crouch, R.F.: Interaction of hydrocarbon and surface-active agent. Nature 198, 475–476 (1963)

Askwith, T.C., Cameron, A., Crouch, R.F.: Chain length of additives in relation to lubricants in thin film and boundary lubrication. Proc. Roy. Soc. Lond. A291, 500–519 (1966)

Grew, W., Cameron, A.: Friction transition temperature effect of matching surfactant and carrier. Nature 214, 429–430 (1967)

Grew, W., Cameron, A.: Role of austenite and mineral oil in lubricant failure. Nature 217, 481–482 (1968)

Grew, W.J.S., Cameron, A.: Thermodynamics of boundary lubrication and scuffing. Proc. Roy. Soc. Lond. A327, 47–59 (1972)

Cameron, A., Day, R.S., Sharma, J.P., Smith, A.J.: Studies in interaction of additive and base stock. ASLE Trans. 19, 195–200 (1976)

Cameron, A.: The role of surface chemistry in lubrication and scuffing. ASLE Trans. 23, 388–392 (1980)

Okabe, H., Kanno, T.: Behavior of polar compounds in lubricating-oil films. ASLE Trans. 24, 459–466 (1981)

Okabe, H., Masuko, M., Sakurai, K.: Dynamic behavior of surface-adsorbed molecules under boundary lubrication. ASLE Trans. 24, 467–473 (1981)

Hirano, F., Sakai, T., Kuwano, N., Ohno, N.: Chain matching between hydrocarbon and fatty acid as interfacial phenomena. Tribol. Int. 20, 186–204 (1987)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nihira, T., Manabe, K., Tadokoro, C. et al. Complex Impedance Measurement Applied to Short-Time Contact Between Colliding Steel Surfaces. Tribol Lett 57, 29 (2015). https://doi.org/10.1007/s11249-015-0478-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-015-0478-5