Abstract

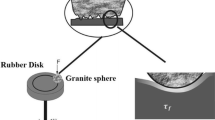

Friction of carbon black- and silica-reinforced elastomers is studied experimentally and theoretically, using Persson’s model. The effect of reinforcement fillers on elasticity was determined by dynamical mechanical analysis. Carbon black-filled samples have a higher Young’s modulus than the silica-filled compounds. Silica-filled rubbers have a higher tan (δ) at lower temperatures and a lower loss tangent at higher temperatures, which is a rough indication for higher wet grip and lower rolling resistance, respectively. Friction tests on a ball-on-disk test rig were performed to study the effect of the reinforcement fillers and their amount on the friction between rubber samples (disks) and relatively smooth or rough granite surfaces (balls). The results were discussed and compared with the friction model presented by Persson. It was shown theoretically and experimentally that hysteresis does not play a significant role in the friction of rubber samples in contact with smooth granite and that it plays a minor role in contact with a rough granite sphere. Therefore, the hysteresis contribution of friction can be neglected in the contact of rubbers with just smooth spheres. Moreover, a higher friction coefficient is seen in samples with a higher content of fillers. Silica-filled compounds show a slightly higher coefficient of friction compared with the carbon black-filled compounds. The effect of attached wear debris to the granite surfaces on the friction level has been studied. The results are supported by SEM and confocal microscopic images of the wear debris itself and wear debris attached to the granite spheres, respectively.

Similar content being viewed by others

Abbreviations

- F f :

-

Total friction force (N)

- F vis :

-

Hysteresis contribution of friction force induced by viscoelastic losses (N)

- τ f(v):

-

Frictional shear stress as a function of velocity (Pa)

- A(v):

-

Real area of contact as a function of velocity (m2)

- μ f :

-

Total coefficient of friction

- F N :

-

Nominal normal load (N)

- σ 0 :

-

Nominal contact pressure (Pa)

- A 0 :

-

Nominal area of contact (m2)

- μ vis :

-

Viscoelastic or hysteresis coefficient of friction

- P(q):

-

Real to the nominal area of contact ratio as a function of wave vector

- ω :

-

Frequency of the applied load to the rubber (rad/s)

- λ :

-

Length scale of the roughness under study (m)

- \(\vec{\varvec{q}}\) :

-

Roughness wave vector (1/m)

- q:

-

Amplitude of the roughness wave vector (1/m)

- q 0 :

-

Lower wave vector cutoff corresponding to the longest wave length of roughness (1/m)

- q 1 :

-

Higher wave vector cutoff corresponding to the shortest wave length of roughness (1/m)

- C(q):

-

Power spectral density of the roughness (m4)

- A(q):

-

Apparent contact area when the surface is smooth on all wave vectors >q (m2)

- ϕ :

-

Angle between the velocity vector and the wave vector \(\vec{\varvec{q}}\) (rad)

- E :

-

Modulus of elasticity (Pa)

- G(ω):

-

The shear modulus (Pa)

- ν :

-

Poisson’s ratio

- τ c :

-

Effective frictional stresses with regard to energy dissipation at a crack opening (Pa)

- τ s :

-

Effective frictional stresses with regard to shearing a thin confined film (Pa)

- G(v):

-

Energy/area to break the interfacial rubber–substrate bond as a function of velocity (w/m2)

- a :

-

Crack-tip radius (m)

- a T :

-

The temperature–frequency viscoelastic horizontal shift factor

- T g :

-

Glass transition temperature (°C)

- ξ :

-

Magnification factor

References

Le Gal, A., Yang, X., Klüppel, M.: Evaluation of sliding friction and contact mechanics of elastomers based on dynamic-mechanical analysis. J. Chem. Phys. 123(1), 014704 (2005)

Claeys, X., Jingang, Y., Alvarez, L., Horowitz, R., Canudas de Wit, C., Richard, L.: Tire friction modeling under wet road conditions. In: American Control Conference, vol. 1793, pp. 1794–1799 (2001)

Lorenz, B., Persson, B.N.J., Fortunato, G., Giustiniano, M., Baldoni, F.: Rubber friction for tire tread compound on road surfaces. J. Phys. Condens. Matter 25(9), 095007 (2013)

O’Boy, D.J., Dowling, A.P.: Tyre/road interaction noise-numerical noise prediction of a patterned tyre on a rough road surface. J. Sound Vib. 323(1–2), 270–291 (2009)

Brancati, R., Strano, S., Timpone, F.: An analytical model of dissipated viscous and hysteretic energy due to interaction forces in a pneumatic tire: theory and experiments. Mech. Syst. Signal Process. 25(7), 2785–2795 (2011)

Rustighi, E., Elliott, S.J., Finnveden, S., Gulyás, K., Mócsai, T., Danti, M.: Linear stochastic evaluation of tyre vibration due to tyre/road excitation. J. Sound Vib. 310(4–5), 1112–1127 (2008)

Susumu, A., Yukio, T., Toshio, M., Akira, A., Kohki, T., Toshio, K., Mamoru, M., Toshiro, Y.: Investigation of environmental problems caused by studded tires of automobiles using PIXE. Nucl. Inst. Methods Phys. Res. B 3(1–3), 516–521 (1984)

Bond, R., Morton, G.F., Krol, L.H.: A tailor-made polymer for tyre applications. Polymer 25(1), 132–140 (1984)

Grosch, K.A.: The rolling resistance, wear and traction properties of tread compounds. Rubber Chem. Technol. 69(3), 495–568 (1996)

Williams, A.R.: Tyre to road interaction: a case for application of research. Tribol. Int. 17(5), 235–241 (1984)

Golden, J.M.: A molecular theory of adhesive rubber friction. J. Phys. A Math. Gen. 8(6), 966–979 (1975)

Rand, C.J., Crosby, A.J.: Insight into the periodicity of Schallamach waves in soft material friction. Appl. Phys. Lett. 89(26), 261907 (2006)

Tabor, D.: The mechanism of rolling friction. II. The elastic range. Proc. R. Soc. Sci. Lond. Ser. A Math. Phys. Sci. 229(1), 198–220 (1955). doi:10.2307/99713

Moore, D.F.: The Friction and Lubrication of Elastomers. Pergamon Press Oxford, New York (1972)

Wriggers, P., Reinelt, J.: Multi-scale approach for frictional contact of elastomers on rough rigid surfaces. Comput. Methods Appl. Mech. Eng. 198(21–26), 1996–2008 (2009)

Persson, B.N.J.: Theory of rubber friction and contact mechanics. J. Chem. Phys. 115(8), 3840–3861 (2001)

Persson, B.N.J.: On the theory of rubber friction. Surf. Sci. 401(3), 445–454 (1998)

Lorenz, B., Persson, B.N.J., Dieluweit, S., Tada, T.: Rubber friction: comparison of theory with experiment. Eur. Phys. J. E 34(12), 1–11 (2011)

Pan, X.D.: Wet sliding friction of elastomer compounds on a rough surface under varied lubrication conditions. Wear 262(5–6), 707–717 (2007)

Patent Application (Michelin). US patent 5,227,425

Persson, B.N.J., Albohr, O., Tartaglino, U., Volokitin, A.I., Tosatti, E.: On the nature of surface roughness with application to contact mechanics, sealing, rubber friction and adhesion. J. Phys. Condens. Matter 17(1), R1–R62 (2005)

Persson, B.N.J., Albohr, O., Heinrich, G., Ueba, H.: Crack propagation in rubber-like materials. J. Phys. Condens. Matter 17(44), R1071–R1142 (2005)

Blau, P.J.: Embedding wear models into friction models. Tribol. Lett. 34(1 SPEC. ISS.), 75–79 (2009)

Boissonnet, L., Duffau, B., Montmitonnet, P.: A wear particle-based model of friction in a polymer-metal high pressure contact. Wear 286–287, 55–65 (2012)

Williams, M.L., Landel, R.F., Ferry, J.D.: The temperature dependence of relaxation mechanisms in amorphous polymers and other glass-forming liquids. J. Am. Chem. Soc. 77(14), 3701–3707 (1955)

Ferry, J.D.: Viscoelastic Properties of Polymers. Wiley, New York (1980)

Fritzsche, J., Klüppel, M.: Structural dynamics and interfacial properties of filler-reinforced elastomers. J. Phys. Conden. Matter 23(3), 035104 (2011)

Klüppel, M.: Evaluation of viscoelastic master curves of filled elastomers and applications to fracture mechanics. J. Phys. Conden. Matter 21(3), 035104 (2009)

Lorenz, B., Pyckhout-Hintzen, W., Persson, B.N.J.: Master curve of viscoelastic solid: using causality to determine the optimal shifting procedure, and to test the accuracy of measured data. Polymer 55(2), 565–571 (2014). doi:10.1016/j.polymer.2013.12.033

Cochet, P., Barriquand, L., Bomal, Y., Touzet, S.: Precipitated Silica in Tire Tread. Paper presented at the ACS, Rubber Division, Cleveland, OH, Oct. 17–20 (1995)

Persson, B.N.J.: Rubber friction: role of the flash temperature. J. Phys. Condens. Matter 18(32), 7789–7823 (2006)

Rodriguez, N.V., Masen, M.A., Schipper, D.J.: Tribologically modified surfaces on elastomeric materials. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 227(5), 398–405 (2013)

Momozono, S., Nakamura, K., Kyogoku, K.: Theoretical model for adhesive friction between elastomers and rough solid surfaces. J. Chem. Phys. 132(11), 114105 (2010)

Bahadur, S.: The development of transfer layers and their role in polymer tribology. Wear 245(1–2), 92–99 (2000)

Mergler, Y.J., Schaake, R.P., Huis in’t Veld, A.J.: Material transfer of POM in sliding contact. Wear 256(3–4), 294–301 (2004)

Acknowledgments

This project is carried out in the framework of the innovation program “GO Gebundelde Innovatiekracht,” and funded by the “European Regional Development Fund,” “Regio Twente” and “Provincie Overijssel.” The project partners Apollo Tyres Global R&D B.V., University of Twente (Tire–Road Consortium), Reef Infra, Stemmer Imaging B.V. and the Provincie Gelderland are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mokhtari, M., Schipper, D.J. & Tolpekina, T.V. On the Friction of Carbon Black- and Silica-Reinforced BR and S-SBR Elastomers. Tribol Lett 54, 297–308 (2014). https://doi.org/10.1007/s11249-014-0334-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-014-0334-z