Abstract

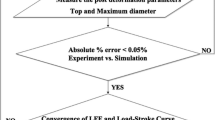

To further understand the tribological performance in metal forming, it is critical to accurately evaluate the friction between tool and workpiece. However, the unclear contact conditions at the interfaces and the complex mechanisms of the tribology lead to challenges to assess friction in metal forming processes. In this study, a friction evaluation method by the barrel compression test and its principle model were proposed based on the theoretical analysis and the numerical simulations. Besides the friction factor at the die–specimen interfaces and the initial aspect ratio of the specimen, the strain hardening exponent of the specimen was found to affect the barreling profiles based on the theoretical analysis. Furthermore, the effects of the three influencing factors, including the friction factor at the interfaces, the initial aspect ratio and the strain hardening exponent of the specimen, on the defined barreling factor were numerically analyzed by the finite element method. A predictive model of the barreling factor accounting for these three factors was developed. A friction evaluation method, proposed based on this model, was implemented by various cylinder compression experiments of CuZn40 brass. The method proposed in this study provided a convenient means to identify the contact friction in metal forming processes.

Similar content being viewed by others

References

Engel, U., Eckstein, R.: Microforming—from basic research to its realization. J. Mater. Process. Tech. 125–126, 35–44 (2002)

Kim, G.-Y., Koc, M., Ni, J.: Experimental and numerical investigations on microcoining of stainless steel 304. J. Manuf. Sci. Eng. Trans. ASME 130(4), 041017 (2008)

Yao, Z., Kim, G.-Y., Faidley, L., Zou, Q., Mei, D., Chen, Z.: Effects of superimposed high-frequency vibration on deformation of aluminum in micro/meso-scale upsetting. J. Mater. Process. Tech. 212(3), 640–646 (2012)

Yao, Z., Kim, G.-Y., Faidley, L., Zou, Q., Mei, D., Chen, Z.: Experimental study of high-frequency vibration assisted micro/mesoscale forming of metallic materials. J. Manuf. Sci. Eng. Trans. ASME 133(6), 061009 (2011)

Engel, U.: Tribology in microforming. Wear 260(3), 265–273 (2004)

Avitzur, B.: Handbook of Metal-Forming Processes. Wiley, New York (1983)

Jung, K.H., Lee, H.C., Ajiboye, J.S., Im, Y.T.: Characterization of frictional behavior in cold forging. Tribol. Lett. 37(2), 353–359 (2010)

Yang, T.S., Lo, S.W.: Contact simulation for predicting surface topography in metal forming. Tribol. Lett. 23(2), 121–129 (2006)

Wang, C., Guo, B., Shan, D., Bai, X.: Tribological behaviors of DLC film deposited on female die used in strip drawing. J. Mater. Process. Tech. 213(3), 323–329 (2013)

Blau, P.J.: Friction Science and Technology: from Concepts to Applications, 2nd edn. CRC Press, Boca Raton, FL (2009)

Avitzur, B.: Metal Forming: Processes and Analysis, McGraw-Hill Series in Materials Science and Engineering. McGraw-Hill, New York (1968)

Yeh, W.C., Wu, M.C.: A variational upper-bound method for analysis of upset forging of rings. J. Mater. Process. Tech. 170(1–2), 392–402 (2005)

Altinbalik, T., Çan, Y.: An upper bound analysis and determination of the barrelling profile in upsetting. Indian J. Eng. Mater. Sci. 18(6), 416–424 (2011)

Sofuoglu, H., Rasty, J.: On the measurement of friction coefficient utilizing the ring compression test. Tribol. Int. 32(6), 327–335 (1999)

Ebrahimi, R., Najafizadeh, A.: A new method for evaluation of friction in bulk metal forming. J. Mater. Process. Tech. 152(2), 136–143 (2004)

Dadras, P.: A semi-empirical solution to upset forging. J. Eng. Ind. Trans. ASME 103(4), 478–483 (1981)

Lee, C.H., Altan, T.: Influence of flow stress and friction upon metal flow in upset forging of rings and cylinders. J. Eng. Ind. Trans. ASME 94(3), 775–782 (1972)

Schey, J.A., Venner, T.R., Takomana, S.L.: Shape changes in the upsetting of slender cylinders. J. Eng. Ind. Trans. ASME 104(1), 79–83 (1982)

Sivaprasad, P.V., Davies, C.H.J.: An assessment of the interface friction factor using the geometry of upset specimens. Model. Simul. Mater. Sci. Eng. 13(3), 355–360 (2005)

Kaviti, A.K., Prakash, O., Vishwanath, P.: Friction calibration map for determination of equal frictional conditions. Adv. Appl. Sci. Res. 2(5), 279–289 (2011)

Kaviti, A.K., Prakash, O., Kumar, P.V.: Prediction of coefficient of friction for aluminum billet. Arch. Appl. Sci. Res. 3(4), 328–335 (2011)

Li, Y.P., Onodera, E., Chiba, A.: Evaluation of friction coefficient by simulation in bulk metal forming process. Metall. Mater. Trans. A 41A(1), 224–232 (2010)

Hsu, Y.C., Yang, T.S., Sung, S.Y., Chang, S.Y.: Constructing the predictive models of friction coefficient using cylindrical compression testing. Mater. Sci. Forum 505–507, 745–750 (2006)

Li, Y.P., Onodera, E., Chiba, A.: Friction coefficient in hot compression of cylindrical sample. Mater. Trans. 51(7), 1210–1215 (2010)

Solhjoo, S.: A note on “barrel compression test”: a method for evaluation of friction. Comp. Mater. Sci. 49(2), 435–438 (2010)

Campbell, F.C.: Elements of Metallurgy and Engineering Alloys. ASM International, Materials Park, Ohio (2008)

Banerjee, J.K.: Barreling of solid cylinders under axial-compression. J. Eng. Mater. Trans. ASME 107(2), 138–144 (1985)

Çetinarslan, C.S.: Effect of aspect ratio on barreling contour and variation of total surface area during upsetting of cylindrical specimen. Mater. Des. 28(6), 1907–1913 (2007)

Narayanasamy, R., Sathiyanarayanan, S., Ponalagusamy, R.: A study on barrelling in magnesium alloy solid cylinders during cold upset forming. J. Mater. Process. Tech. 101(1–3), 64–69 (2000)

Reardon, A.C.: Metallurgy for the Non-metallurgist, 2nd edn. ASM International, Materials Park, Ohio (2011)

Lai, C.-D., Murthy, D.N., Xie, M.: Weibull distributions and their applications. In: Pham, H. (ed.) Springer Handbook of Engineering Statistics, pp. 63–78. Springer, London (2006)

Malama, B., Kulatilake, P.: Models for normal fracture deformation under compressive loading. Int. J. Rock Mech. Min. 40(6), 893–901 (2003)

Stroud, P.D., Sydoriak, S.J., Riese, J.M., Smith, J.P., Mniszewski, S.M., Romero, P.R.: Semi-empirical power-law scaling of new infection rate to model epidemic dynamics with inhomogeneous mixing. Math. Biosci. 203(2), 301–318 (2006)

Yao, Z., Kim, G.-Y., Wang, Z., Faidley, L., Zou, Q., Mei, D., Chen, Z.: Acoustic softening and residual hardening in aluminum: modeling and experiments. Int. J. Plast. 39, 75–87 (2012)

Hatch, J.E.: Aluminum: Properties and Physical Metallurgy. American Society for Metals, Metals Park, Ohio (1984)

Gurugubelli, S.N.: Experimental investigations on bulge profile of Al–Mg alloys during cold upsetting. Int. J. Sci. Adv. Tech. 2(5), 184–186 (2012)

Sahin, M., Çetinarslan, C.S., Misirli, C.: Materials flow for different lubricants during cold forming. Ind. Lubr. Tribol. 65(5) (2013, in press). http://www.emeraldinsight.com/journals.htm?articleid=17047078

Acknowledgments

The authors greatly appreciate the financial supports from Science Fund for Creative Research Groups of National Natural Science Foundation of China (Grant No. 51221004), National Natural Science Foundation of China (Grant No. 50930005, 51175460), Zhejiang Provincial Natural Science Foundation of China (Grant No. Z1090373) and the Research Fund for the Doctoral Program of Higher Education of China (Grant No. 20110101110011).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yao, Z., Mei, D., Shen, H. et al. A Friction Evaluation Method Based on Barrel Compression Test. Tribol Lett 51, 525–535 (2013). https://doi.org/10.1007/s11249-013-0164-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-013-0164-4