Abstract

Understanding the erosion mechanism is a key to improve the performance of material subjected to erosive condition. Capability to predict the erosion mechanism could prove to be useful tool. In this work, a parameter named “erosion mechanism identifier,” ξ, is proposed to predict the erosion mechanism in materials. Suitability of ξ in predicting erosion mechanism of ductile and brittle materials was evaluated using the data reported in the literature. It was observed that ξ is able to predict the erosion mechanism for both categories of material. The predictability of ξ was not restrained by different operating conditions.

Similar content being viewed by others

Abbreviations

- E :

-

Erosion rate

- H :

-

Hardness

- K :

-

Toughness

- V :

-

Volume loss

- m :

-

Mass of erodent particles

- v :

-

Velocity of erodent particles

- η :

-

Erosion efficiency

- ξ :

-

Erosion mechanism identifier

- σ :

-

Critical stress

- σ u :

-

Ultimate tensile strength

- σ R :

-

Transverse rupture strength

- τ u :

-

Ultimate shear strength

References

Finnie, I.: Some reflections on the past and future of erosion. Wear 186–187, 1–10 (1995)

Stachowiak, G.W., Batchelor, A.W.: Engineering Tribology. Butterworth-Heinemann, Burlington (2005)

Levy, A.V.: Solid Particle Erosion and Erosion-Corrosion of Materials. ASM International, Ohio (1995)

Finnie, I.: Erosion of surfaces by solid particles. Wear 3(2), 87–103 (1960)

Hutchings, I.M.: Tribology: Friction and Wear of Engineering Materials. Edward Arnold, London (1992)

Sundararajan, G., Roy, M., Venkataraman, B.: Erosion efficiency-a new parameter to characterize the dominant erosion micromechanism. Wear 140(2), 369–381 (1990)

Kleis, I.: Probleme der Bestimmung des Strahlverschleisses bei metallen. Wear 13(3), 199–215 (1969)

Cousens, A.K., Hutchings, I.M.: A critical study of the erosion of an aluminium alloy by solid spherical particles at normal impingement. Wear 88(3), 335–348 (1983)

Reddy, A.V., Sundararajan, G.: Erosion behaviour of ductile materials with a spherical non-friable erodent. Wear 111(3), 313–323 (1986)

Sheldon, G.L., Finnie, I.: On the ductile behavior of nominally brittle materials during erosive cutting. J. Eng. Ind. 88(4), 387–392 (1966)

IImar Kleis, P.K.: Solid Particle Erosion: Occurrence Prediction and Control. Springer, London (2008)

Gahr, K.H.Z.: Modelling of two-body abrasive wear. Wear 124(1), 87–103 (1988)

Zu, J.B., Burstein, G.T., Hutchings, I.M.: A comparative study of the slurry erosion and free-fall particle erosion of aluminium. Wear 149(1–2), 73–84 (1991)

Guo, D.Z., Wang, L.J., Li, J.Z.: Erosive wear of low chromium white cast iron. Wear 161(1–2), 173–178 (1993)

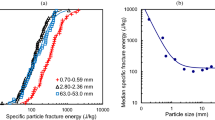

Abouel-Kasem, A.: Particle size effects on slurry erosion of 5117 steels. J. Tribol. 133(1), 014502 (2011)

Grewal, H.S., Bhandari, S., Singh, H.: Parametric study of slurry-erosion of hydroturbine steels with and without detonation gun spray coatings using taguchi technique. Metall. Mater. Trans. A 43(9), 3387–3401 (2012)

Chauhan, A.K., Goel, D.B., Prakash, S.: Erosion behaviour of hydro turbine steels. Bull. Mater. Sci. 31(2), 115–120 (2008)

Chauhan, A.K., Goel, D.B., Prakash, S.: Solid particle erosion behaviour of 13Cr–4Ni and 21Cr–4Ni–N steels. J. Alloy. Compd. 467(1–2), 459–464 (2009)

Ambrosini, L., Bahadur, S.: Erosion of AISI 4140 steel. Wear 117(1), 37–48 (1987)

Brown, R., Edington, J.W.: Erosion of copper single crystals under conditions of 30° incidence. Wear 79(3), 335–346 (1982)

Fuyan, L., Hesheng, S.: The effect of impingement angle on slurry erosion. Wear 141(2), 279–289 (1991)

Grewal, H.S., Singh, H.: To Study the Effect of Impingement Angle on Slurry Erosion Behaviour of Aluminium and Cast Iron. Report (2012)

Wright, I.G., Shetty, D.K., Clauer, A.H.: Slurry erosion of WC-Co cermets and its relationship to materials properties. In: Field, J.E., Corney, N.S. (eds.) Proceedings 6th International Conference Erosion by Liquid and Solid Impact, Cambridge, UK September 1983. Cavendish Laboratory, University of Cambridge, Cambridge (1983)

Fang, Q., Sidky, P.S., Hocking, M.G.: Erosion and corrosion of PSZ-zirconia and the t-m phase transformation. Wear 233–235, 615–622 (1999)

Oka, Y.I., Yoshida, T.: Practical estimation of erosion damage caused by solid particle impact: part 2: mechanical properties of materials directly associated with erosion damage. Wear 259(1–6), 102–109 (2005)

Bellman Jr, R., Levy, A.: Erosion mechanism in ductile metals. Wear 70(1), 1–27 (1981)

Allen, C., Sheen, M., Williams, J., Pugsley, V.A.: The wear of ultrafine WC-Co hard metals. Wear 250(1–12), 604–610 (2001)

Beste, U., Hammerström, L., Engqvist, H., Rimlinger, S., Jacobson, S.: Particle erosion of cemented carbides with low Co content. Wear 250(1–12), 809–817 (2001)

Bhagat, R.B., Conway Jr, J.C., Amateau, M.F., Brezler Iii, R.A.: Tribological performance evaluation of tungsten carbide-based cermets and development of a fracture mechanics wear model. Wear 201(1–2), 233–243 (1996)

Hussainova, I., Kolesnikova, A., Hussainov, M., Romanov, A.: Effect of thermo-elastic residual stresses on erosive performance of cermets with core-rim structured ceramic grains. Wear 267(1–4), 177–185 (2009)

Hussainova, I., Kubarsepp, J., Pirso, J.: Mechanical properties and features of erosion of cermets. Wear 250(1–12), 818–825 (2001)

Hussainova, I.: Microstructure and erosive wear in ceramic-based composites. Wear 258(1–4), 357–365 (2005)

Hussainova, I., Pirso, J., Antonov, M., Juhani, K., Letunovits, S.: Erosion and abrasion of chromium carbide based cermets produced by different methods. Wear 263(7–12), 905–911 (2007)

Anya, C.C.: Wet erosive wear of alumina and its composites with SiC nano-particles. Ceram. Int. 24(7), 533–542 (1998)

Fang, Q., Xu, H., Sidky, P.S., Hocking, M.G.: Erosion of ceramic materials by a sand/water slurry jet. Wear 224(2), 183–193 (1999)

Jeng, C.-A., Huang, J.-L., Lee, S.-Y., Hwang, B.-H.: Erosion damage and surface residual stress of Cr3C2/Al2O3 composite. Mater. Chem. Phys. 78(1), 278–287 (2003)

Choi, H.-J., Han, D.-H., Park, D.-S., Kim, H.-D., Han, B.-D., Lim, D.-S., Kim, I.-S.: Erosion characteristics of silicon nitride ceramics. Ceram. Int. 29(6), 713–719 (2003)

Deng, J.: Wear behaviors of ceramic nozzles with laminated structure at their entry. Wear 266(1–2), 30–36 (2009)

ASM International: Atlas of Stress-Strain Curves. ASM International, Materials Park, OH (2002)

Acknowledgments

Authors thankfully acknowledge the financial assistance provided by Council of Scientific and Industrial Research (CSIR), India, under project title “Development of Slurry Erosion Resistant Coatings for Hydroturbines,” File no.: 22(0604)/12/EMR-II.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Grewal, H.S., Agrawal, A. & Singh, H. Identifying Erosion Mechanism: A Novel Approach. Tribol Lett 51, 1–7 (2013). https://doi.org/10.1007/s11249-013-0156-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-013-0156-4