Abstract

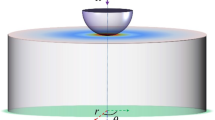

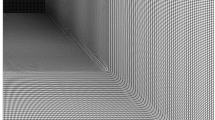

Correlation of contact problems is discussed in a detailed manner with focus on spherical contact. The finite element method is used to determine appropriate stress quantities, representative stresses, aiming at a general description of contact quantities such as mean contact pressure, and the size of the contact area. It is shown that the mean contact pressure can be well described by a single master curve, while this is not so for the size of the contact area. The latter feature is explained partly by a pronounced effect from elastic deformation, but is also shown that large deformation effects can have a substantial influence on correlation attempts. The analysis is restricted to classical Mises elastoplasticity, but the results can also serve as a guideline for similar attempts when using more advanced constitutive modeling. An obvious application of the present results concerns material characterization by indentation testing.

Similar content being viewed by others

References

Hertz, H.: Uber die Berührung fester elastischer Körper. J. Reine Angew. Math. 92, 156–171 (1882)

Tabor, D.: Hardness of metals. Oxford University Press, London (1951)

Johnson, K.L.: The correlation of indentation experiments. J. Mech. Phys. Solids 18, 115–126 (1970)

Johnson, K.L.: Contact mechanics. Cambridge University Press, Cambridge (1985)

Storåkers, B., Biwa, S., Larsson, P.L.: Similarity analysis of inelastic contact. Int. J. Solids Struct. 34, 3061–3083 (1997)

Mesarovic, S.D., Fleck, N.A.: Frictionless indentation of dissimilar elastic–plastic spheres. Proc. R. Soc. Lond. A455, 2707–2728 (1999)

Mesarovic, S.D., Fleck, N.A.: Spherical indentation of elastic–plastic solids. Int. J. Solids Struct. 37, 7071–7091 (2000)

Skrinjar, O., Larsson, P.L., Storåkers, B.: Local contact compliance relations at compaction of composite powders. J. Appl. Mech. 74, 164–168 (2007)

Chaudhri, M.M.: A note on a common mistake in the analysis of nanoindentation data. J. Mater. Res. 16, 336–339 (2001)

Larsson, P.L.: Investigation of sharp contact at rigid plastic conditions. Int. J. Mech. Sci. 43, 895–920 (2001)

Larsson, P.L.: On the mechanical behavior of global parameters in material characterization by sharp indentation testing. J. Test. Eval. 32, 310–321 (2004)

Giannakopoulos, A.E., Larsson, P.L., Vestergaard, R.: Analysis of Vickers indentation. Int. J. Solids Struct. 31, 2679–2708 (1994)

Larsson, P.L., Söderlund, E., Giannakopoulos, A.E., Rowcliffe, D.J., Vestergaard, R.: Analysis of Berkovich indentation. Int. J. Solids Struct. 33, 221–248 (1996)

Biwa, S., Storåkers, B.: Analysis of fully plastic Brinell indentation. J. Mech. Phys. Solids 43, 1303–1334 (1995)

Ogbonna, N., Fleck, N.A., Cocks, A.C.F.: Transient creep analysis of ball indentation. Int. J. Mech. Sci. 37, 1179–1202 (1995)

Bartier, O., Hernot, X.: Phenomenological study of parabolic and spherical indentation of elastic-ideally plastic material. Int. J. Solids Struct. 49, 2015–2026 (2012)

Atkins, A.G., Tabor, D.: Plastic indentation in metals with cones. J. Mech. Phys. Solids 13, 149–164 (1965)

Pethica, J.B., Hutchings, R., Oliver, W.C.: Hardness measurements at penetration depths as small as 20 nm. Philos. Mag. A48, 593–606 (1983)

Doerner, M.F., Gardner, D.S., Nix, W.D.: Plastic properties of thin films on substrates as measured by submicron indentation hardness and substrate curvature techniques. J. Mater. Res. 1, 845–851 (1986)

Larsson, P.L.: Similarity methods for analysing indentation contact problems-advantages and disadvantages. J. Mater. Proc. Tech. 202, 15–21 (2008)

Suresh, S., Giannakopoulos, A.E.: A new method for estimating residual stresses by instrumented sharp indentation. Acta Mater. 46, 5755–5767 (1998)

Carlsson, S., Larsson, P.L.: On the determination of residual stress and strain fields by sharp indentation testing. Part I. Theoretical and numerical analysis. Acta Mater. 49, 2179–2191 (2001)

Swadener, J.G., Taljat, B., Pharr, G.M.: Measurement of residual stress by load and depth sensing indentation with spherical indenters. J. Mater. Res. 16, 2091–2102 (2001)

Eriksson, C.L., Larsson, P.L., Rowcliffe, D.J.: Strain-hardening and residual stress effects in plastic zones around indentations. Mater. Sci. Eng. A 340, 193–203 (2003)

Huber, N., Heerens, J.: On the effect of a general residual stress state on indentation and hardness testing. Acta Mater. 56, 6205–6213 (2008)

Fleck, N.A.: On the cold compaction of powders. J. Mech. Phys. Solids 43, 1409–1431 (1995)

Larsson, P.L., Biwa, S., Storåkers, B.: Analysis of cold and hot isostatic compaction. Acta Mater. 44, 3655–3666 (1996)

Storåkers, B., Fleck, N.A., McMeeking, R.M.: The visco-plastic compaction of composite powders. J. Mech. Phys. Solids 47, 785–815 (1999)

Heyliger, P.R., McMeeking, R.M.: Cold plastic compaction of powders by a network model. J. Mech. Phys. Solids 49, 2031–2054 (2001)

Pizette, P., Martin, C.L., Delette, G., Sornay, P., Sans, F.: Compaction of aggregated ceramic powders: from contact law to fracture and yield surfaces. Powder Technol. 198, 240–250 (2010)

Bucaille, J.L., Felder, E., Hochstetter, G.: Mechanical analysis of the scratch test on elastic and perfectly plastic materials with three-dimensional finite element modeling. Wear 249, 422–432 (2001)

Holmberg, K., Laukkanen, A., Ronkainen, H., Wallin, K., Varjus, S.: A model for stresses, crack generation and fracture toughness calculation in scratched TiN-coated steel surfaces. Wear 254, 278–291 (2003)

Wredenberg, F., Larsson, P.L.: On the numerics and correlation of scratch testing. J. Mech. Mater. Struct. 2, 573–594 (2007)

Bellemare, S.C., Dao, M., Suresh, S.: Effects of mechanical properties and surface friction on elasto-plastic sliding contact. Mech. Mater. 40, 206–219 (2008)

Wredenberg, F., Larsson, P.L.: Scratch testing of metals and polymers: experiments and numerics. Wear 266, 76–83 (2009)

Meyer, E.: Untersuchen uber Härteprufung und Härte. Z. Ver. deutscher Ing. 52, 645–654 (1908)

O’Neill, H.: The significance of tensile and other mechanical test properties of metals. Proc. Inst. Mech. Eng. 151, 116–130 (1944)

Kral, E.R., Komvopoulos, K., Bogy, D.B.: Elastic-plastic finite element analysis of repeated indentation of a half-space by a rigid sphere. J. Appl. Mech. 60, 829–841 (1993)

Brinell, J.A.: Memoire sur les epreuves a bille en acier. Congres International des Methodes d’Essai des Materiaux de. Construction 2, 83–94 (1901)

ABAQUS: Abaqus 6.9. Dassault Systemes Simula Corp., Providence, RI (2009)

Larsson, P.L.: Modelling of sharp indentation experiments: some fundamental issues. Philos. Mag. 86, 5155–5177 (2006)

Norbury, A.L., Samuel, T.: The recovery and sinking-in or piling-up of material in the Brinell test, and the effect of these factors on the correlation of the Brinell with certain other hardness tests. J. Iron Steel Inst. 117, 673–687 (1928)

Chaudhri, M.M.: Strain hardening around spherical indentations. Phys. Status Solidi A 182, 641–652 (2000)

Mesarovic, S.D., Johnson, K.L.: Adhesive contact of elastic-plastic spheres. J. Mech. Phys. Solids 48, 2009–2033 (2000)

Olsson, E., Larsson, P.L.: On force-displacement relations at contact between elastic-plastic spheres (2013) doi:10.1016/j.jmps.2013.01.004

Timothy, S.P., Pearson, J.M., Hutchings, I.M.: The contact pressure distribution during plastic compression of lead spheres. Int. J. Mech. Sci. 29(10), 713–719 (1987)

Chaudhri, M.M., Hutchings, I.M.: Strength measurements on rapidly solidified metal particles. J. Mater. Sci. Lett. 3, 79–82 (1984)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Olsson, E., Larsson, PL. On the Appropriate Use of Representative Stress Quantities at Correlation of Spherical Contact Problems. Tribol Lett 50, 221–232 (2013). https://doi.org/10.1007/s11249-013-0114-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-013-0114-1