Abstract

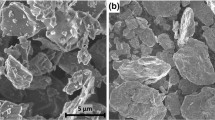

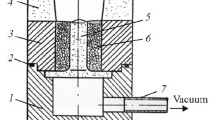

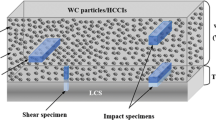

An niobium carbide (NbC) particle-reinforced iron matrix composite was fabricated by compounding gray cast iron with niobium wires through an in situ technique comprised of an infiltration casting process and a subsequent heat treatment. The NbC particles in the reinforcement phase were synthesized in situ through the reaction between niobium from niobium wires and carbon from the graphite phases produced by the heat treatment in gray cast iron. The microstructure and wear-resistance of the bulk niobium particle-reinforced iron matrix composite was studied at different NbC particle volume fractions (8, 15, 22, and 28 vol%), by scanning electron microscope, X-ray diffraction, and a wear tester. The NbC particles were observed to form tiny cuboids and nearly spherical particles which were evenly distributed in the matrix. The particle size of the NbC reinforcement was about 0.3–3.5 μm. The relative wear resistance of the bulk composite increased with increasing NbC volume fraction, and the wear resistance of the composite was 5.9-fold higher than that of the gray cast iron under a 20N load and at a 28 vol% volume fraction. Wear performance of the composite at different NbC particle volume fraction values was also analyzed.

Similar content being viewed by others

References

Zuhailawati, H., Yong, T.L.: Consolidation of dispersion strengthened copper–niobium carbide composite prepared by in situ and ex situ methods. Mater. Sci. Eng. A 505, 27–30 (2009)

Zuhailawati, H., Mahani, Y.: Effects of milling time on hardness and electrical conductivity of in situ Cu–NbC composite produced by mechanical alloying. J. Alloys Compd. 476, 142–146 (2009)

Daoush, W.M., Park, H.S., Lee, K.H., Moustafa, S.F., Hong, S.H.: Effect of binder compositions on microstructure, hardness and magnetic properties of (Ta,Nb)C–Co and (Ta,Nb)C–Ni cemented carbides. Int. J. Refract. Met. Hard. Mater. 27, 669–675 (2009)

Tjong, S.C., Ma, Z.Y.: Microstructural and mechanical characteristics of in situ metal matrix composites. Mater. Sci. Eng. R 29, 49–113 (2000)

Thümmler, F., Gutsfeld, C.: Sintered steels with high content of hard phases: a new class of wear resistant materials. Powder Metall. 23, 285–290 (1991)

Bowden, F.P., Moore, A.W., Tabor, D.: The ploughing and adhesion of sliding metals. J. Appl. Phys. 14, 80–91 (1943)

Acknowledgments

The authors acknowledge the financial support from the National Natural Science Foundation of China (No. 50974101).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhong, L., Xu, Y. & Ye, F. In Situ NbC Particulate-Reinforced Iron Matrix Composite: Microstructure and Abrasive Wear Characteristics. Tribol Lett 47, 253–259 (2012). https://doi.org/10.1007/s11249-012-9977-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-012-9977-9