Abstract

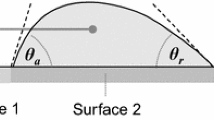

Recent research has shown that hydrodynamic lubrication is an effective means of reducing friction in high sliding micro-electromechanical systems (MEMS). At high speeds, however, such lubrication can lead to increased friction due to viscous drag. This article describes a series of hydrodynamic tests on a silicon MEMS contact lubricated with a blend of hexadecane and a multiply-alkylated cyclopentane (MAC). Results show that the presence of the MAC reduces hydrodynamic friction compared with neat hexadecane. Such behaviour is contrary to conventional hydrodynamic theory, since the viscosity of the MAC—a mixture of di- and tri-(2-octyldodecyl)-cyclopentane—is significantly higher than that of neat hexadecane. This effect increases with MAC concentration up to an optimum value of 3 wt%, where the hydrodynamic friction coefficient at 15,000 rpm is reduced from 0.5 to 0.3. Above this concentration, friction begins to rise due to the overriding effect of increasing viscosity. The viscosity of the blended lubricant increased monotonically with MAC concentration, when measured using both a Stabinger and an ultra-high shear viscometer. In addition to this, no reduction in friction was observed when a squalane–hexadecane blend of equal viscosity was tested. This suggests that some property of the MAC–hexadecane lubricant, other than its viscosity, is influencing hydrodynamic lubrication. A tentative explanation for this behaviour is that the MAC induces the liquid to slip, rather than shear, close to the silicon surfaces. This hypothesis is supported by the fact that the friction reducing ability of the MAC blend was inhibited by the inclusion of octadecylamine—a substance known to form films on silicon surfaces. Furthermore, the MAC reduces friction in the mixed regime, in a manner suggesting that the formation of a viscous boundary layer. This unusual behaviour may have useful implications for reducing hydrodynamic friction in liquid-lubricated MEMS devices.

Similar content being viewed by others

References

Syms, R.R.A., Zou, H., Stagg, J., Veladi, H.: Sliding-blade MEMS iris and variable optical attenuator. J. Micromech. Microeng. 14(12), 1700 (2004)

Girbau, D., Pradell, L., Lazaro, A., Nebot, A.: Electrothermally actuated RF MEMS switches suspended on a low-resistivity substrate. J. Microelectromech. Syst. 16(5), 1061–1070 (2007)

Chau, K.H.L., Sulouff, R.E.: Technology for the high-volume manufacturing of integrated surface-micromachined accelerometer products. Microelectron. J. (Inc. J. Semicust. ICs) 29(9), 579–586 (1998)

Velten, T., Ruf, H.H., Barrow, D., Aspragathos, N., Lazarou, P., Erik, J., Malek, C.K., Richter, M., Kruckow, J., Wackerle, M.: Packaging of bio-MEMS: strategies, technologies, and applications. IEEE Trans. Adv. Packag. 28(4), 533–546 (2005)

Kim, S.H., Asay, D.B., Dugger, M.T.: Nanotribology and MEMS. Nano Today 2(5), 22–29 (2007)

Maboudian, R., Ashurst, W.R., Carraro, C.: Self-assembled monolayers as anti-stiction coatings for MEMS: characteristics and recent developments. Sens. Actuators A Phys. 82(1–3), 219–223 (2000)

Srinivasan, U., Foster, J.D., Habib, U., Howe, R.T., Maboudian, R., Senft, D.C., Dugger, M.T.: Lubrication of polysilicon micromechanisms with self-assembled monolayers. In: Conference on Solid State Sensor and Actuator Workshop, Hilton Head, 1 Jun 1998

Srinivasan, U., Houston, M.R., Rowe, R.T., Maboudian, R.: Self-assembled fluorocarbon films for enhanced stiction reduction. In: International Conference on Solid State Sensors and Actuators, TRANSDUCERS, Chicago (1997)

Smallwood, S.A., Eapen, K.C., Patton, S.T., Zabinski, J.S.: Performance results of MEMS coated with a conformal DLC. Wear 260(11‚Äì12), 1179–1189 (2006)

Tagawa, M., Ikemura, M., Nakayama, Y., Ohmae, N.: Effect of water adsorption on microtribological properties of hydrogenated diamond-like carbon films. Tribol. Lett. 17(3), 575–580 (2004)

Houston, M.R., Howe, R.T., Maboudian, R.: Effect of hydrogen termination on the work of adhesion between rough polycrystalline silicon surfaces. J. Appl. Phys. 81(8), 3474–3483 (1997)

Asay, D., Dugger, M., Kim, S.: In situ vapor-phase lubrication of MEMS. Tribol. Lett. 29(1), 67–74 (2008)

Ashurst, W.R., Carraro, C., Maboudian, R.: Vapor phase anti-stiction coatings for MEMS. IEEE Trans. Device Mater. Reliab. 3(4), 173–178 (2003)

Potter, C.N.: Hermetic MEMS package and method of manufacture. U.S. Patent No. 7,358,106 B22005. Stellar MicroDevices, Inc., Austin

Asay, D.B., Dugger, M.T., Ohlhausen, J.A., Kim, S.H.: Macro- to nanoscale wear prevention via molecular adsorption. Langmuir 24(1), 155–159 (2007)

Ku, I.S.Y., Reddyhoff, T., Holmes, A.S., Spikes, H.A.: Wear of silicon surfaces in MEMS. Wear 271(7–8), 1050–1058 (2011)

Ku, I.S.Y., Reddyhoff, T., Wayte, R., Choo, J.H., Holmes, A.S., Spikes, H.A.: Lubrication of microelectromechanical devices using liquids of different viscosities. J. Tribol. 134(1), 012002–012007 (2012)

Reddyhoff, T., Ku, I., Holmes, A., Spikes, H.: Friction modifier behaviour in lubricated MEMS devices. Tribol. Lett. 41(1), 239–246 (2011)

Keren, D., Ramanathan, G.P., Mehregany, M.: Micromotor dynamics in lubricating fluids. J. Micromech. Microeng. 4(4), 266 (1994)

Mehregany, M., Dhuler, V.R.: Operation of electrostatic micromotors in liquid environments. J. Micromech. Microeng. 2(1), 1 (1992)

Spikes, H.A.: The half-wetted bearing. Part 1: extended Reynolds equation. Proc. Inst. Mech. Eng. J. Eng. Tribol. 217(1), 1–14 (2003)

Spikes, H.A.: The half-wetted bearing. Part 2: potential application in low load contacts. Proc. Inst. Mech. Eng. J. Eng. Tribol. 217(1), 15–26 (2003)

Choo, J.H., Glovnea, R.P., Forrest, A.K., Spikes, H.A.: A low friction bearing based on liquid slip at the wall. J. Tribol. 129(3), 611–620 (2007)

Choo, J.-H., Forrest, A., Spikes, H.: Influence of organic friction modifier on liquid slip: a new mechanism of organic friction modifier action. Tribol. Lett. 27(2), 239–244 (2007)

Pit, R., Hervet, H., Léger, L.: Direct experimental evidence of slip in hexadecane: solid interfaces. Phys. Rev. Lett. 85(5), 980–983 (2000)

Zhu, Y., Granick, S.: Rate-dependent slip of newtonian liquid at smooth surfaces. Phys. Rev. Lett. 87(9), 096105 (2001)

Venier, C.G., Casserly, E.W.: Multiply-alkylated cyclopentanes (MACs): a new class of synthesized hydrocarbon fluids. Lubr. Eng. 47(7), 586–591 (1991)

Peterangelo, S.C., Gschwender, L., Snyder, C.E., Jones, W.R., Nguyen, Q., Jansen, M.J.: Improved additives for multiply alkylated cyclopentane-based lubricants. J. Synth. Lubr. 25(1), 31–41 (2008)

Dube, M.J., Bollea, D., Jones, W.R., Marchetti, M., Jansen, M.J.: A new synthetic hydrocarbon liquid lubricant for space applications. Tribol. Lett. 15(1), 3–8 (2003)

Ku, I.S.Y., Reddyhoff, T., Choo, J.H., Holmes, A.S., Spikes, H.A.: A novel tribometer for the measurement of friction in MEMS. Tribol. Int. 43(5–6), 1087–1090 (2010)

Smeeth, M., Spikes, H., Gunsel, S.: Boundary film formation by viscosity index improvers. Tribol. Trans. 39(3), 726–734 (1996)

Acknowledgments

This research was supported by the Singapore National Research Foundation under its Competitive Research Program (Award Number: NRF-CRP 2-2007-04). The views expressed herein are those of the authors and are not necessarily those of the Singapore National Research Foundation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Leong, J.Y., Reddyhoff, T., Sinha, S.K. et al. Hydrodynamic Friction Reduction in a MAC–Hexadecane Lubricated MEMS Contact. Tribol Lett 49, 217–225 (2013). https://doi.org/10.1007/s11249-012-0056-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-012-0056-z