Abstract

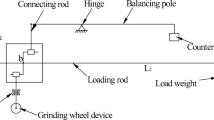

This paper presents a new tribometer developed for a study of the tribological and the viscoelastic behaviour of seat materials used in ball valve. This device simulates the contact configuration and the loading conditions produced during service process (opening–closing valve). The originality of such tribometer lies in the possibility of coupling/decoupling the stress relaxation from the tribological behaviour that allows the evaluation of the interaction between tribology and viscoelastic behaviour. Besides, the tribometer concept and manufactured solution of the same subassemblies as well as the measure system and software for data acquisition and processing results are described. This paper also reports the results of a very first set of experiments conducted on polytetrafluoro ethylene materials under dry rolling conditions. The results obtained show a good correlation with the results found in literature, which encourages more investigation into seats ball valve.

Similar content being viewed by others

References

Briscoe, B.J., Tweedale, P.J.: The influence of debris inclusion on the performance of polymeric seals in ball valves. Tribol. Ser. 14, 259–265 (1989)

Salan, R.F.: Progress towards a realistic numerical model for elastomer reciprocating seals. Seal. Technol. 2007, 7–11 (2007)

Wang, Y.S., Narasimhan, S., Larson, J.M., Larson, J.E., Barber, G.C.: The effect of operating conditions on heavy duty engine valve seat wear. Wear 201, 15–25 (1996)

Prokopovich, P., Theodossiades, S., Rahnejat, H., Hodson, D.: Friction in ultra-thin conjunction of valve seals of pressurised metered dose inhalers. Wear 268(5–6), 845–852 (2010)

Fang, Q., Chetwynd, D.G., Gardner, J.W., Toh, C., Bartlett, P.N.: A preliminary study of conducting polymers as microvalve seals. Mater. Sci. Eng. A 355, 62–67 (2003)

Raparelli, T., Manuello Bertetto, A., Mazza, L.: Experimental and numerical study of friction in an elastomeric seal for pneumatic cylinders. Tribol. Int. 30, 547–552 (1997)

Lee, C.Y., Lin, C.S., Jian, R.Q., Wen, C.-Y.: Simulation and experimentation on the contact width and pressure distribution of lip seals. Tribol. Int. 39, 915–920 (2006)

Nikas, G.K., Sayles, R.S.: Computational model of tandem rectangular elastomeric seals for reciprocating motion. Tribol. Int. 39, 622–634 (2006)

Bottiglione, F., Carbone, G., Mantriota, G.: Fluid leakage in seals: an approach based on percolation theory. Tribol. Int. 42, 731–737 (2009)

Ramalho, A., Kapsa, Ph., Bouvard, G., Abry, J.C., Yoshida, T., Charpentier, M., Bourgeois, M.: Effect of temperatures up to 400°C on the impact-sliding of valve-seat contacts. Wear 267, 777–780 (2009)

Rocha, C.A., Sales, W.F., Barcellos, C.S., Abrão, A.M.: Evaluation of the wear mechanisms and surface parameters when machining internal combustion engine valve seats using PCBN tools. J. Mater. Process. Technol. 145, 397–406 (2004)

Blanchet, I.A., Kennedy, F.E.: Sliding wear mechanism of polytetrafluoroethylene (PTFE) and PTFE composites. Wear 153, 229–243 (1992)

Unal, H., Sen, U., Mimaroglu, A.: Dry sliding wear characteristics of some industrial polymers against steel counterface. Tribol. Int. 37, 727–732 (2004)

Unal, H., Mimaroglu, A.: Friction and wear behaviour of unfilled engineering thermoplastics. Mater. Des. 24, 183–187 (2003)

Felhõs, D., Xu, D., Schlarb, A.K., Váradi, K., Goda, T.: Viscoelastic characterization of an EPDM rubber and finite element simulation of its dry rolling friction. Express Polym. Lett. 2, 157–164 (2008)

Zankin, V.G., Yandell, W.O.: High speed rolling friction on viscoelastic substrates: the determination of the hysteretic damping factor. Wear 72, 157–185 (1981)

Li, T.Q., Zhang, M.Q., Song, L., Zeng, H.M.: Friction induced mechanochemical and mechanophysical changes in high performance semicrystalline polymer. Polymer 40, 4451–4458 (1999)

Myshkin, N.K., Petrokovets, M.I., Kovalev, A.V.: Tribology of polymers: Adhesion, friction, wear, and mass-transfer. Tribol. Int. 38, 910–921 (2005)

Bjork, F., Stenberg, B.: Stress relaxation of a nitrile rubber surrounded by an oil that increases the network density. Polymer 31, 1649–1657 (1990)

Wortmann, F.J.: Analysing the relaxation behaviour of poly(tetrafluoroethylene) in the α-transition region by applying a two-component model. Polymer 37, 2471–2476 (1996)

Acknowledgments

We would like to express our utmost gratitude to the SOPAL Company in SFAX-TUNISIA that provided the funding for this research work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ben Jemaa, M.C., Mnif, R., Fehri, K. et al. Design of a New Tribometer for Tribological and Viscoelasticity Studies of PTFE Valve Seats. Tribol Lett 45, 177–184 (2012). https://doi.org/10.1007/s11249-011-9872-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-011-9872-9