Abstract

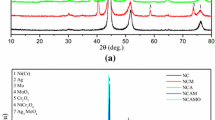

A high-temperature self-lubricating composite NiAl–Cr–Mo–CaF2 was fabricated using the powder metallurgy technique, and the tribological behavior of the composite at a wide range of temperatures (room temperature to 1000 °C) was investigated. The results showed that the composite had a favorable friction coefficient of about 0.2 and an excellent wear resistance of about 1 × 10−5 mm3N−1m−1 at the high temperatures tested (800 and 1000 °C). The excellent self-lubricating performance was attributed to the formation of the glaze film on the worn surface consisting mainly of CaCrO4 and CaMoO4 as high-temperature solid lubricants.

Similar content being viewed by others

References

Spikes, H.: Tribology research in the twenty-first century. Tribol. Int. 34, 789–799 (2001)

Erdemir, A.: A crystal-chemical approach to lubrication by solid oxides. Tribol. Int. 8, 97–102 (2000)

Zhao, J.C.: Ultrahigh-temperature materials for jet engines. MRS Bull. 28, 620–630 (2003)

Sliney, H.E.: Wide temperature spectrum self-lubricating coatings prepared by plasma spraying. Thin Solid Films 64, 217–221 (1979)

DellaCorte, C., Sliney, H.E.: Tribological properties of PM212-a high-temperature, self-lubricating, powder-metallurgy composite. Lubric. Eng. 47, 298–303 (1991)

DellaCorte, C., Sliney, H.E.: Tribological and mechanical comparison of sintered and HIPped PM212: high temperature self-lubricating composites. Lubric. Eng. 48, 877–885 (1992)

DellaCorte, C., Fellenstein, J.A.: The effect of compositional tailoring on the thermal expansion and tribological properties of PS300: a solid lubricant composite coating. Tribol. Trans. 40, 639–642 (1997)

Blanchet, T.A., Kim, J.H., Calabrese, S.J., DellaCorte, C.: Thrust-washer evaluation of self-lubricating PS304 composite coatings in high temperature sliding contact. Tribol. Trans. 45, 491–498 (2002)

Wang, W.C.: Application of a high temperature self-lubricating composite coating on steam turbine components. Surf. Coat. Technol. 177–178, 12–17 (2004)

Ding, C.H., Li, P.L., Ran, G., Tian, Y.W., Zhou, J.N.: Tribological property of self-lubricating PM304 composite. Wear 262, 575–581 (2007)

Yamaguchi, M., Inui, H., Ito, K.: High temperature structural intermetallics. Acta Mater. 48, 307–322 (2000)

Ward-Close, C.M., Minorb, R., Doorbarb, P.J.: Intermetallic-matrix composites-a review. Intermetallics 4, 217–229 (1996)

Deevi, S.C., Sikkat, V.K., Liu, C.T.: Processing, properties, and applications of nickel and iron aluminides. Prog. Mater. Sci. 42, 177–192 (1991)

Gong, K., Luo, H.L., Feng, D., Li, C.H.: Wear of Ni3Al-based materials and its chromium-carbide reinforced composites. Wear 265, 1751–1755 (2008)

Czeppe, T., Wierzbinski, S.: Structure and mechanical properties of NiAl and Ni3Al-based alloys. Int. J. Mech. Sci. 42, 1499–1518 (2000)

Grabk, H.J., Brumm, M.W., Wagemann, B.: The oxidation of NiAl. Mater. Corros. 47, 675–677 (1996)

Huai, K.W., Guo, J.T., Gao, Q., Li, H.T., Yang, R.: Microstructure and mechanical behavior of NiAl-based alloy prepared by powder metallurgical route. Intermetallics 15, 749–752 (2007)

Johnson, D.R., Chen, X.F., Oliver, B.F., Noebe, R.D., Whittenberger, J.D.: Processing and mechanical properties of in situ composites from the NiAl-Cr and the NiAl-(Cr, Mo) eutectic systems. Intermetallics 3, 99–113 (1995)

Murakami, T., Ouyang, J.H., Sasaki, S., Umeda, K., Yoneyama, Y.: High-temperature tribological properties of Al2O3, Ni-20 mass% Cr and NiAl spark-plasma-sintered composites containing BaF2–CaF2 phase. Wear 259, 626–633 (2005)

Ming-Chang, J., Yung-Liang, S.: Wear behaviour of solid lubricants Ag and BaF2–CaF2 obtained by laser surface cladding. Surf. Coat. Technol. 57, 145–150 (1993)

Deadmore, D.L., Sliney, H.E.: Hardness of CaF2 and BaF2 solid lubricants at 25–670°C. NASA-TM-88979 (1987)

Sliney, H.E., Graham, J.W.: Tribological properties of self-lubricating fluoride-metal composites to 900°C (1650°F)—a review and some new developments. NASA Technical Memorandum NASA-TM-X-71575 (1974)

Peterson, M.B., Murray, S.F., Florek, J.J.: Consideration of lubricants for temperatures above 1000°F. ASME Trans 2, 225–234 (1959)

Han, J.S., Jia, J.H., Lu, J.J., Wang, J.B.: High temperature tribological characteristics of Fe-Mo-based self-lubricating composites. Tribol. Lett. 34, 193–200 (2009)

Ouyang, J.H., Sasaki, S., Umeda, K.: The friction and wear characteristics of low-pressure plasma-sprayed ZrO2–BaCrO4 composite coating at elevated temperatures. Surf. Coat. Technol. 154, 131–139 (2002)

Ouyang, J.H., Sasaki, S., Murakami, T., Umeda, K.: Spark-plasma-sintered ZrO2(Y2O3)-BaCrO4 self-lubricating composites for high temperature tribological applications. Ceram. Int. 31, 543–553 (2005)

Jiang, J.R., Stott, F.H., Stack, M.M.: A mathematical model for sliding wear of metals at elevated temperatures. Wear 181–183, 20–31 (1995)

Stott, F.H.: High-temperature sliding wear of metals. Tribol. Int. 35, 489–495 (2002)

Pauschitz, A., Roy, M., Franek, F.: Mechanisms of sliding wear of metals and alloys at elevated temperatures. Tribol. Int. 41, 584–602 (2008)

Acknowledgments

The authors are grateful to the National Natural Science Foundation of China (51075383), the Innovation Group Foundation from NSFC (50721062), and the National 973 Project (2007CB607601) for financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhu, S., Bi, Q., Wu, H. et al. NiAl Matrix High-Temperature Self-Lubricating Composite. Tribol Lett 41, 535–540 (2011). https://doi.org/10.1007/s11249-010-9727-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-010-9727-9