Abstract

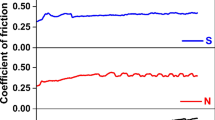

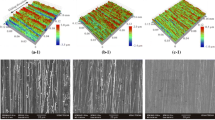

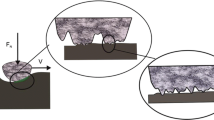

This article deals with the rubber-based friction materials (RBFMs) which can be used in brake system. The physico-mechanical and tribological properties of a series of fiber filled RBFMs containing steel wool and aramid pulp at different concentrations along with a fiber-free reference material were characterized. Rubber–glass transition induced at higher sliding velocities was identified based on the friction fade behavior of the RBFMs. The rubber–glass transition which is inherently originated by viscoelastic response of polymeric binder was found to be influential on the tribological properties of the RBFMs. It was revealed that steel wool increased coefficient of friction (COF) and improved friction recovery behavior at low volume percent (7.5 vol.%) but it aggravated the COF at high concentration of steel wool (15 vol.%) and severe sliding conditions because of harsh abrasive mechanism. Aramid pulp improved the fade behavior at high sliding velocities and increased COF due to formation of sticky contact patches. It was revealed that steel wool increased the wear rate while aramid pulp did not affect the wear rate significantly, contrary to the increase in the friction coefficient of RBFM. SEM analysis was proved to be useful in correlating the wear rates of composites to the topographical changes on the worn surfaces.

Similar content being viewed by others

References

Chang, L., Zhang, Z., Ye, L., Friedrich, K.: Synergistic effects of nanoparticles and traditional tribo-fillers on sliding wear of polymeric hybrid composites. In: Friedrich, K., Schlarb, A.K. (eds.) Tribology of Polymeric Nanocomposites, Engineering Series, vol. 55, pp. 35-61. Elsevier, Amsterdam (2008)

Blau, P.J.: Compositions, functions, and testing of friction brake materials. Technical report by oak ridge national laboratory, ORNL/TM-2001/64, Tennessee (2001)

Yi, G.W., Yan, F.Y.: Mechanical and tribological properties of phenolic resin-based friction composites filled with several inorganic fillers. Wear 262, 121–129 (2007)

Dow, T.A.: Thermoelastic effects in brakes. Wear 59, 213–221 (1980)

Abbasi, F., Shojaei, A., Katbab, A.: Thermal interaction between polymer-based composite friction materials and counterfaces. J Appl Polym Sci 81, 364–369 (2001)

Gibson, P.A.: Composition friction materials for the replacement of cast iron railway blocks. IMechE seminar publication in Railway traction and braking, pp. 75–85 (1996)

Haddadi, E., Abbasi, F., Shojaei, A.: Wear and thermal effects in low modulus polymer-based composite friction materials. J Appl Polym Sci 95, 1181–1188 (2005)

Newman, L.B.: Friction materials-recent advances. Noyes Data Corporation, Park Ridge (1978)

Littlefield, J.B.: Composition friction element for a railroad brake shoe. US Patent 4313869 (1982)

Shojaei, A., Fahimian, M., Derakhshandeh, B.: Thermally conductive rubber-based composite friction materials for railroad brakes- thermal conduction characteristics. Compos Sci Technol 67, 2665–2674 (2007)

Derakhshandeh, B., Shojaei, A., Faghihi, M.: Effects of rubber curing ingredients and phenolic-resin on mechanical, thermal and morphological characteristics of rubber/phenolic-resin blends. J Appl Polym Sci 108, 3808–3821 (2008)

Dasari, A., Yu, Z.-Z., Mai, Y.-W.: Fundamental aspects and recent progress on wear/scratch damage in polymer nanocomposites. Mater Sci Eng R 63, 31–80 (2009)

Bijwe, J., Nidhi, Majumdar, N., Satapathy, B.K.: Influence of modified phenolic resins on the fade and recovery behavior of friction materials. Wear 259, 1068–1078 (2005)

Dureja, N., Bijwe, J., Gurunath, P.V.: Role of type and amount of resin on performance behavior of non-asbestos organic (NAO) friction materials. J Reinf Plast Compos 28, 489–497 (2009)

Satapathy, B.K., Bijwe, J.: Performance of friction materials based on variation in nature of organic fibres: part Ι. fade and recovery behavior. Wear 257, 573–584 (2004)

Ho, S.C., Chern Lin, J.H., Ju, C.P.: Effect of fibre addition on mechanical and tribological properties of a copper/phenolic-based friction material. Wear 258, 861–869 (2005)

Qu, X., Zhang, L., Ding, H., Liu, G.: The effect of steel fibre orientation on frictional properties of asbestos-free friction materials. Polym Compos 25, 94–101 (2004)

Jang, H., Ko, K., Kim, S.J., Basch, R.H., Fash, J.W.: The effects of metal fibres on the friction performance of automotive brake friction materials. Wear 256, 406–414 (2004)

Satapathy, B.K., Bijwe, J.: Composite friction materials based on organic fibres: sensitivity of friction and wear to operating variables. Composites A 37, 1557–1567 (2006)

Gopal, P., Dharani, L.R., Blum, F.D.: Hybrid phenolic friction composites containing Kevlar® pulp part Ι. Enhancement of friction and wear performance. Wear 193, 199–206 (1996)

Gopal, P., Dharani, L.R., Blum, F.D.: Hybrid phenolic friction composites containing Kevlar® pulp part ΙΙ—wear surface characteristics. Wear 193, 180–185 (1996)

Kim, S.J., Jang, H.: Friction and wear of friction materials containing two different phenolic resins reinforced with aramid pulp. Tribol Int 33, 477–484 (2000)

UIC Code 541-4 OR, International Union of Railways, Brakes with composition brake blocks, 2nd ed. (1990)

Ludema, K.C.: Friction, Wear, Lubrication, 1st edn. CRC Press Inc., Boca Raton (1996)

Shojaei, A., Faghihi, M.: Physico-mechanical properties and thermal stability of thermoset nanocomposites based on styrene-butadiene rubber/phenolic resin blend. Mater Sci Eng A 527, 917–926 (2010)

Herring, J.M.: Mechanism of brake fade in organic brake pad linings. SAE Trans., Paper No. 670146, pp. 558 (1967)

Anderson, A.E.: Friction, lubrication and wear technology. ASM Hand Book, vol. 18, pp. 569–577. ASM Materials Information Society, Materials Park (1990)

Wirth, A., Eggleston, D., Whitaker, R.: A fundamental tribochemical study of the third body layer formed during automotive friction braking. Wear 179, 75–81 (1994)

Sperling, L.H.: Introduction to Physical Polymer Science, 4th edn. Wiley, Hoboken (1990)

Saffar, A., Shojaei, A., Arjmand, M.: Theoretical and experimental analysis of the thermal, fade and wear characteristics of rubber-based composite friction materials. Wear 269, 145–151 (2010)

Neilson, L.E., Landel, R.F.: Mechanical properties of polymers and composites, 2nd edn. Marcel Dekker Inc, New York (1990)

Friedrich, K.: Friction and wear of polymer composites. Elsevier, Amsterdam (1986)

Zhang, M.Q., Rong, M.Z., Luo, Y.: Sliding wear performance of epoxy-based nanocomposites. In: Friedrich, K., Schlarb, A.K. (eds.) Tribology of Polymeric Nanocomposites, Engineering Series, vol. 55, pp. 108–127. Elsevier, Amsterdam (2008)

Acknowledgments

The financial support received from the Iran Railway Research Center is greatly appreciated. All the fillers and reinforcements were donated by Machin-lent-e-Tehran (Iran). The authors are grateful for their kindly support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Arjmand, M., Shojaei, A. Tribological Characteristics of Rubber-Based Friction Materials. Tribol Lett 41, 325–336 (2011). https://doi.org/10.1007/s11249-010-9715-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-010-9715-0