Abstract

During a sliding process, the surface asperities tend to undergo fatigue fracture, break off, and form wear debris. This article applies the principles of continuum damage mechanics (CDM) to predict the appropriate adhesive wear coefficient. Using the CDM approach, we predict the number of cycles before crack nucleation sets in, evaluate the probability that an asperity forms a wear particle, and use this information to derive an expression for the wear coefficient. Experimental wear coefficient results for Aluminum 6061 sliding against stainless steel support the validity of the analytical expression for wear coefficient. A series of results are presented for the variation of wear coefficient as a function of friction coefficient for SAE 4340, Aluminum 6061, Aluminum 2024, and Titanium 6ALV4.

Similar content being viewed by others

Abbreviations

- A :

-

Area of an asperity involved (m2)

- A r :

-

Real area of contact (m2)

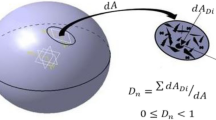

- dA :

-

Elementary area (m2)

- D :

-

Damage variable

- D i :

-

Damage after i cycles

- D c :

-

Critical damage value

- E :

-

Modulus of elasticity of an undamaged material (GPa)

- E′:

-

Effective modulus of elasticity (GPa)

- H :

-

Cyclic hardening modulus (MPa)

- k :

-

Wear coefficient

- k w :

-

Stress-raising effects factor

- L :

-

Normal force (N)

- M :

-

Cyclic hardening exponent

- n :

-

Number of asperities

- n :

-

Normal to an elemental cross section

- N :

-

Number of cycles to failure

- P :

-

Probability of wear particle formation

- p :

-

Material flow pressure (MPa)

- S :

-

Total distance of sliding (m)

- S e :

-

Endurance limit (MPa)

- T i :

-

Boundary traction (MPa)

- V :

-

Wear volume (m3)

- ∆ε oi :

-

Threshold strain of damage increment in cycle i

- ∆εpli :

-

Initial plastic strain in ith cycle

- ∆εpmi :

-

Final plastic strain in ith cycle

- ∆εpoi :

-

Threshold plastic strain of damage increment in cycle i

- ∂R 1 :

-

Part of system boundary on which traction is applied

- ε :

-

Strain

- μ :

-

Friction coefficient

- σ :

-

Stress (MPa)

- σ′ :

-

Effective stress (MPa)

- σ f :

-

True failure stress (MPa)

- σ ∞ :

-

Far-field stress (MPa)

- σ max :

-

Maximum normal stress (MPa)

- τ :

-

Shear stress (MPa)

- ψ D :

-

Partial derivative of Helmholtz free energy with respect to D (MPa)

References

Rabinowicz, E.: Friction and Wear of Materials. Wiley, New York, NY (1995)

Bayer, R.G., Engel, P.A., Sirico, S.L.: Impact wear testing machine. Wear 19, 343–354 (1972)

Halling, J.: Principles of Tribology. Macmillan, London, UK (1975)

Suh, N.P.: Tribophysics. Prentice Hall, Englewood Cliffs, NJ (1986)

Kragelskii, I.V.: Friction and Wear. Butterworths, London, UK (1965)

Rozeanu, L.: Fatigue wear as a rate process. Wear 6, 337–340 (1963)

Kimura, Y.: The role of fatigue in sliding wear. In: Rigney, D.A. (ed.) Fundamentals of Friction and Wear of Materials, pp. 187–219. ASM Materials Science Seminar, Metal Parks, OH (1981)

Arnell, R.D., Davies, P.B., Halling, J., Whomes, T.L.: Tribology: Principles and Design Applications, 1st edn, pp. 11–17. Macmillan, Pittsburgh, PA (1991)

Suh, N.P., Saka, N., Jahanmir, S.: Implications of the delamination theory on wear minimization. Wear 44, 127–134 (1977)

Soda, N., Kimura, Y., Tanaka, A.: Wear of some F.C.C. metals during unlubricated sliding—part IV. Wear 43, 165–174 (1977)

Challen, J.M., Oxley, P.L.B., Hockenhull, B.S.: Prediction of Archard’s wear coefficient for metallic sliding friction assuming a low-cycle fatigue mechanism. Wear 111, 275–288 (1983)

Halling, J.: A contribution to the theory of friction and wear and the relationship between them. Proc. Inst. Mech. Eng. 34, 291–299 (1975)

Yamada, K., Takeda, N., Kagami, J., Naoi, T.: Analysis of the mechanism of steady wear by the fatigue theory as a stochastic process. Wear 54, 217–233 (1979)

Finkin, E.F.: An explanation of the wear of metals. Wear 47, 107–117 (1978)

Jain, V.K., Bahadur, S.: Development of a wear equation for polymer–metal sliding in terms of the fatigue and topography of the sliding surfaces. Wear 60, 237–248 (1980)

Omar, M.K., Atkins, A.G.: The adhesive-fatigue wear of metals. Wear 107, 279–285 (1986)

Archard, J.F.: Contact and rubbing of flat surfaces. J. Appl. Phys. 24, 981–988 (1953)

Archard, J.F., Hirst, W.: The wear of metals under unlubricated conditions. Proc. R. Soc. Lond. Ser. A A236, 397–410 (1956)

Kragelskii, I.V.: Friction and Wear, Calculation Methods. Pergamon Press, London, UK (1982)

Peterson, M.B., Winer, W.O.: Wear Control Handbook. ASME publication, New York, NY (1981)

Fatemi, A., Yang, L.: Cumulative fatigue damage and life prediction theories: a survey of the state of the art for homogeneous materials. Int. J. Fatigue 20(1), 9–34 (1998)

Feinberg, A.A.: Connecting parametric aging to catastrophic failure through thermodynamics. IEEE Trans. Reliab. 45(1), 28–33 (1996)

Bryant, M.D., Khonsari, M.M., Ling, F.F.: On the thermodynamics of degradation. Proc. R. Soc. A 464, 2001–2014 (2008)

Lamaitre, J.: Continuous damage mechanics model for ductile fracture. J. Eng. Mater. Technol. 107(1), 83–89 (1985)

Bhattacharya, B., Ellingwood, B.: A new CDM-based approach to structural deterioration. Int. J. Solids Struct. 36, 1757–1779 (1999)

Hansen, N.R., Schreyer, H.L.: A thermodynamically consistent framework for theories of elastoplasticity coupled with damage. Int. J. Solids Struct. 31(3), 359–389 (1994)

Quraishi, S.M., Khonsari, M.M., Baek, D.K.: A thermodynamic approach for predicting fretting fatigue life. Tribol. Lett. 19(3), 169–175 (2005)

Kachanov, L.M.: On the Creep fracture time. Izv Akad. Nauk USSR Otd. Tekh. 8, 26–31 (1958)

Bhattacharya, B., Ellingwood, B.: Continuum damage mechanics analysis of fatigue crack initiation. Int. J. Fatigue 20(9), 631–639 (1998)

Bhattacharya, B.: A damage mechanics based approach to structural deterioration and reliability. Ph. D. thesis, John Hopkins University, Baltimore, MD (1997)

Krajcinovic, D.: Continuum damage mechanics. Appl. Mech. Rev. 37(1), 1–6 (1984)

Simo, J.C., Ju, J.W.: Strain and stress-based continuum damage models: I. Int. J. Solids Struct. 23(7), 821–840 (1987)

Hult, J.: Introduction and general overview. In: Krajcinovic, D., Lemaitre, J. (eds.) Continuum Damage Mechanics: Theory and Applications, pp. 1–36. Springer, Berlin (1987)

Voyiadjis, G.Z., Kattan, P.I.: Advances in Damage Mechanics: Metals and Metal Matrix Composites, 1st edn. Elsevier, Oxford (1999)

Lamaitre, J.: Engineering Damage Mechanics: Ductile, Creep, Fatigue and Brittle Failures. Springer, Berlin (2005)

Lamaitre, J.: A Course in Damage Mechanics. Springer, New York (1992)

DeVree, J.H.P., Brekelmans, W.A.M., Van Gils, M.A.J.: Comparison of nonlocal approaches in continuum damage mechanics. Comput. Struct. 55(4), 581–588 (1995)

Chow, C.L., Wei, Y.: A damage mechanics model of fatigue crack initiation in notched plates. Theor. Appl. Fract. Mech. 16, 123–133 (1991)

Rosenfield, A.R.: Wear and fracture mechanics. In: Rigney, D.A. (ed.) Fundamentals of Friction and Wear of Materials, pp. 221–234. ASM Materials Science Seminar, Metal Parks, OH (1981)

Nishioka, K., Hirakawa, K.: Fundamental investigations of fretting fatigue—part 2. Bull. JSME 12(50), 180–187 (1969)

Boller, C., Seeger, T.: Materials Data for Cyclic Loading. Elsevier, Amsterdam, The Netherlands (1987)

Endo, T., Morrow, J.: Cyclic stress–strain and fatigue behavior of representative aircraft metals. J. Mater. (JMLSA) 4(1), 159–175 (1969)

Wong, W.A.: Monotonic and Cyclic Fatigue Properties of Automotive Aluminum Alloys. Kaiser Aluminum & Chemical Corp, Pleasanton, CA (1984)

Baumel Jr., A., Seeger, T.: Materials Data for Cyclic Loading, Supplement 1. Elsevier, Amsterdam (1990)

Amiri, M., Naderi, M., and Khonsari, M. M.: An experimental approach to evaluate the critical damage. Int. J. Damage Mech. doi:10.1177/1056789509343082 (2010)

Ming, Q., Yougzhen, Z., Jun, Z., Jianheng, Y.: Dry friction characteristics of Ti-6Al-4V alloy under high sliding velocity. J. Wuhan Univ. Technol. 22(4), 582–585 (2007)

Niebuhr, D.: Friction and wear behavior of engineering materials in a simulated Martian (CO2) environment, a preliminary study. Wear 263, 88–92 (2007)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Beheshti, A., Khonsari, M.M. A Thermodynamic Approach for Prediction of Wear Coefficient Under Unlubricated Sliding Condition. Tribol Lett 38, 347–354 (2010). https://doi.org/10.1007/s11249-010-9614-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-010-9614-4