Abstract

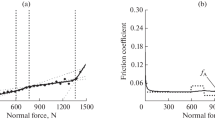

The friction and wear of a pure copper block (99.98 wt% Cu) against a hardened steel disc were studied. The effect of sliding velocity and load on the friction coefficient and wear rate of Cu samples during steady tests was studied. Elasto-hydrodynamic (EHL), mixed (ML) and boundary lubrication (BL) regions were analyzed using the Stribeck curve. The lubrication number of Schipper, Z, was used in the analysis of the Stribeck curve. The transitions from one lubrication region to another are discussed. The mixed EHL region is characterized by stable low values of the friction coefficient, wear rate and temperature. Straight asperity contact is the dominant mechanism under friction of Cu–steel pair in the BL region. High-friction coefficients and wear rates, thin lubricant films and large wear grooves indicate straight asperity contact between rubbed surfaces in the BL region. Although the dominant mechanisms in the mixed EHL and BL regions are different in principle, a steady friction state is preserved in both cases. It is expected that the steady friction state in the BL and mixed EHL regions is associated with deformation and fracture of surface layers but these process occur at different scale levels. It was shown that under friction of Cu–steel pair, two types of ML regions are observed. The first is the stable steady friction of mixed EHL with low values of the friction coefficient and wear rate. The second type of the ML region is the region of unstable friction and wear when a decrease of lubricant film leads to a change of external (roughness, temperature, friction and wear) and internal (strain and stress) parameters. It was found out that a transition to the unstable ML region occurs within a narrow range of Z parameter under definite values of the load and sliding velocity.

Similar content being viewed by others

References

Rigney, D.: Large strains associated with sliding contact of metals. Mater. Res. Innov. 1, 231–234 (1998)

Rapoport, L., Parshutin, V., Petrov, Yu.: The influence of temperature on the deformation and fracture of LiF single crystal subjected to friction and wear. Wear 116, 225–236 (1987)

Mishra, A., Kad, B.K., Gregory, F., Meyers, M.A.: Microstructural evaluation in copper subjected to severe plastic deformation: experimental and analysis. Acta Mater. 55, 13–28 (2007)

Gubicza, J., Chinh, N.Q., Csanadi, T., Lagdon, T.G., Ungar, T.: Microstructure and strength of severely deformed fcc metals. Mater. Sci. Eng. A 462, 86–90 (2007)

Zhang, Y.S., Han, Z., Wang, K., Lu, K.: Friction and wear of nanocrystalline surface layer of pure copper. Wear 260, 942–948 (2006)

Stribeck, R.: Characteristics of plain and roller bearings. Zeit. Ver. Deutsch. Ing. 46, 1341–1348, 1432–1438, 1463–1470 (1902)

Hersey, M.D.: Theory and Research in Lubrication. Wiley, New York (1966)

Gelinck, E.R.M., Schipper, D.J.: Calculation of Stribeck curves for line contacts. Tribol. Int. 33, 175–181 (2000)

Spikes, H.A., Olver, A.V.: Basics of mixed lubrication. In: Proceedings of 13th International Colloquium on Lubricant, Materials and Lubrication Engineering, Esslingen, pp. 19–30 (2003)

Chang, L.: A deterministic model for line contact partial elastohydrodynamic lubrication. Tribol. Int. 28, 75–84 (1995)

Lu, X., Khonsari, M.M., Gelinck, E.R.M.: The Stribeck curve: experimental results and theoretical prediction. ASME Tribol. Int. 128, 789–794 (2006)

Kapoor, A., Johnson, K.L.: Plastic ratcheting as a mechanism of metallic wear. Proc. R. Soc. Lond. A 445, 367–381 (1994)

Kapoor, A.: Wear by plastic ratcheting. Wear 212, 119–130 (1997)

Rapoport, L.: Steady friction state and contact models of asperity interaction. Wear 267, 1305–1310 (2009)

Campbell, W.E.: Boundary lubrication. In: Ling, F.F., Klaus, E.E., Fein, R.S. (eds.) Boundary lubrication, an appraisal of world literature, pp. 87–117. ASME, New York (1969)

Williams, J.: Advances in the modeling of boundary lubrication. In: Dowson, D. (ed.) Boundary and Mixed Lubrication: Science and Applications, pp. 37–48. Elsevier Science, Amsterdam (2002)

Hamrock, B.: Fundamentals of Fluid Film Lubrication. Mechanical Engineering Series. McGraw-Hill International, New York (1994)

Bongaerts, J.H., Fourtouni, K., Stokes, J.R.: Soft-tribology: lubrication in a compliant PDMS-PDMS contact. Tribol. Int. 40, 1531–1542 (2007)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Moshkovich, A., Perfilyev, V., Lapsker, I. et al. Stribeck Curve Under Friction of Copper Samples in the Steady Friction State. Tribol Lett 37, 645–653 (2010). https://doi.org/10.1007/s11249-009-9562-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-009-9562-z