Abstract

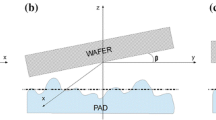

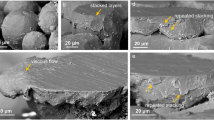

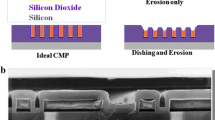

An asperity-scale wear model was developed to predict feature-scale wear in chemical–mechanical polishing (CMP), and was compared to the measured evolution of a lithographically patterned feature during full-scale CMP tests. To conduct this study, a lithographic technique was used to pattern a set of raised square features into a Cu-coated silicon wafer. Two-dimensional contact profilometry was used to measure the topography of an isolated feature on each wafer both before polishing and at various intervals throughout the polishing process. In the wear modeling formulation, a pad deflection-based contact mechanics model was developed and combined with a particle-based wear model to predict the wear evolution of the sample during CMP. The predicted wear of the sample feature was found to agree well to experimental results.

Similar content being viewed by others

References

Terrell, E.J., Higgs, C.F.: Hydrodynamics of slurry flow in chemical mechanical polishing—a review. J. Electrochem. Soc. 153(6), K15–K22 (2006)

Haosheng, C., Jiang, L., Darong, C., Jiadao, W.: Nano particles’ behavior in non-Newtonian slurry in mechanical process of CMP. Tribol. Lett. 24(3), 179–186 (2006)

Terrell, E.J., Higgs, C.F.: A modeling approach for predicting the abrasive particle motion during chemical mechanical polishing. J. Tribol. 129(4), 933–941 (2007)

Terrell, E.J., Higgs, C.F.: A particle-augmented mixed lubrication modeling approach to predicting chemical mechanical polishing. J. Tribol. 131(1), 012201 (10 pp) (2009)

Nanz, G., Camilletti, L.E.: Modeling of chemical–mechanical polishing—a review. IEEE Trans. Semicond. Manuf. 8(4), 382–389 (1995)

Zantye, P.B., Kumar, A., Sikder, A.K.: Chemical mechanical planarization for microelectronics applications. Mater. Sci. Eng. R 45(3–6), 132 (2004)

Zabasajja, J., Merchant, T., Ng, B., Banerjee, S., Green, D., Lawing, S., Kura, H.: Modeling and characterization of tungsten chemical and mechanical polishing processes. J. Electrochem. Soc. 148(2), G73–G77 (2001)

Paul, E., Kaufman, F., Brusic, V., Zhang, J., Sun, F., Vacassy, R.: A model of copper CMP. J. Electrochem. Soc. 152(4), G322–G328 (2005)

Jeng, Y.R., Huang, P.Y.: A material removal rate model considering interfacial micro-contact wear behavior for chemical mechanical polishing. J. Tribol. 127(1), 190–197 (2005)

Jeng, Y.R., Huang, P.Y.: Impact of abrasive particles on the material removal rate in CMP—a microcontact perspective. Electrochem. Solid State Lett. 7(2), G40–G43 (2004)

Luo, J.F., Dornfeld, D.A.: Material removal mechanism in chemical mechanical polishing: theory and modeling. IEEE Trans. Semicond. Manuf. 14(2), 112–133 (2001)

Castillo-Mejia, D., Beaudoin, S.: A locally relevant wafer-scale model for CMP of silicon dioxide. J. Electrochem. Soc. 150(9), G581–G586 (2003)

Mazaheri, A.R., Ahmadi, G.: Modeling the effect of bumpy abrasive particles on chemical mechanical polishing. J. Electrochem. Soc. 149(7), G370–G375 (2002)

Che, W., Guo, Y.J., Chandra, A., Bastawros, A.: A scratch intersection model of material removal during chemical mechanical planarization (CMP). J. Manuf. Sci. Eng. 127(3), 545–554 (2005)

Zhao, Y.W., Chang, L.: A micro-contact and wear model for chemical–mechanical polishing of silicon wafers. Wear 252(3–4), 220–226 (2002)

Zeng, T.F., Sun, T.: Size effect of nanoparticles in chemical mechanical polishing—a transient model. IEEE Trans. Semicond. Manuf. 18(4), 655–663 (2005)

Fu, G.H., Chandra, A., Guha, S., Subhash, G.: A plasticity-based model of material removal in chemical–mechanical polishing (CMP). IEEE Trans. Semicond. Manuf. 14(4), 406–417 (2001)

Shi, F.G., Zhao, B.: Modeling of chemical–mechanical polishing with soft pads. Appl. Phys. A 67(2), 249–252 (1998)

Gutmann, R.J., Steigerwald, J.M., You, L., Price, D.T., Neirynck, J., Duquette, D.J., Murarka, S.P.: Chemical–mechanical polishing of copper with oxide and polymer interlevel dielectrics. Thin Solid Films 270(1–2), 596–600 (1995)

Tang, B.D., Xie, X.L., Boning, D.S.: Damascene chemical–mechanical polishing characterization and modeling for polysilicon microelectromechanical systems structures. J. Electrochem. Soc. 152(7), G582–G587 (2005)

Chekina, O.G., Keer, L.M., Liang, H.: Wear-contact problems and modeling of chemical mechanical polishing. J. Electrochem. Soc. 145(6), 2100–2106 (1998)

Chang, R.Z., Cao, Y., Spanos, C.J.: Modeling the electrical effects of metal dishing due to CMP for on-chip interconnect optimization. IEEE Trans. Electron Devices 51(10), 1577–1583 (2004)

Saxena, R., Thakurta, D.G., Gutmann, R.J., Gill, W.N.: A feature scale model for chemical mechanical planarization of damascene structures. Thin Solid Films 449(1–2), 192 (2004)

Nguyen, P.H., Bar, E., Lorenz, J., Ryssel, H.: Modeling of chemical–mechanical polishing on patterned wafers as part of integrated topography process simulation. Microelectron. Eng. 76(1–4), 89–94 (2004)

Sawyer, W.G.: Surface shape and contact pressure evolution in two component surfaces: application to copper chemical mechanical polishing. Tribol. Lett. 17(2), 139–145 (2004)

Yao, C.H., Feke, D.L., Robinson, K.M., Meikle, S.: Modeling of chemical mechanical polishing processes using a discretized geometry approach. J. Electrochem. Soc. 147(4), 1502–1512 (2000)

Yao, C.-H., Feke, D.L., Robinson, K.M., Meikle, S.: Influence of feature-scale surface geometry on CMP processes. J. Electrochem. Soc. 147(8), 3094 (2000)

Castillo-Mejia, D., Beaudoin, S.: A locally relevant Prestonian model for wafer polishing. J. Electrochem. Soc. 150(2), G96–G102 (2003)

Luo, Q., Ramarajan, S., Babu, S.V.: Modification of the Preston equation for the chemical–mechanical polishing of copper. Thin Solid Films 335(1–2), 160–167 (1998)

Steigerwald, J.M., Zirpoli, R., Murarka, S.P., Price, D., Gutmann, R.J.: Pattern geometry-effects in the chemical–mechanical polishing of inlaid copper structures. J. Electrochem. Soc. 141(10), 2842–2848 (1994)

Lai, J.Y., Saka, N., Chun, J.H.: Evolution of copper-oxide damascene structures in chemical mechanical polishing—II. Copper dishing and oxide erosion. J. Electrochem. Soc. 149(1), G41–G50 (2002)

Chen, Z., Sun, F., Vacassy, R.: An empirical dielectric erosion formula in metal chemical mechanical planarization. J. Electrochem. Soc. 153(6), G582–G586 (2006)

Kazimi, S.M.A.: Solid Mechanics. Tata McGraw-Hill, New Delhi (1981)

Mpagazehe, J., Thukalil, G., Higgs, C.F.: A study to estimate the number of active particles in CMP. In: Materials Research Society Proceedings, San Francisco, CA, 13–17 April 2009

Tichy, J., Levert, J.A., Shan, L., Danyluk, S.: Contact mechanics and lubrication hydrodynamics of chemical mechanical polishing. J. Electrochem. Soc. 146(4), 1523–1528 (1999)

Shan, L., Levert, J., Meade, L., Tichy, J., Danyluk, S.: Interfacial fluid mechanics and pressure prediction in chemical mechanical polishing. J. Tribol. 122(3), 539–543 (2000)

Guo, L., Subramanian, R.S.: Mechanical removal in CMP of copper using alumina abrasives. J. Electrochem. Soc. 151(2), 104–108 (2004)

Steigerwald, J.M., Murarka, S.P., Ho, J., Gutmann, R.J., Duquette, D.J.: Mechanisms of copper removal during chemical mechanical polishing. J. Vac. Sci. Technol. B 13(6), 2215–2218 (1995)

Lin, J.F., Chen, S.-C., Ouyang, Y.L., Tsai, M.S.: Analysis of the tribological mechanisms arising in the chemical–mechanical polishing of copper-film wafers when using a pad with concentric grooves. J. Tribol. 128, 445–459 (2006)

Figliola, R.S., Beasley, D.E.: Theory and Design for Mechanical Measurements. Wiley, Hoboken (2005)

Acknowledgments

The authors would like to thank the Alfred P. Sloan Foundation, the Pittsburgh Infrastructure Technology Alliance, and the NSF CAREER Program for their support of this research. Additionally, the authors are grateful for the support of the PPG Industries, for supplying polishing pads, and Advanced MicroSensors, for supplying the wafers that were used for this research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Terrell, E.J., Comes, R.B. & Higgs, C.F. Analysis of Feature-Scale Wear in Chemical Mechanical Polishing: Modeling and Experiments. Tribol Lett 37, 327–336 (2010). https://doi.org/10.1007/s11249-009-9524-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-009-9524-5