Abstract

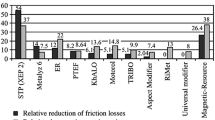

It is well known that the presence of soot in engine oils can lead to an increase in wear of engine parts. This is a growing problem as soot levels in diesel engine oils are rising due to a combination of extended drain intervals and the various methods employed to reduce NO x formation such as retarded ignition and exhaust gas recirculation. Several different mechanisms have been proposed by which soot might lead to an increase in wear in mixed lubrication conditions, of which the most widely favoured is abrasion by soot, either of the rubbing metallic parts in engines or of the antiwear additive films formed on rubbing metal surfaces. In this study it is shown that the combination of mixed alkyl ZDDP and carbon black (used as soot surrogate) is strongly antagonistic in terms of wear. In a lubricant containing carbon black, the presence of ZDDP leads to considerably more wear than if ZDDP is left out. A similar, though less severe antagonism is also seen with primary ZDDP and other antiwear and EP additives. By varying the lubricant film thickness it is shown that the effect of carbon black in ZDDP-containing oils is to promote wear up to quite thick hydrodynamic film conditions, approaching the secondary carbon black particle size. It is proposed that the antagonistic wear effect results from a corrosion-abrasive mechanism in which the reaction film formed by antiwear additive and rubbing metal surface is very rapidly and continually abraded by carbon black. At most carbon black concentrations, wear rate then becomes controlled by the rate of initial antiwear additive film formation, which for secondary ZDDP is very rapid, rather than by the kinetics of the abrasive process. From this understanding, strategies for reducing the impact of engine soot on wear can be deduced.

Similar content being viewed by others

References

Ratoi, M., Castle, R., Bovington, C., Spikes, H.A.: Influence of soot and dispersant on ZDDP film thickness and friction. Lubr. Sci. 17, 25–43 (2004)

Rounds, F.G.: Carbon: cause of diesel engine wear. SAE Paper 770829 (1978)

Rounds, F.G.: Effect of lubricant additives on the prowear characteristics of synthetic diesel soot. Lubr. Eng. 43, 273–282 (1987)

Diatto, P., Anzani, M., Tinucci, L., Tripaldi, G., Vettor, A.: Investigation on soot dispersant properties and wear effects in the boundary lubrication regime. In: Dowson, D. et al. (ed.) Proceedings of the 25th Leeds-Lyon Symposium on Tribology, Lubrication at the Frontier, Elsevier, Amsterdam (1999)

Hirose, Y.: Deterioration and wear characteristics of diesel engine oil. J. Jpn Soc. Lubr. Eng. 27, 394–395 (1982)

Berbezier, I., Martin, J.M., Kapsa, Ph.: The role of carbon in lubricated mild wear. Tribol. Int. 19, 115–122 (1986)

Corso, S., Adamo, R.: The effect of diesel soot on reactivity of oil additives and valve train materials. SAE Paper 841369 (1984)

Akiyama, K., Masunaga, K., Kado, K., Yoshioka, T.: Cylinder wear mechanism in an EGR-equipped diesel engine and wear protection by the engine oil. SAE Paper 872158 (1987)

Cusano, C., Sliney, H.E.: Dynamics of solid dispersions in oil during the lubrication of point contact. Part I-Graphite. ASLE Trans. 25, 183–189 (1982)

Colacicco, P., Mazuyer, D.: The role of soot aggregation on the lubrication of diesel-engines. Tribol. Trans. 38, 959–965 (1995)

Yoshida, K.: Effects of sliding speed and temperature on tribological behavior with oils containing a polymer additive or soot. Tribol. Trans. 33, 221–228 (1990)

Ryason, P.R., Chan, I.Y., Gilmore, J.T.: Polishing wear by soot. Wear 137, 15–24 (1990)

Bardasz, E.A., Carrick, V.A., Ebeling, V.I., George, H.F., Graf, M.M., Kornbrekke, R.E., Pocinki, S.B.: Understanding soot mediated oil thickening through designed experimentation—Part 2: GM 6.5L. SAE Paper 961915 (1996)

Yahagi, Y.: Corrosive wear of diesel engine cylinder bore. Tribol. Int. 20, 365–373 (1987)

Nagai, I., Endo, H., Nakamura, H., Yano, H.: Soot and valve wear in passenger car diesel engine. SAE Paper 831757 (1983)

Mainwaring, R.: Soot and wear in heavy duty diesel engines. SAE Paper 971631 (1997)

Van Dam, W., Willis, W.W., Cooper, M.W.: The impact of additive chemistry and rheology on wear in heavy duty diesel engines. SAE Paper 1999-01-3575 (1999)

Hosonuma, K., Yoshida, K., Matsunaga, A.: The decomposition products of zinc dialkyldithiophosphate in an engine oil and their interactions with diesel soot. Wear 103, 297–309 (1985)

Kawamura, M., Ishiguro, T., Fujita, K., Morimoto, H.: Deterioration of antiwear properties of diesel engine oils during use. Wear 123, 269–280 (1988)

Gautam, M., Chitoor, K., Durbha, M., Summers, J.C.: Effect of soot contaminated oil on engine wear–investigation of novel oil formulations. Tribol. Int. 32, 687–699 (1999)

Mowlem, J.K., Edwards, J.C.: Lubricant additive chemistry effects of diesel engine soot on wear performance as studied by XPS and solid-state NMR. http://www.process-nmr.com/pdfs/Diesel%20Engine%20Soot%20Study.pdf (2002). Accessed 20 Jan 2009

Hirose, Y., Kunoki, T., Kawashima, K., Kanai, S., Hirami, K.: Development of a new multigrade engine oil for improving wear resistance in heavy vehicle diesel engines—part I: diesel soot and valve train wear. SAE Technical Paper 852134 (1885)

Cadman, W., Johnson, J.H.: The study of the effect of exhaust gas recirculation on engine wear in a heavy-duty diesel engine using analytical ferrography. SAE Paper 860378 (1986)

Needelman, W. M., Madhavan, P. V.: Review of lubricant contamination and diesel engine wear. SAE Paper 881827, (1988)

Narita, K.: The effects of diesel soot on engine oil performance. Jpn J. Tribol. 42, 677–683 (1997)

Jao, T.-C., Li, S., Yatasumi, K., Chen, S.J., Csontos, A.A., Howe, J.M.: Soot characterisation and diesel engine wear. Lubr. Sci. 16, 111–126 (2004)

Fujita, H., Spikes, H.A.: The influence of soot on lubricating films. In: Dalmaz, G., et al. (ed.) Proceedings of the 30th Leeds-Lyon Tribology Symposium, Transient Processes in Tribology, pp. 37–43, Elsevier, Amsterdam (2004)

Booth, J.E., Nelson, K.D., Harvey, T.J., Wood, R.J.K., Wang, L., Powrie, H.E.G., Martinez, J.G.: The feasibility of using electrostatic monitoring to identify diesel lubricant additives and soot contamination interactions by factorial analysis. Tribol. Int. 39, 1564–1575 (2006)

Johnston, G.J., Wayte, R., Spikes, H.A.: The measurement and study of very thin lubricant films in concentrated contacts. Tribol. Trans. 34, 187–194 (1991)

Topolovec-Miklozic, K., Forbus, T.R., Spikes, H.A.: Film thickness and roughness of ZDDP antiwear films. Tribol. Lett. 26, 161–171 (2007)

Smeeth, M., Spikes, H.A.: The influence of slide/roll ratio on the film thickness in EHD contact operating in the mixed lubrication regime. In Dowson, D., et al. (ed.) Proceedings of the 22nd Leeds/Lyon Symposium on Tribology, The Third Body Concept: Interpretation of Tribological Phenomena, pp. 695–703, Elsevier, Amsterdam (1996)

Fujita, H., Glovnea, R.P., Spikes, H.A.: The study of zinc dialkyldithiophosphate anti-wear film formation and removal process. Part I: Experimental. Tribol. Trans. 48, 558–566 (2005)

Stachowiak, G.W., Batchelor, A.W.: Engineering tribology, 2nd edn, Chapter 13, Corrosive and Oxidative Wear, Butterworth Heinmann, Boston (2001)

Aktary, M., McDermott, M.T., McAlpine, G.A.: Morphology and nanomechanical properties of ZDDP antiwear films as a function of tribological contact time. Tribol. Lett. 12, 155–162 (2002)

Carraher Jr., C.E.: General topics: carbon black. Polym. News 29, 122–123 (2004)

Yamamoto, H., Yamakawa, S., Kato, T.: Research on hardness of soot contaminated diesel engine oil. Nihon. Kikai. Gakkai. Taikan. Koen. Ronbushi. 3, 137–138 (2003)

Beshouri, G.M.: Lubricant additive effects on cam and tappet wear in medium speed diesel engines. SAE Paper 860377 (1986)

Yoshihara, T., Wakizono, T., Hara, H., Nakagawa, E.: Effects of engine oil additives on valve train wear of diesel engines. SAE Paper 831759 (1983)

Yamaguchi, E.S., Ryason, P.R., Hansen, T.P.: Electrical contact resistance studies of zinc dialkyldithiophosphates. Tribol. Lett. 3, 27–33 (1997)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Olomolehin, Y., Kapadia, R. & Spikes, H. Antagonistic Interaction of Antiwear Additives and Carbon Black. Tribol Lett 37, 49–58 (2010). https://doi.org/10.1007/s11249-009-9489-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-009-9489-4