Abstract

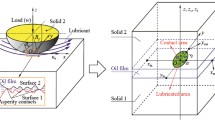

The classical ElastoHydroDynamic (EHD) theory assumes a Newtonian lubricant and an isothermal operating regime. In reality, lubricating oils do not behave as perfect Newtonian fluids. Moreover, in most operating conditions of an engineering system, especially at high speeds, thermal effects are important and temperature can no longer be considered as constant throughout the system. This is one reason why there has always been a gap between numerical results and experimental data. This paper aims to show that this gap can be reduced by taking into consideration the heat generation that takes place in the contact and using appropriate rheological models. For this, a unique thermal ElastoHydrodynamic lubrication model is developed for both Newtonian and non-Newtonian lubricants. Pressure, film thickness and traction results are then compared to their equivalent isothermal results and experimental data. The agreement between thermal calculations and experiments reveals the necessity of considering thermal effects in EHD models.

Similar content being viewed by others

Abbreviations

- ρ :

-

Lubricant’s density

- η :

-

Generalized Newtonian viscosity

- μ :

-

Newtonian viscosity

- H :

-

Film thickness

- p :

-

Pressure

- p h :

-

Hertzian contact pressure

- a :

-

Hertzian contact radius

- x,y,z :

-

Space coordinates

- U m :

-

Mean entrainment velocity

- U :

-

Elastic displacement vector (U = {u, v, w})

- L :

-

Load

- u i :

-

Surface velocity of body i

- u f, v f :

-

Fluid flow velocity components in the x- and y-directions, respectively

- h 0 :

-

Film thickness equation constant

- R :

-

Ball’s radius

- σ:

-

Stress tensor

- ɛ:

-

Strain tensor

- C :

-

Compliance matrix

- T :

-

Temperature

- T 0 :

-

Ambient temperature

- T R :

-

Reference temperature

- c i :

-

Heat capacity of body i

- ρ i :

-

Density of body i

- k i :

-

Thermal conductivity of body i

- E i :

-

Young’s modulus of body i

- υ i :

-

Poisson’s ratio of body i

- x in :

-

Inlet abscissa of the contact

- p + :

-

Positive part of the pressure distribution

- μ 0 :

-

Lubricant’s zero pressure Newtonian viscosity

- ρ 0 :

-

Lubricant’s zero pressure density

- SRR:

-

Slide-to-roll ratio = 2(u s − u p )/(u s + u p )

- H c :

-

Central film thickness

- H min :

-

Minimum film thickness

- \(H_{c_{\rm min}}\) :

-

Minimum film thickness on the central line of the contact in the x-direction

- K 0,K ′0 ,B,R 0 :

-

Tait-Doolittle model constants

- G c,n c :

-

Carreau equation constants

- μ1,μ2 :

-

Low-shear and high-shear limiting viscosities, respectively

- β K ,ɛ c ,a V :

-

Tait-Doolittle model constants

- DT :

-

Temperature variation = T−T 0

- M, L :

-

Dimensionless Moes–Venner parameters \( \begin{array}{l} P=\frac{p}{p_{\rm h}}\quad \bar{{\rho}}=\frac{\rho}{\rho_0} \quad \bar{{\mu}}=\frac{\mu }{\mu _0 }\quad H=\frac{hR}{a^{2}}\\ X=\frac{x}{a}\quad Y=\frac{y}{a}\quad Z=\left\{ {\begin{array}{l} \frac{z}{a}\hbox{:Solids p and s}\\ \frac{z}{h}\hbox{:Lubricant}\\ \end{array}} \right.\\ \end{array} \)

References

Cheng, H.S., Sternlicht, B.: A numerical solution for the pressure, temperature and film thickness between two infinitely long, lubricated rolling and sliding cylinders, under heavy loads. ASME J. Basic Eng. 87, 695–707 (1965)

Cheng, H.S.: A refined solution to the thermal-elastohydrodynamic lubrication of rolling and sliding cylinders. ASLE Trans 8, 397–410 (1965)

Zhu, D., Wen, S.: A full numerical solution for the thermo-elastohydrodynamic problem in elliptical contacts. ASME J. Tribol. 106, 246–254 (1984)

Kim, K.H., Sadeghi, F.: Three-dimensional temperature distribution inEHD lubrication: Part I—circular contact. ASME J. Tribol. 114, 32–41 (1992)

Guo, F., Yang, P., Qu, S.: On the theory of thermal elastohydrodynamic lubrication at high slide-roll ratios—circular glass-steel contact solution at opposite sliding. ASME J. Tribol. 123, 816–821 (2001)

Liu, X., Jiang, M., Yang, P., Kaneta, M.: Non-Newtonian thermal analyses of point EHL contacts using the eyring model. ASME J. Tribol. 127, 70–81 (2005)

Kim, H.J., Ehret, P., Dowson, D., Taylor, C.M.: Thermal elastohydrodynamic analysis of circular contacts, Part 1: Newtonian model. IMechE J. Eng. Tribol. 215(J), 339–352 (2001)

Eyring, H.: Viscosity, plasticity and diffusion as examples of absolute reaction rates. J. Chem. Phys. 4, 283–291 (1936)

Barus, C.: Isothermals, isopiestics and isometrics relative to viscosity. Am. J. Sci. 45, 87–96 (1893)

Roelands, C.J.A.: Correlational Aspects of the viscosity-temperature-pressure relationship of lubricating oils. PhD thesis, Technische Hogeschool Delft, The Netherlands (1966)

Dowson, D., Higginson, G.R.: Elastohydrodynamic Lubrication. The Fundamental of Roller and Gear Lubrication. Pergamon, Oxford (1966)

Yang, P., Wen, S.: A generalized Reynolds equation for non-Newtonian thermal elastohydrodynamic lubrication. ASME J. Tribol. 112, 631–636 (1990)

Carreau, P.J.: Rheological equations from molecular network theories. Trans. Soc. Rheol. 16(1), 99–127 (1972)

Reynolds, O.: On the theory of the lubrication and its application to Mr Beauchamp Tower’s experiments, including an experimental determination of the viscosity of olive oil. Philos. Trans. R. Soc. 177, 157–234 (1886)

Habchi, W., Eyheramendy, D., Vergne, P., Morales-Espejel, G.: A full-system approach of the elastohydrodynamic line/point contact problem. ASME J. Tribol. 130(2), (2008, to appear)

Brooks, A.N., Hughes, T.J.R.: Streamline-upwind/Petrov-Galerkin formulations for convective dominated flows with particular emphasis on the incompressible Navier-Stokes equations. Comp. Methods Appl. Mech. Eng. 32, 199–259 (1982)

Bair, S.: High-Pressure Rheology for Quantitative Elastohydrodynamics. Elsevier Science, Amsterdam (2007)

Cook, R.L., King, H.E., Herbst, C.A., Herschback, D.R.: Pressure and temperature dependent viscosity of two glass forming liquids: glycerol and dibutyl phthalate. J. Chem. Phys. 100(7), 5178–5189 (1994)

Bridgman, P.W.: The Physics of High Pressure. Dover, New York (1970)

Lide, D.R.: CRC Handbook of Chemistry and Physics, 85th edn. CRC press, Boca Raton-Florida (2004)

Hirschfelder, J.O., Curtiss, C.F., Bird, R.B.: Molecular Theory of Gases and Liquids. Wiley, New York (1954)

Hogenboom, D.L., Webb, W., Dixon, J.D.: Viscosity of several liquid hydrocarbons as a function of temperature, pressure and free volume. J. Chem. Phys. 46(7), 2586–2598 (1967)

Doolittle, A.K.: Studies in Newtonian flow II, the dependence of the viscosity of liquids on free-space. J. Appl. Phys. 22, 1471–1475 (1951)

Bair, S.: A rough shear-thinning correction for EHD film thickness. STLE Tribol. Trans. 47, 361–365 (2004)

Habchi, W., Demirci, I., Eyheramendy, D., Morales-Espejel, G., Vergne, P.: A finite element approach of thin film lubrication in circular EHD contacts. Tribol. Int. 40, 1466–1473 (2007)

Jubault, I., Molimard, J., Lubrecht, A.A., Mansot, J.L., Vergne, P.: In situ pressure and film thickness measurements in rolling/sliding lubricated point contacts. STLE Tribol. Lett. 15(4), 421–429 (2003)

Acknowledgements

The authors thank Prof. E. Ioannides (SKF Group Technical Director) for his kind permission to publish this work. They also wish to express their gratitude to the French Ministry of National Education and Scientific Research for partially financing this study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Habchi, W., Eyheramendy, D., Bair, S. et al. Thermal Elastohydrodynamic Lubrication of Point Contacts Using a Newtonian/Generalized Newtonian Lubricant. Tribol Lett 30, 41–52 (2008). https://doi.org/10.1007/s11249-008-9310-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-008-9310-9