Abstract

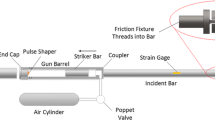

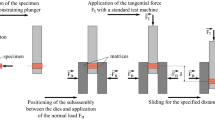

A dynamic tribometer has been successfully developed utilizing torsional Kolsky bar (TKB) technique for tribo pairs subjected to dynamic compression and shear. The dynamic tribometric responses of ground finish (R a = 0.17 μm) and polished finish (R a = 0.10 μm) surfaces of silicon carbide (SiC) under compression loading up to 1.5 GPa and shear-sliding velocity to 3.8 m/s have been measured. The experimental results show Coulomb friction behavior. Hardening of shear response is found on both the ground and polished surfaces. Repeating tests on the same tribo-pair demonstrate that steady state shear response on polished surfaces can be achieved by cumulating shear-sliding distance. SEM observation of the tested surface shows that the tested surfaces are microscopically shear-damaged. The similar surface conditions after a relative longer shear-sliding distance on polished surfaces lead to the same steady state frictional coefficient, 0.61, for both finishing surfaces.

Similar content being viewed by others

References

Yust, G.S., Carignan, F.J.: Observations on the sliding wear of ceramics. ASLE Trans. 28, 245–252 (1985)

Ishigaki, H., Kawaguchi, I., Iwasa, M., Toibana, Y.: Friction and wear of hot pressed silicon nitride and other ceramics. J. Tribology 108, 514–521 (1986)

Bahadur, S., Iskandar, I.: Effect of test variables on the friction and wear of alumina. Wear testing of advanced materials, ASTM STP 1167 7–23. In: Divakar, R., Blau, P. J. (eds.) Am. Soc. For Testing and Mater., Philadelphia (1992)

Kitaoka, S., Tsuji, T., Katoh, T., Yamaguchi, Y., Kashiwagi, K.: Tribological characteristics of SiC ceramics in high-temperature and high-pressure water. J. Am. Ceram. Soc. 77, 1851–1856 (1994)

Senda, T., Yasuda, E., Kaji, M., Bradt, R.C.: Effect of grain size on the sliding wear and friction of alumina at elevated temperatures. J. Am. Ceram. Soc. 82, 1505–1511(1999)

Cho, S., Um, C.: Wear and wear transition in silicon carbide ceramics during sliding. J. Am. Ceram. Soc. 79, 1247–1251 (1996)

Hisakado, T.: Wear mechanism of ceramics and gut face topography. J. Tribology 108, 9–15 (1986)

Huang, H., Feng, R.: A study of the dynamic tribological response of closed fracture surface pairs by Kolsky-bar compression-shear experiment. Int. J. of Solids. Struct. 41, 2821–2835 (2004)

Hartley, K.A., Duffy, J., Hawley, R.H. The torsional Kolsky (split-Hopkinson) bar. ASM Metals Handbook, 43, pp. 218–228. ASM International, Metals Park, Ohio (1985)

Chichili, R.D., Ramesh, K.T.: Recovery experiments for adiabatic shear localization: A novel experimental technique. J. Appl. Mech. 66, 10–20 (1999)

Ogawa, K.: Impact friction test method by applying stress waves. Exp. Mech. 37, 398–402 (1997)

Rajagopalan, S., Prakash, V.: A modified torsional Kolsky bar for investigating dynamic friction. Exp. Mech. 39, 295–303 (1999)

Espinosa, H.D., Patanella, A., Fisher, M.: A novel dynamics friction experiment using a modified Kolsky bar apparatus. Exp. Mech. 40, 138–153 (2000)

Achenbach, J. D.: Wave propagation in elastic solids. North-Holland, Amsterdam (1975)

Davies, E.D.H., Hunter, S.C.: The dynamic compression testing of solids by the method of the split Hopkinson pressure bar. J. Mech. Phys. Solids. 11, 155–179 (1963)

Lindholm, U.S.: Some experiments with the split Hopkinson pressure bar. J. Mech. Phys. Solids. 12, 317–335 (1964)

Tucci, A., Esposito, L.: Second phases and material transfer in alumina ceramics sliding systems. Wear 245, 76–83 (2000)

Pasaribu, H.R., Sloetjes, J.W., Schipper, D.J. Friction reduction by adding copper oxide into alumina and zirconia ceramics. Wear 255, 699–707 (2003)

Bhushan, B., Gupta, B.K.: Handbook of tribology: Materials, coatings, and surface treatments. McGraw-Hill, Inc., New York (1991)

Robinowicz, E.: The intrinsic variables affecting the stick-slip process. Proc. Phys. Soc. London 71, 668–675 (1958)

Dieterich, J.H.: Modeling of rock friction: 2. Simulation of preseismic slip. J. Geophys. Res. B 84, 2169–2175 (1979)

Rice, J.R., Ruina, A.: Stability of steady frictional sliding. J. Appl. Mech. 50, 343–349 (1983)

Irfan, M.A., Prakash, V.: Time resolved friction during dry sliding of metal on metal. Int. J. Solids. Struc. 37, 2859–2882 (2000)

Acknowledgments

The materials reported in this article are from the work supported by the U. S. Army Research Office through Grant No. DAAD19-99-1-0117. Technical support from the Machine Shop in the College of Engineering and Technology, University of Nebraska-Lincoln is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Huang, H., Feng, R. Dynamic Friction of SiC Surfaces: A Torsional Kolsky Bar Tribometer Study. Tribol Lett 27, 329–338 (2007). https://doi.org/10.1007/s11249-007-9239-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-007-9239-4