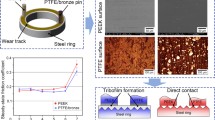

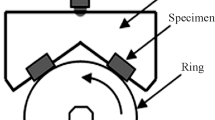

An energetic approach to model the wear of tribological systems in which one of the components of the pair is polymeric is presented in this work. Experimental data, obtained in ultra-high molecular weight polyethylene (UHMWPE) pin-on-disk tribological tests, showed that a linear correlation between the wear rate of the polymer and the dissipated energy exists, independently of the lubricant, of the material used as counterbody and of the surface finishing of both polymer and counterbody. This fact strongly suggests that, in UHMWPE-based tribological systems, energy dissipation is mainly caused by the elasto-plastic deformation and wear of the polymer. Based on this assumption, it is developed a mathematical model that yields for a physical interpretation of the parameters of the experimental wear vs. energy correlation. These parameters are intrinsic wear properties of the polymer and can be used for the optimization of polymer-based tribological systems.

Similar content being viewed by others

References

Huq M.Z., Celis (2002) Wear 252:375

Fouvry S., Liskiewicz T., Kapsa P., Hannel S., Sauger E. (2003) Wear 255:287

Fouvry S., Liskiewicz T. (2005) Trib. Int. 38:69

Ramalho A., Miranda J.C. (2006) Wear 260:361

S.K. Sinha in ASM International Handbook. (ASM International, Ohio, 2002, 1019)

Satyanarayana N., Sinha S.K., Ong B.H. (2006) Sens. Actuators - A 128:98

McKellop H., Clarke I.C., Markolf K.L., Amstutz H.C. (1978) J. Biomed Mater. Res. 12(6):895

Wright T.M., Fukubayashi T., Burstein A.H. (1991) J. Biomed. Mater. Res. 15:719

S. Li and E.G. Howard US Patent 5-037-928-1991, USA (1991)

Muratoglu O.K., Bragdon C.R., O’Connor D.O., Jasty M., Harris W.H. (2001) J. Arthopl. 16(2):149

Pichat A., Rabbe L.M., Rieu J., Rambert A., Chabrol C., Robelet M. (1991) Surf. Coat. Tech. 45(1–3):15

Alonso F., Ugarte J.J., Sansom D., Viviente J.L., Oñate J.I. (1996) Surf and Coat Tech 83:301

Torrisi L., Visco A.M., Valenza A. (2003) Radiation Effects and Defects in Solids 158(9):621

Gutmanas E.Y., Gotman I. (2004) J. Mater. Sci. – Mat. Med. 15(4):327

Xiong D.S., Jin Z.M. (2004) Surf. Coat. Tech. 182(2–3):149

M.P. Gispert, A.P. Serro, R. Colaço, A. Rego, E. Alves, R.C. Silva, P. Brogueira, E. Pires and B. Saramago, Wear (in press)

Sawae Y., Murakami T., Chen J. (1998) Wear 216:213

Saikko V. (2003) Trans. ASME 125:638

Gispert M.P., Serro A.P., Colaço R., Saramago B. (2006) Wear 260:149

Serro A.P., Gispert M.P., Martins M.C.L., Brogueira P., Colaço R., Saramago B. (2006) J. Biomed. Mat. Res.: Part A 78A(3):581

Wang A., Polieni V.K., Stark C., Dumbleton J.H. (1998) J. Arthoplasty 13(6):615

Saikko V., Calonius O., Keranen J. (2001) J. Biomed. Mat. Res. 57(4):506–512

M.P. Gispert, A.P. Serro, R. Colaço, and B. Saramago, J. Biomed. Mater. Res.: Part B (submitted)

Morbacher H., Blanpain B., Celis J.-P., Roos J.R. (1995) Wear 180:43

Archard J.F. (1953) J. Appl. Phys. 24(8):981

E. Rabinowicz, Friction and Wear of Materials (John Wiley and Sons, 1965)

Acknowledgments

This study was financially supported by the programme POCI 2010 under project POCI/SAU-BMA/55493/2004. M. Gispert and A.P. Serro acknowledge the Portuguese Foundation for Science for the research grant financed by the project and for the post-doctoral grant SFRH/BPD/5666/2001, respectively. The authors also acknowledge Dr. E. Alves and Dr. R. C. Silva from ITN and Dr. E. Pires, from CERAMED, for preparing the Cl and Ar implanted and the TiN samples, respectively, and to Poly Hi Solidur who kindly offered the UHMWPE.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Colaço, R., Gispert, M., Serro, A. et al. An energy-based model for the wear of UHMWPE. Tribol Lett 26, 119–124 (2007). https://doi.org/10.1007/s11249-006-9159-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-006-9159-8