Abstract

In this study, a series of nickels supported on gamma alumina with a metal dosage ranging from 0.5 to 3 wt.% were prepared and employed as the catalysts. The effect of nickel dosage on material properties, reaction performance, and catalyst deactivation was investigated. At a low dosage, the nickel-free having low metal-support interaction contributed significantly to the total active site. The basicity of the material was enhanced along with the increase in nickel loading. The presence of active metal showed a great impact at the beginning leading to big improvements in feedstock conversion. However, beyond a nickel dosage of 2 wt.%, further additions did not noticeably influence the reaction performance. Regarding catalyst deactivation, different carbon species were observed on catalyst surface, depending on the nickel dosage. Catalysts with less than 2 wt.% nickel exhibited amorphous carbon as the dominant morphology on the spent catalyst. In contrast, catalysts with 2Ni/Al2O3 and 3Ni/Al2O3 compositions showed graphitic carbon as the main side product. These findings provide insights into the relationship between nickel dosage, catalyst properties, and catalytic performance in methane dry reforming. By understanding the effects of nickel loading on material properties and reaction behavior, researchers can optimize catalyst design and develop more efficient and stable catalysts for sustainable syngas production.

Similar content being viewed by others

References

Horiuchi T (1996) Suppression of carbon deposition in the CO2-reforming of CH4 by adding basic metal oxides to a Ni/Al2O3 catalyst. Appl Catal A Gen 144: 111–120

Xu L, Song H, Chou L (2013) Ordered mesoporous MgO–Al2O3 composite oxides supported Ni based catalysts for CO2 reforming of CH4: effects of basic modifier and mesopore structure. Int J Hydrog Energy

Muraza O, Galadima A (2015) A review on coke management during dry reforming of methane. Int J Energy Res 39(9):1196–1216

Wang C et al (2021) Recent advances during CH4 dry reforming for syngas production: a mini review. Int J Hydrog Energy 46(7):5852–5874

Pakhare D, Spivey J (2014) A review of dry (CO2) reforming of methane over noble metal catalysts. Chem Soc Rev 43(22):7813–7837

Parsapur RK, Chatterjee S, Huang K-W (2020) The insignificant role of dry reforming of methane in CO2 Emission Relief. ACS Energy Letters 5(9):2881–2885

Hassan-Legault K, Mohan O, Mushrif SH (2019) Molecular insights into the activity and stability of popular methane reforming catalysts using quantum mechanical tools. Curr Opin Chem Eng 26:38–45

Bai Y et al (2019) Atomic and molecular adsorption on Ni(111). Surf Sci 679:240–253

Kawi S et al (2015) Progress in synthesis of highly active and stable nickel-based catalysts for Carbon Dioxide Reforming of methane. Chemsuschem 8(21):3556–3575

Cao T (2023) Insight into the role of material basicity in the coke formation and performance of Ni/Al2O3 catalyst for the simulated- biogas dry reforming. J Energy Inst 108:101252

Al-Swai BM et al (2019) Syngas Production via Methane Dry reforming over Ceria–magnesia mixed oxide-supported nickel catalysts. Ind Eng Chem Res 58(2):539–552

Kim SM et al (2017) Cooperativity and dynamics increase the performance of NiFe Dry reforming catalysts. J Am Chem Soc 139(5):1937–1949

Theofanidis SA et al (2015) Enhanced Carbon-Resistant Dry Reforming Fe-Ni Catalyst: Role of Fe. ACS Catal 5(5):3028–3039

de Miguel SR et al (2012) Influence of pt addition to Ni catalysts on the catalytic performance for long term dry reforming of methane. Appl Catal A 435–436: 10–18

Siang TJ et al (2018) Hydrogen production from CH4 dry reforming over bimetallic Ni–Co/Al2O3 catalyst. J Energy Inst 91(5):683–694

Juan-Juan J, Román-Martínez MC, Illán-Gómez MJ (2006) Effect of potassium content in the activity of K-promoted Ni/Al2O3 catalysts for the dry reforming of methane. Appl Catal A 301(1):9–15

Juan-Juan J, Román-Martínez MC, Illán-Gómez MJ (2004) Catalytic activity and characterization of Ni/Al2O3 and NiK/Al2O3 catalysts for CO2 methane reforming. Appl Catal A 264(2):169–174

Damyanova S et al (2020) Characterization of none and yttrium-modified Ni-based catalysts for dry reforming of methane. Appl Catal B 278:119335

Fakeeha AH et al (2018) Iridium promoted Ni-Co/Al2O3-ZrO2 catalyst for dry reforming of methane. Can J Chem Eng 96(4):955–960

Hambali HU et al (2020) Effect of Ni-Ta ratio on the catalytic selectivity of fibrous Ni-Ta/ZSM-5 for dry reforming of methane. Chem Eng Sci 227:115952

Jin B, Li S, Liang X (2021) Enhanced activity and stability of MgO-promoted Ni/Al2O3 catalyst for dry reforming of methane: role of MgO. Fuel 284:119082

Cao ANT et al (2022) Dysprosium promotion on Co/Al2O3 catalysts towards enhanced hydrogen generation from methane dry reforming. Fuel 324:124818

Pham CQ et al (2022) Influence of synthesis routes on the performance of Ni nano-sized catalyst supported on CeO2-Al2O3 in the dry reforming of methane. Adv Nat Sci NanoSci NanoTechnol 13(3):035011

Pham CQ et al (2022) Syngas Production from Biogas Reforming: role of the support in Nickel-based Catalyst Performance. Top Catal

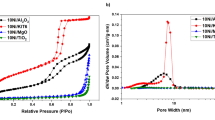

Sing KSW (1985) Reporting physisorption data for gas/solid systems with special reference to the determination of surface area and porosity (recommendations 1984). Pure Appl Chem 57(4):603–619

Leofanti G et al (1998) Surface area and pore texture of catalysts. Catal Today 41(1):207–219

Liang Z et al (2023) Promotion effect of different lanthanide doping on Co/Al2O3 catalyst for dry reforming of methane. Int J Hydrog Energy 48(49):18644–18656

Cao ANT et al (2021) Boosted methane dry reforming for hydrogen generation on cobalt catalyst with small cerium dosage. Int J Hydrog Energy

Feng Y et al (2016) Novel three-dimensional flower-like porous Al2O3 nanosheets anchoring hollow NiO nanoparticles for high-efficiency lithium ion batteries. J Mater Chem A 4(29):11507–11515

Penkova A et al (2011) Hydrogen production by methanol steam reforming on NiSn/MgO–Al2O3 catalysts: the role of MgO addition. Appl Catal A 392(1):184–191

Huang F et al (2016) Catalytic performances of Ni/mesoporous SiO2 catalysts for dry reforming of methane to hydrogen. J Energy Chem 25(4):709–719

Patterson AL (1939) The Scherrer Formula for X-Ray particle size determination. Phys Rev 56(10):978–982

Pizzolato M et al (2023) Vanadium doped Ni/Al2O3: efficient and coke resistant catalysts for methane dry reforming. Catal Today 418:114041

Soloviev SO et al (2011) Carbon dioxide reforming of methane on monolithic Ni/Al2O3-based catalysts. J Nat Gas Chem 20(2):184–190

Al-Fatesh AS et al (2013) CO2 reforming of methane to produce syngas over γ-Al2O3-Supported Ni–Sr catalysts. Bull Chem Soc Jpn 86(6): 742–748

Ni J et al (2012) Carbon deposition on borated alumina supported nano-sized ni catalysts for dry reforming of CH4. Nano Energy 1(5):674–686

Parkyns ND (1969) The surface properties of metal oxides. Part II. An infrared study of the adsorption of carbon dioxide on γ-alumina. J Chem Soc A: Inorg Phys Theoretical (0): 410–417

Wang X et al (2011) Surface basicity on bulk modified phosphorus alumina through different synthesis methods. Phys Chem Chem Phys 13(34):15589–15596

Montanari T et al (2011) Basic catalysis and catalysis assisted by basicity: FT-IR and TPD characterization of potassium-doped alumina. Appl Catal A 400(1):61–69

Vo C-M et al (2022) Toward syngas production from simulated biogas dry reforming: Promotional effect of calcium on cobalt-based catalysts performance. Fuel 326:125106

Al-Fatesh AS et al (2015) The effect of sc promoter on the performance of Co/TiO2–P25 Catalyst in Dry Reforming of methane. Bull Korean Chem Soc 36(8):2081–2088

Rodriguez-Gomez A et al (2021) Elucidating the Promotional Effect of Cerium in the dry reforming of methane. ChemCatChem 13(2):553–563

Ha NN et al (2015) Theoretical study of carbon dioxide activation by metals (Co, Cu, Ni) supported on activated carbon. J Mol Model 21(12):322

Pham CQ et al (2022) Enhancement of syngas production from dry reforming of methane over Co/Al2O3 catalyst: insight into the promotional effects of europium and neodymium. J Energy Inst 105:314–322

Lee MB et al (1986) Activated dissociative chemisorption of CH4 on Ni(111): Observation of a methyl radical and implication for the pressure gap in catalysis. J Chem Phys 85(3):1693–1694

Lee MB, Yang QY, Ceyer ST (1987) Dynamics of the activated dissociative chemisorption of CH4 and implication for the pressure gap in catalysis: a molecular beam–high resolution electron energy loss study. J Chem Phys 87(5):2724–2741

Roy G, Chattopadhyay AP (2017) Dissociation of methane on Ni4 cluster-A DFT study. Comput Theor Chem 1106:7–14

Hambali HU et al (2020) Fibrous spherical Ni-M/ZSM-5 (M: mg, ca, Ta, Ga) catalysts for methane dry reforming: the interplay between surface acidity-basicity and coking resistance. Int J Energy Res 44(7):5696–5712

Wang HY, Ruckenstein E (2001) CO2 reforming of CH4 over Co/MgO solid solution catalysts — effect of calcination temperature and Co loading. Appl Catal A 209(1):207–215

Dama S et al (2018) Active and durable alkaline earth metal substituted perovskite catalysts for dry reforming of methane. Appl Catal B 224:146–158

Arora S, Prasad R (2016) An overview on dry reforming of methane: strategies to reduce carbonaceous deactivation of catalysts. RSC Adv 6(110):108668–108688

Jiang Z, Liao X, Zhao Y (2013) Comparative study of the dry reforming of methane on fluidised aerogel and xerogel Ni/Al2O3 catalysts. Appl Petrochemical Res 3(3):91–99

Acknowledgements

Authors are thankful to the Deanship of Scientific Research at Najran University for funding this work under the Research Group Funding program grant code (NU/RG/SERC/12/1). This research is funded by Nguyen Tat Thanh University, Ho Chi Minh City, Vietnam.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic Supplementary Material

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Pham, C.Q., Alsaiari, M., Hieu, N.H. et al. Efficient Methane Dry Reforming Process with Low Nickel Loading for Greenhouse Gas Mitigation. Top Catal 67, 748–760 (2024). https://doi.org/10.1007/s11244-023-01881-w

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11244-023-01881-w