Abstract

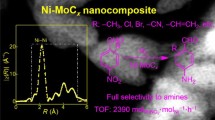

Self-organizing catalytic systems are promising for synthesis of carbon nanomaterials via catalytic chemical vapor deposition. The precursors of catalysts, 100Ni and 96Ni–4Mo, were synthesized by reductive thermolysis at 800 °C and tested in the H2-assisted catalytic pyrolysis of C2HCl3 to produce carbon nanofibers. The reaction temperature was varied in a range of 475–675 °C. The kinetics of carbon accumulation over the prepared catalysts was studied to reveal the effect of Mo on the catalytic performance of nickel. It was shown that the process is characterized by the presence of induction period, and the addition of molybdenum to nickel leads to a shortening of this period in ~ 70% along with an increase in the C2HCl3 decomposition rate and boosting the carbon yield. The maximum yield of the carbon nanomaterial obtained after 2 h of the C2HCl3 decomposition over 96Ni–4Mo alloy at 600 °C was as high as 89 g/gcat. The presence of Mo in the catalyst’s composition also leads to a decrease in activation energy value from 79 to 55 kJ/mol. The longevity tests performed at 600 °C for 7 h showed that the bimetallic 96Ni–4Mo alloy provides productivity of 259 g/gcat, which is 2.2 times higher than for the monometallic 100Ni catalyst. According to transmission and scanning electron microscopies, the obtained carbon nanomaterial is predominantly represented by long filaments attached to submicron-sized catalytic particles. The carbon nanofibers are characterized by a defective and non-uniform segmented secondary structure and possess high specific surface area (up to 385 m2/g).

Similar content being viewed by others

References

Jin Y, Ren J, Chen J, Dai Z, Li B, Zhou X (2018) Controllable preparation of helical carbon nanofibers by CCVD method and their characterization. Mater Res Express 5(1):015601. https://doi.org/10.1088/2053-1591%2FAAA09C

Zhang Y, Liu F, Zhang ZH (2011) Synthesis of heterostructured helical carbon nanotubes by iron-catalyzed ethanol decomposition. Micron 42:547–552. https://doi.org/10.1016/j.micron.2011.01.007

Lu M, Liu W, Guo X, Li H (2004) Coiled carbon nanotubes growth via reduced-pressure catalytic chemical vapor deposition. Carbon 42:805–811. https://doi.org/10.1016/j.carbon.2004.01.051

Li M, Carter R, Cohn AP, Pint CL (2016) Interconnected foams of helical carbon nanofibers grown with ultrahigh yield for high capacity sodium ion battery anodes. Carbon 107:109–115. https://doi.org/10.1016/j.carbon.2016.05.051

Huang Z, Zhang J, Du Y, Zhang Y, Wu X, Jing G (2020) Self-assembly of atomically dispersed Ag catalysts on polyhedral Co3O4 at elevated temperatures: a top-down nanofabrication of high-loading atomically dispersed catalysts. ChemCatChem 12(2):561–568. https://doi.org/10.1002/cctc.201901712

Satsuma A, Yanagihara M, Ohyama J, Shimizu K (2013) Oxidation of CO over Ru/Ceria prepared by self-dispersion of Ru metal powder into nano-sized particle. Catal Today 201:62–67. https://doi.org/10.1016/j.cattod.2012.03.048

Li H, Wan Q, Du C, Liu Q, Qi J, Ding X, Wang S, Wan S, Lin J, Tian C, Li L, Peng T, Zhao W, Zhang K, Huang J, Zhang X, Gu Q, Yang B, Guo H, Lin S, Datye A, Wang Y, Xiong H (2022) Vapor-phase self-assembly for generating thermally stable single-atom catalysts. Chem 8(3):731–748. https://doi.org/10.1016/j.chempr.2021.11.002

Grabke HJ, Schütze M (2007) Metal dusting, carburisation and nitridation. In: Grabke HJ, Schütze M (eds) Corrosion by carbon and nitrogen. Woodhead Publ, Sawston

Chang JK, Tsai HY, Tsai WT (2008) A metal dusting process for preparing nano-sized carbon materials and the effects of acid post-treatment on their hydrogen storage performance. Int J Hydrog Energy 33:6734–6742. https://doi.org/10.1016/j.ijhydene.2008.08.018

Maubane MS, Bhoware SS, Shaikjee A, Coville NJ (2017) From carbon dots to multipods—the role of nickel particle shape and size. Diam Relat Mater 72:53–60. https://doi.org/10.1016/j.diamond.2016.12.023

Romero P, Oro R, Campos M, Torralba JM, de Villoria RG (2015) Simultaneous synthesis of vertically aligned carbon nanotubes and amorphous carbon thin films on stainless steel. Carbon 82:31–38. https://doi.org/10.1016/j.carbon.2014.10.020

Sridhar D, Omanovic S, Meunier JL (2018) Direct growth of carbon nanofiber forest on nickel foam without any external catalyst. Diam Relat Mater 81:70–76. https://doi.org/10.1016/j.diamond.2017.11.011

Yin X, He L, Syed-Hassan SSA, Deng W, Ling P, Xiong Y, Hu X, Su S, Hu S, Wang XJ (2020) One-step preparation of a N-CNTs@Ni foam electrode material with the co-production of H2 by catalytic reforming of N-containing compound of biomass tar. Fuel 280:118601. https://doi.org/10.1016/j.fuel.2020.118601

Lin WH, Lee TT, Li YY (2014) Chlorine effect on formation of turbostratic carbon nanofibers by a mixture of 1,2-dichloroethane and ethanol. J Taiwan Inst Chem Eng 45:1883–1891. https://doi.org/10.1016/j.jtice.2013.10.015

Buyanov RA, Chesnokov VV (2006) On mechanism of formation of carbon nanofilaments during catalytic decomposition of hydrocarbons over iron-subgroup metals. Catal Ind 2:3–15

Netskina OV, Tayban ES, Moiseenko AP, Komova OV, Mukha SA, Simagina VI (2015) Removal of 1,2-dichlorobenzene from water emulsion using adsorbent-catalysts and its regeneration. J Hazard Mater 285:84–93. https://doi.org/10.1016/j.jhazmat.2014.10.017

Gusain R, Kumar N, Ray SS (2020) Recent advances in carbon nanomaterial-based adsorbents for water purification. Coord Chem Rev 405:213111. https://doi.org/10.1016/j.ccr.2019.213111

Santiago-Calvo M, Tirado-Mediavilla J, Rauhe JC, Jensen LR, Ruiz-Herrero JL, Villafane F, Rodriguez-Perez MA (2018) Evaluation of the thermal conductivity and mechanical properties of water blown polyurethane rigid foams reinforced with carbon nanofibers. Eur Polym J 108:98–106. https://doi.org/10.1016/j.eurpolymj.2018.08.051

Al-Saleh MH, Sundararaj U (2009) A review of vapor grown carbon nanofiber/polymer conductive composites. Carbon 47:2–22. https://doi.org/10.1016/j.carbon.2008.09.039

Chowdhury SA, Saha MC, Patterson S, Robison T, Liu Y (2019) Highly conductive polydimethylsiloxane/carbon nanofiber composites for flexible sensor applications. Adv Mater Technol 4:1800398. https://doi.org/10.1002/admt.201800398

Peng S, Li L, Lee JKY, Tian L, Srinivasan M, Adams S, Ramakrishna S (2016) Electrospun carbon nanofibers and their hybrid composites as advanced materials for energy conversion and storage. Nano Energy 22:361–395. https://doi.org/10.1016/j.nanoen.2016.02.001

Ochoa-Fernandez E, Chen D, Yu Z, Totdal B, Ronning M, Holmen A (2005) Carbon nanofiber supported Ni catalyst: effects of nanostructure of supports and catalyst preparation. Catal Today 102–103:45–49. https://doi.org/10.1016/j.cattod.2005.02.005

Ruiz-Cornejo JC, Vivo-Vilches JF, Sebastian D, Martinez-Huerta MV, Lazaro MJ (2021) Carbon nanofiber-supported tantalum oxides as durable catalyst for the oxygen evolution reaction in alkaline media. Renew Energy 178:307–317. https://doi.org/10.1016/j.renene.2021.06.076

Rosner D, Markowitz G (2013) Persistent pollutants: a brief history of the discovery of the widespread toxicity of chlorinated hydrocarbons. Environ Res 120:126–133. https://doi.org/10.1016/j.envres.2012.08.011

Malik JK, Aggarwal M, Kalpana S, Gupta RC (2022) Chlorinated hydrocarbons and pyrethrins/pyrethroids. In: Gupta RC (ed) Reproductive and developmental toxicology, 3rd edn. Academic Press, Cambridge

Adeola AO (2018) Fate and toxicity of chlorinated phenols of environmental implications: a review. Med Anal Chem Int J 2:000126. https://doi.org/10.23880/macij-16000126

Mishakov IV, Chesnokov VV, Buyanov RA, Pakhomov NA (2001) Decomposition of chlorinated hydrocarbons on iron-group metals. Kinet Catal 42:543–548. https://doi.org/10.1023/A:1010585808978

Shaikjee A, Coville NJ (2012) The effect of substituted alkynes on nickel catalyst morphology and carbon fiber growth. Carbon 50(3):1099–1108. https://doi.org/10.1016/j.carbon.2011.10.020

Nieto-Marquez A, Valverde JL, Keane MA (2007) Catalytic growth of structured carbon from chloro-hydrocarbons. Appl Catal A Gen 332:237–246. https://doi.org/10.1016/j.apcata.2007.08.028

Bauman YI, Mishakov IV, Vedyagin AA, Dmitriev SV, Melʹgunov MS, Buyanov RA (2012) Processing of organochlorine waste components on bulk metal catalysts. Catal Ind 4(4):261–266. https://doi.org/10.1134/S2070050412040034

Bauman YI, Mishakov IV, Korneev DV, Shubin YV, Vedyagin AA, Buyanov RA (2018) Comparative study of 1,2-dichlorethane decomposition over Ni-based catalysts with formation of filamentous carbon. Catal Today 301:147–152. https://doi.org/10.1016/j.cattod.2017.05.015

Wang C, Bauman YI, Mishakov IV, Stoyanovskii VO, Shelepova EV, Vedyagin AA (2022) Scaling up the process of catalytic decomposition of chlorinated hydrocarbons with the formation of carbon nanostructures. Processes 10:506. https://doi.org/10.3390/pr10030506

Mishakov IV, Bauman YI, Potylitsyna AR, Shubin YV, Plyusnin PE, Stoyanovskii VO, Vedyagin AA (2022) Catalytic properties of bulk (1–x)Ni–xW alloys in the decomposition of 1,2-dichloroethane with the production of carbon nanomaterials. Kinet Catal 63:75–86. https://doi.org/10.1134/S0023158422010037

Bauman YI, Shorstkaya YV, Mishakov IV, Plyusnin PE, Shubin YV, Korneev DV, Stoyanovskii VO, Vedyagin AA (2017) Catalytic conversion of 1,2-dichloroethane over Ni-Pd system into filamentous carbon material. Catal Today 293–294:23–32. https://doi.org/10.1016/j.cattod.2016.11.020

Bauman YI, Rudneva YV, Mishakov IV, Plyusnin PE, Shubin YV, Korneev DV, Buyanov RA (2019) Effect of Mo on the catalytic activity of Ni-based self-organizing catalysts for processing of dichloroethane into segmented carbon nanomaterials. Heliyon 5:e02428. https://doi.org/10.1016/j.heliyon.2019.e02428

Lobiak EV, Shlyakhova EV, Bulusheva LG, Plyusnin PE, Shubin YV, Okotrub AV (2015) Ni–Mo and Co–Mo alloy nanoparticles for catalytic chemical vapor deposition synthesis of carbon nanotubes. J Alloy Comp 621:351–356. https://doi.org/10.1016/j.jallcom.2014.09.220

Shaikjee A, Coville NJ (2012) Catalyst restructuring studies: the facile synthesis of tripod-like carbon fibers by the decomposition of trichloroethylene. Mater Lett 68:273–276. https://doi.org/10.1016/j.matlet.2011.10.083

Mishakov IV, Vedyagin AA, Bauman YI, Shubin YV, Buyanov RA (2018) In carbon nanofibers: synthesis, applications and performance (ed) Synthesis of carbon nanofibers via catalytic chemical vapor deposition of halogenated hydrocarbons. New York

Klyuchnikov NG (1988) Neorganicheskii sintez. Prosveshchenie, Moscow

Powder Diffraction File (2009) PDF-2/Release, International Centre for Diffraction Data, USA

Rudnev AV, Lysakova AS, Plyusnin PE, Bauman YI, Shubin YV, Mishakov IV, Vedyagin AA, Buyanov RA (2014) Ni–Cu and Ni–Co alloys: synthesis, structure, and catalytic activity for the decomposition of chlorinated hydrocarbons. Inorg Mater 50(6):566–571. https://doi.org/10.1134/S0020168514060156

Rudneva YV, Shubin YV, Plyusnin PE, Bauman YI, Mishakov IV, Korenev SV, Vedyagin AA (2019) Preparation of highly dispersed Ni1-xPdx alloys for the decomposition of chlorinated hydrocarbons. J Alloys Compd 782:716–722. https://doi.org/10.1016/j.jallcom.2018.12.207

Shubin YV, Bauman YI, Plyusnin PE, Mishakov IV, Tarasenko MS, Mel’gunov MS, Stoyanovskii VO, Vedyagin AA (2021) Facile synthesis of triple Ni-Mo-W alloys and their catalytic properties in chemical vapor deposition of chlorinated hydrocarbons. J Alloys Compd 866:158778. https://doi.org/10.1016/j.jallcom.2021.158778

Bauman YI, Mishakov IV, Buyanov RA, Vedyagin AA, Volodin AM (2011) Catalytic properties of massive iron-subgroup metals in dichloroethane decomposition into carbon products. Kinet Catal 52:547–554. https://doi.org/10.1134/S002315841104001X

Bauman YI, Lysakova AS, Rudnev AV, Mishakov IV, Shubin YV, Vedyagin AA, Buyanov RA (2014) Synthesis of nanostructured carbon fibers from chlorohydrocarbons over bulk Ni–Cr alloys. Nanotechnol Russ 9:380–385. https://doi.org/10.1134/S1995078014040041

Bauman YI, Netskina OV, Mukha SA, Mishakov IV, Shubin YV, Stoyanovskii VO, Nalivaiko AY, Vedyagin AA, Gromov AA (2020) Adsorption of 1, 2-dichlorobenzene on a carbon nanomaterial prepared by decomposition of 1, 2-dichloroethane on nickel alloys. Russ J Appl Chem 93:1873–1882. https://doi.org/10.1134/S1070427220120095

Palmeri MJ, Putz KW, Ramanathan T, Brinson LC (2011) Multi-scale reinforcement of CFRPs using carbon nanofibers. Compos Sci Technol 71:79–86. https://doi.org/10.1016/j.compscitech.2010.10.006

Zhou Y, Jeelani S, Lacy T (2014) Experimental study on the mechanical behavior of carbon/epoxy composites with a carbon nanofiber-modified matrix. J Compos Mater 48:3659–3672. https://doi.org/10.1177/0021998313512348

Acknowledgements

Analysis of the physicochemical properties of the samples was performed using the equipment of the “National Center for Catalyst Research”. The authors are grateful to AN Serkova and MN Volochaev for their help in the electron microscopy studies, and to AB Ayupov for the low-temperature nitrogen adsorption/desorption analysis.

Funding

This work was financially supported by the Ministry of Science and Higher Education of the Russian Federation (project Grant No. AAAA-A21-121011390054-1). The synthesis and X-ray diffraction analysis of the starting materials were supported by the Russian Science Foundation (project Grant No. 21-13-00414).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Potylitsyna, A.R., Bauman, Y.I., Mishakov, I.V. et al. The Features of the CCVD of Trichloroethylene Over Microdispersed Ni and Ni–Mo Catalysts. Top Catal 66, 326–337 (2023). https://doi.org/10.1007/s11244-022-01698-z

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11244-022-01698-z