Abstract

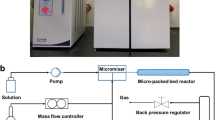

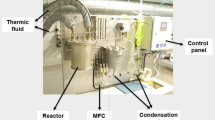

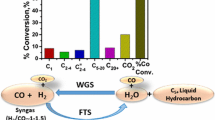

In this work, Pt based mono and bimetallic catalysts were tested under conditions of tri-reforming (TR). All the catalysts contained 25% of CeO2 and a metal loading of 2.5 or 5.0% (wt%). The bimetallic catalysts contained 2.5% Pt and 2.5% of Me, where Me = Ni, Co, Mo, Pd, Fe, Re, Y, Cu or Zn. For all the experiments, a synthetic biogas which consisted of 60% CH4 and 40% CO2 (vol.) was mixed with water, S/C = 1.0, and oxygen, O2/CH4 = 0.25, and fed to a fixed bed reactor (FBR) system or a microreactor. The 2.5Pt catalyst was used in order to compare the performance of each reaction system. The tests were performed at reaction temperatures between 700 and 800 °C, and at volume hourly space velocities (VHSV) between 100 LN/(h gcat) and 200 LN/(h gcat) for the FBR system and between 1000 LN/(h gcat) and 2000 LN/(h gcat) for the microreactor, at atmospheric pressure. Then, all catalysts were deposited into microchannel reactors and tested at a constant VHSV of 2000 LN/(h gcat) and reaction temperatures between 700 and 800 °C. Catalysts under investigation were characterized applying the following techniques: inductively coupled plasma optical emission spectroscopy (ICP-OES), N2 Physisorption, Temperature Programmed Reduction (TPR), CO chemisorption, Transmission Electron Microscopy (TEM) and X-ray Photoelectron Spectroscopy (XPS). The microreactor was identified as the most efficient and promising reaction system, and the 2.5(Pt–Pd) catalyst as the bimetallic formulation with the highest activity. Therefore its activity and stability was compared with the reference 5.0Pt catalyst at 700 °C and VHSV of 2000 LN/(h gcat) for more than 100 h. Although slightly lower activity was measured operating with the 2.5(Pt–Pd) catalyst, a significant reduction of the Pt content compared to the reference 5.0Pt catalyst was achieved through the incorporation of Pd.

Similar content being viewed by others

References

Rasi S, Veijanen A, Rintala J (2007) Trace compounds of biogas from different biogas production plants. Energy 32:1375–1380. doi:10.1016/j.energy.2006.10.018

Alves HJ, Bley Junior C, Niklevicz RR et al (2013) Overview of hydrogen production technologies from biogas and the applications in fuel cells. Int J Hydrogen Energy 38:5215–5225. doi:10.1016/j.ijhydene.2013.02.057

Kolb G, Hessel V (2004) Micro-structured reactors for gas phase reactions. Chem Eng J 98:1–38. doi:10.1016/j.cej.2003.10.005

Kolb G, Baier T, Schürer J et al (2008) A micro-structured 5 kW complete fuel processor for iso-octane as hydrogen supply system for mobile auxiliary power units. Part II-development of water-gas shift and preferential oxidation catalysts reactors and assembly of the fuel processor. Chem Eng J 138:474–489. doi:10.1016/j.cej.2007.06.037

Germani G, Alphonse P, Courty M et al (2005) Platinum/ceria/alumina catalysts on microstructures for carbon monoxide conversion. Catal Today 110:114–120. doi:10.1016/j.cattod.2005.09.017.

Prieto PJS, Ferreira AP, Haddad PS et al (2010) Designing Pt nanoparticles supported on CeO2–Al2O3: synthesis, characterization and catalytic properties in the steam reforming and partial oxidation of methane. J Catal 276:351–359. doi:10.1016/j.jcat.2010.09.025

Duarte RB, Damyanova S, de Oliveira DC et al (2011) Study of Sm2O3-doped CeO2–Al2O3-supported Pt catalysts for partial CH4 oxidation. Appl Catal A Gen 399:134–145. doi:10.1016/j.apcata.2011.03.045

Ferreira AP, Zanchet D, Rinaldi R et al (2010) Effect of the CeO2 content on the surface and structural properties of CeO2-Al2O3 mixed oxides prepared by sol–gel method. Appl Catal A Gen 388:45–56. doi:10.1016/j.apcata.2010.08.033

Niu J, Du X, Ran J, Wang R (2016) Dry (CO2) reforming of methane over Pt catalysts studied by DFT and kinetic modeling. Appl Surf Sci 376:79–90. doi:10.1016/j.apsusc.2016.01.212

Elsayed NH, Roberts NRM, Joseph B, Kuhn JN (2015) Low temperature dry reforming of methane over Pt–Ni–Mg/ceria-zirconia catalysts. Appl Catal B Environ 179:213–219. doi:10.1016/j.apcatb.2015.05.021

Hassani Rad SJ, Haghighi M, Alizadeh Eslami A et al (2016) Sol–gel versus impregnation preparation of MgO and CeO2 doped Ni/Al2O3 nanocatalysts used in dry reforming of methane: effect of process conditions, synthesis method and support composition. Int J Hydrog Energy 41:5335–5350. doi:10.1016/j.ijhydene.2016.02.002

Luisetto I, Tuti S, Battocchio C et al (2015) Ni/CeO2–Al2O3 catalysts for the dry reforming of methane: the effect of CeAlO3 content and nickel crystallite size on catalytic activity and coke resistance. Appl Catal A Gen 500:12–22. doi:10.1016/j.apcata.2015.05.004

Levalley TL, Richard AR, Fan M (2014) The progress in water gas shift and steam reforming hydrogen production technologies—a review. Int J Hydrog Energy 39:16983–17000. doi:10.1016/j.ijhydene.2014.08.041

Cheekatamarla PK, Finnerty CM (2006) Reforming catalysts for hydrogen generation in fuel cell applications. J Power Sour 160:490–499. doi:10.1016/j.jpowsour.2006.04.078

Jiao Y, Sun D, Zhang J et al (2016) Steam reforming of n-decane toward H2 production over Ni/Ce–Al2O3 composite catalysts: effects of M (M = Fe, Co, Cu, Zn) promoters. J Anal Appl Pyrolysis 120:238–246. doi:10.1016/j.jaap.2016.05.011

Jiao Y, Zhang J, Du Y et al (2016) Steam reforming of hydrocarbon fuels over M (Fe, Co, Ni, Cu, Zn)-Ce bimetal catalysts supported on Al2O3. Int J Hydrog Energy 41:10473–10482. doi:10.1016/j.ijhydene.2015.09.151

Turco M, Cammarano C, Bagnasco G et al (2009) Oxidative methanol steam reforming on a highly dispersed CuO/CeO2/Al2O3 catalyst prepared by a single-step method. Appl Catal B Environ 91:101–107. doi:10.1016/j.apcatb.2009.05.011

Malaibari ZO, Croiset E, Amin A, Epling W (2015) Effect of interactions between Ni and Mo on catalytic properties of a bimetallic Ni-Mo/Al2O3 propane reforming catalyst. Appl Catal A Gen 490:80–92. doi:10.1016/j.apcata.2014.11.002

Huang Z, Jiang H, He F et al (2016) Evaluation of multi-cycle performance of chemical looping dry reforming using CO2 as an oxidant with Fe–Ni bimetallic oxides. J Energy Chem 25:62–70. doi:10.1016/j.jechem.2015.10.008

Rosen BA, Gileadi E, Eliaz N (2016) Electrodeposited Re-promoted Ni foams as a catalyst for the dry reforming of methane. Catal Commun 76:23–28. doi:10.1016/j.catcom.2015.12.014

Carvalho LS, Conceição KCS, Mazzieri VA et al (2012) Pt–Re–Ge/Al2O3 catalysts for n-octane reforming: influence of the order of addition of the metal precursors. Appl Catal A Gen 419–420:156–163. doi:10.1016/j.apcata.2012.01.023

Ramírez-Hernández GY, Viveros-García T, Fuentes-Ramírez R, Galindo-Esquivel IR (2016) Promoting behavior of yttrium over nickel supported on alumina-yttria catalysts in the ethanol steam reforming reaction. Int J Hydrog Energy 41:9332–9343. doi:10.1016/j.ijhydene.2016.04.080

Lenarda M, Moretti E, Storaro L et al (2006) Finely dispersed Pd-Zn catalyst supported on an organized mesoporous alumina for hydrogen production by methanol steam reforming. Appl Catal A Gen 312:220–228. doi:10.1016/j.apcata.2006.07.004

Cassinelli, Damyanova, Parizotto et al (2014) Study of the properties of supported Pd catalysts for steam and autothermal reforming of methane. Appl Catal A Gen 475:256–269. doi:10.1016/j.apcata.2014.01.006

Roy PS, Park CS, Raju ASK, Kim K (2015) Steam-biogas reforming over a metal-foam-coated (Pd-Rh)/(CeZrO2–Al2O3) catalyst compared with pellet type alumina-supported Ru and Ni catalysts. J CO2 Util 12:12–20. doi:10.1016/j.jcou.2015.09.003

https://apps.catalysts.basf.com/apps/eibprices/mp/. Accessed 10 April 2017

Izquierdo U, Barrio VL, Requies J et al (2013) Tri-reforming: a new biogas process for synthesis gas and hydrogen production. Int J Hydrog Energy 38:7623–7631. doi:10.1016/j.ijhydene.2012.09.107

O’Connell M, Kolb G, Schelhaas KP et al (2012) Towards mass production of microstructured fuel processors for application in future distributed energy generation systems: a review of recent progress at IMM. Chem Eng Res Des 90:11–18. doi:10.1016/j.cherd.2011.08.002

O’Connell M, Kolb G, Zapf R, et al (2009) Bimetallic catalysts for the catalytic combustion of methane using microreactor technology. Catal Today 144:306–311. doi:10.1016/j.cattod.2008.10.053

Izquierdo U, Wichert M, Barrio VL, Kolb G (2014) Sustainable syngas production from ethylene glycol reforming processes using Rh-based catalysts in microreactors. Appl Catal B Environ 152–153:19–27. doi:10.1016/j.apcatb.2014.01.012

Izquierdo U, Barrio VL, Lago N et al (2012) Biogas steam and oxidative reforming processes for synthesis gas and hydrogen production in conventional and microreactor reaction systems. Int J Hydrog Energy 37:13829–13842. doi:10.1016/j.ijhydene.2012.04.077

Nevanperä TK, Ojala S, Bion N et al (2016) Catalytic oxidation of dimethyl disulfide (CH3SSCH3) over monometallic Au, Pt and Cu catalysts supported on γ-Al2O3, CeO2 and CeO2–Al2O3. Appl Catal B Environ 182:611–625. doi:10.1016/j.apcatb.2015.10.012

Chen Q-Y, Li N, Luo M-F, Lu J-Q (2012) Catalytic oxidation of dichloromethane over Pt/CeO2–Al2O3 catalysts. Appl Catal B Environ 127:159–166. doi:10.1016/j.apcatb.2012.08.020

Yang H, Deng J, Liu Y et al (2016) Preparation and catalytic performance of Ag, Au, Pd or Pt nanoparticles supported on 3DOM CeO2–Al2O3 for toluene oxidation. J Mol Catal A Chem 414:9–18. doi:10.1016/j.molcata.2015.12.010

Lieske H, Lietz G, Spindler JV H (1983) Reactions of platinum in oxygen- and hydrogen-treated Ptγ-Al2O3 catalysts: I. Temperature-programmed reduction, adsorption, and redispersion of platinum. J Catal 81:8–16. doi:10.1016/0021-9517(83)90142-2

P. Ciambelli, V. Palma, A. Ruggiero, et al, (2009) Platinum catalysts for the low temperature catalytic steam reforming of ethanol. AIDIC Conf Ser 09:83–92. doi:10.3303/ACOS0909011.

Ehrfeld W, Hessel V, Lowe H (2002) Microreactors: new technology for modern chemistry. Wiley-VCH, Weinheim

Jahnisch K, Hessel V, Lowe H, Baerns M (2004) Chemistry in microstructured reactors. Angew Chem Int Ed 43:406–446. doi:10.1002/anie.200300577

Acknowledgements

The authors would like to acknowledge the University of the Basque Country (UPV/EHU) for the postdoctoral scholarship and the Central Analysis Service (SGIker) of the UPV/EHU. This research was supported by the UPV/EHU, the Spanish Ministry of Economy and Competitiveness (MINECO, ENE2014-53566-P), edp company, the European Regional Development Fund (ERDF) and the Basque Country Government.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Izquierdo, U., García-García, I., Barrio, V.L. et al. Hydrogen Production with a Microchannel Reactor by Tri-Reforming; Reaction System Comparison and Catalyst Development. Top Catal 60, 1210–1225 (2017). https://doi.org/10.1007/s11244-017-0798-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11244-017-0798-9