Abstract

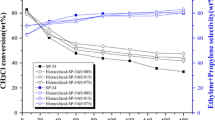

Six eight-membered-ring (8MR), microporous materials are synthesized and evaluated as catalysts for the methanol-to-olefins (MTO) reaction. The molecular sieves SSZ-13, SAPO-34, SAPO-39, MCM-35, ERS-7 and RUB-37 are investigated since they have 8MR access to the crystal interior but have differences in pore structure and cage size. The polymethylbenzene species that are the proposed reaction intermediates of the MTO reaction should only be able to form in materials with intra-molecular sieve void spaces of sufficient size to accommodate them. Thus, it is hypothesized that 8MR materials without adequately large pores or cages will be inactive for the MTO reaction. SSZ-13 and SAPO-34 (both with CHA framework topology) have interconnected 3-dimensional pore-and-cage systems sufficiently large for formation of the proposed reaction intermediates, while the other 8MR materials have intra-molecular sieve void spaces that are too small to allow formation of these species. The molecular sieves are tested as MTO catalysts at 400 °C, and only the molecular sieves with the CHA topology show MTO activity. Post-reaction analysis of the organic content of each solid material is accomplished by HF acid digestion with subsequent 1H NMR analysis of the extracted hydrocarbon products to confirm the presence of aromatics in the 8MR materials with sufficiently large cages (those with CHA topology), and absence with materials that have smaller void spaces. These data provide further support for the necessity of polymethylbenzene species in the hydrocarbon pool for MTO activity.

Similar content being viewed by others

References

Froment GF, Dehertog WJH, Marchi AJ (1992) In: Spivey JJ (ed) Catalysis, vol 9. The Royal Society of Chemistry, Cambridge, pp 1–64

Dai W, Wang X, Wu G, Guan N, Hunger M, Li L (2011) ACS Catal 1:292–299

Kaiser SW (1985) Using silicoaluminophosphate molecular sieve catalyst. U.S. Patent 4,499,327

Vora B, Chen JQ, Bozzano A, Glover B, Barger P (2009) Catal Today 141:77–83

Olsbye U, Svelle S, Bjørgen M, Beato P, Janssens TVW, Joensen F, Bordiga S, Lillerud KP (2012) Angew Chem Int Ed Engl 51:5810–5831

Hereijgers BP, Bleken F, Nilsen MH, Svelle S, Lillerud K-P, Bjørgen M, Weckhuysen BM, Olsbye U (2009) J Catal 264:77–87

Dahl IM, Kolboe S (1993) Catal Lett 20:329–336

Bjørgen M, Svelle S, Joensen F, Nerlov J, Kolboe S, Bonino F, Palumbo L, Bordiga S, Olsbye U (2007) J Catal 249:195–207

Zhu Q, Kondo JN, Tatsumi T, Inagaki S, Ohnuma R, Kubota Y, Shimodaira Y, Kobayashi H, Domen K (2007) J Phys Chem C 111:5409–5415

Chen D, Moljord K, Fuglerud T, Holmen A (1999) Microporous Mesoporous Mater 29:191–203

Baerlocher C, McCusker LB, Olson DH (2007) Atlas of zeolite framework types, 6 Revised edn. Elsevier, London

Haw JF, Marcus DM (2005) Top Catal 34:41–48

Arstad B, Nicholas JB, Haw JF (2004) J Am Chem Soc 126:2991–3001

Liang J, Li H, Zhao S, Guo W, Wang R, Ying M (1990) Appl Catal 64:31–40

Vora BV, Marker TL, Barger PT, Nilsen HR, Kvisle S, Fuglerud T (1997) Stud Surf Sci Catal 107:87–98

Chen JQ, Bozzano A, Glover B, Fuglerud T, Kvisle S (2005) Catal Today 106:103–107

Zones SI (1985) Zeolite SSZ-13 and its method of preparation. US Patent 4,544,538

Yuen L-T, Zones SI, Harris TV, Gallegos EJ, Auroux A (1994) Microporous Mater 2:105–117

Zhu QJ, Kondo JN, Ohnuma R, Kubota Y, Yamaguchi M, Tatsumi T (2008) Microporous Mesoporous Mater 112:153–161

Bhawe Y, Moliner-Marin M, Lunn JD, Liu Y, Malek A, Davis ME (2012) ACS Catal 2:2490–2495

Schmidt JE, Deimund MA, Davis ME (2014) Chem Mater 26:7099–7105

Baerlocher C, McCusker LB. Database of zeolite structures. http://www.iza-structure.org/databases/. Accessed 3 Dec 2014

Robson H (2001) Verified synthesis of zeolitic materials. Elsevier, Amsterdam

Miller SJ, Process for olefin isomerization. US Patent 6,281,404

Rubin MK (1991) Synthetic crystal MCM-35. US Patent 4,981,663

Campbell BJ, Cheetham AK, Bellussi G, Carluccio L, Perego G, Millini R, Cox DE (1998) Chem Commun 008:1725–1726

Yilmaz B, Müller U, Feyen M, Zhang H, Xiao F-S, De Baerdemaeker T, Tijsebaert B, Jacobs P, De Vos D, Zhang W et al (2012) Chem Commun (Camb) 48:11549–11551

Acknowledgments

The authors would like to thank Chevron Energy and Technology Company and the Dow Chemical Company for each providing partial support for this work. J.E.S. would like to thank the NDSEG for their support through a fellowship. We thank Stacey Zones of Chevron Energy and Technology Company for suggesting that we investigate the suite of materials presented here and for supplying the SAPO-39 material.

Conflict of interest

The authors declare no competing financial interest.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Deimund, M.A., Schmidt, J.E. & Davis, M.E. Effect of Pore and Cage Size on the Formation of Aromatic Intermediates During the Methanol-to-Olefins Reaction. Top Catal 58, 416–423 (2015). https://doi.org/10.1007/s11244-015-0384-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11244-015-0384-y