Abstract

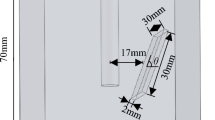

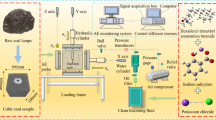

The transport and placement characteristics of proppant in rough fracture is of great significance for optimizing fracturing parameters and making proppant transport to the deep part of fracture for effective support. This paper scans the surface morphology of rock samples after fracturing, generates rough fracture based on the scanned data, and uses high-order interpolation function to generate fracture with different roughness, and establishes a numerical model of proppant transport in different roughness based on Euler-Euler two-phase flow model. The effects of different fracture roughness, fluid velocity, proppant size, proppant density and carrying fluid viscosity on the transport pattern and placement characteristics of proppant were compared and analyzed. The results show that: (1) The complex spatial structure of rough fracture hinders the transport of proppant and makes the placement of proppant in fracture uneven, with the characteristics of tortuous and variable; Compared with smooth fracture, the equilibrium height of proppant in rough fracture is higher, and more settlement at the front end of fracture is easy to cause sand plugging; (2) Higher fluid velocity, smaller density and size are conducive to the transport of proppant in rough fracture, which is not easy to cause sand plugging, and can make proppant be carried to the deep part of fracture for effective support (3) Increasing the viscosity of carrying fluid and reducing the size of proppant can significantly improve the sand carrying performance of fluid, and smaller proppant size can better pass through branch fracture. Compared with changing other process parameters, changing the viscosity of carrying fluid and proppant size has more significant effect. But in the field fracturing process, increasing the viscosity of carrying fluid is easier to achieve, so in the hydraulic fracturing process design, the viscosity of carrying fluid should be considered first, and 70% of dimensionless equilibrium height in rough fracture should be used as the critical point to evaluate sand carrying efficiency. Exceeding 70% is easy to cause sand plugging. Optimize fracturing parameters. It is recommended that fluid velocity should be greater than 0.2 m/s, proppant size should be less than 0.32 mm, proppant density should be less than 2600 kg/m3, and carrying fluid viscosity should be greater than 2 mPa s in field fracturing construction. (4) Proppant is placed in main fracture first in multi-cluster rough branch fracture, and then carried into branch fracture after reaching a certain height. It shows symmetrical distribution in branch fracture. It is suggested that smaller proppant size should be selected first in field fracturing construction process to enter branch fracture for effective support. The research results provide theoretical basis for realizing efficient filling of proppant in the deep part of fracture and optimizing fracturing parameters.

Similar content being viewed by others

Abbreviations

- \(\varphi_{{\text{s}}}\) :

-

Volume fraction of solid phase, %

- \(\varphi_{l}\) :

-

Volume fraction of fluid phase, %

- \(\rho_{{\text{s}}}\) :

-

Solid phase density, dimensionless, kg/m3

- \(\rho_{{\text{l}}}\) :

-

Fluid phase density, dimensionless, kg/m3

- \(\overrightarrow {{{\text{v}}_{{\text{s}}} }}\) :

-

Solid phase velocity, m/s

- \(\overrightarrow {{{\text{v}}_{{\text{l}}} }}\) :

-

Fluid phase velocity, m/s

- p s :

-

Solid phase pressure, Pa

- p l :

-

Fluid phase pressure, Pa

- \(\overrightarrow {{\text{g}}}\) :

-

Acceleration of vectors, m/s2

- \(\tau_{{{\text{s1}}}}\) :

-

Laminar stress in solid phase, N/m2

- \(\tau_{{{\text{s}}2}}\) :

-

Turbulent stress in solid phase, N/m2

- \(\tau_{{{\text{l}}1}}\) :

-

Laminar stress in fluid phase, N/m2

- \(\tau_{{{\text{l}}2}}\) :

-

Turbulent stress in fluid phase, N/m2

- S D :

-

Momentum source equation, dimensionless

- M D :

-

Momentum exchange coefficient between the fluid phase and the solid phase, dimensionless

- F s :

-

Interparticle collision force, N

- k :

-

Turbulent kinetic energy of the continuous phase, m2/s2

- \(\varepsilon\) :

-

Dissipation rate of turbulent kinetic energy in continuous phase, m2/s3

- \(\mu_{t}\) :

-

Viscosity coefficient of the continuous phase, Pa s

- \(\prod k\) :

-

The exchange coefficient between the solid phase and the liquid phase, kg/(m s3)

- \(\prod \varepsilon\) :

-

The exchange coefficient between the solid phase and the liquid phase, kg/(m s3)

- G k,l :

-

The source term of turbulent kinetic energy in continuous phase, kg/(m s3)

- \(\sigma_{{\text{k}}}\) :

-

The turbulent kinetic energy corresponds to a Prandtl number with a value of 1.0, dimensionless

- \(\sigma_{\varepsilon }\) :

-

The turbulent kinetic energy corresponds to a Prandtl number with a value of 1.3, dimensionless

- \(C_{1\varepsilon }\) :

-

The empirical constant is 1.44, dimensionless

- \(C_{2\varepsilon }\) :

-

The empirical constant is 1.92, dimensionless

References

Ban, L.R., Qi, C.Z., Yan, F.Y., Liu, Y., Zhu, C., Tao, Z.G.: A new method for determining the JRC with new roughness parameters. J. China Coal Soc. 44(04), 1059–1065 (2019)

Barton, N., Choubey, V.: The shear strength of rock joints in theory and practice. Rock Mech. Felsmech. M Canique Des Roches 10(1–2), 1–54 (1977)

Di, W.: Transport pattern and placement characteristics of proppant in fractures. Fault-Block Oil Gas Field 26(3), 355–359 (2019)

Ding, Z.L.: Twenty years of Chinese ocean drilling. Chin. Sci. Bull. 63(36), 3866–3867 (2018)

Guo, T.K., Gong, Z.Y., Liu, X.Q., Wang, Z.L., Xu, J.C., Sheng, M., Chen, L., Luo, Z.L.: Numerical simulation of proppant transport and distribution in complex fractures. J. China Univ. Pet. (ed. Nat. Sci.) 46(03), 89–95 (2022)

Hao, L.H.: CFD numerical simulation of proppant settlement and transport in complex fractures. Pet. Ind. Appl. 39(03), 30–32 (2020)

Hou, T.F., Zhang, S.C., Ma, X.F., Li, D., Sun, Y.A.: Effect of proppant settlement patterns on the productivity of shale-gas horizontal wells after the fracturing. Oil Drill. Prod. Technol. 39(05), 638–645 (2017)

Jiang, C.B., Li, Q.: Understanding and field practice of deep shale reservoir stimulation. J. Jianghan Pet. Univ. Staff Workers 33(04), 28–30 (2020)

Jiang, R.Z., Jiang, T.X., Wang, Y.L.: Recent development and prospect of hydraulic fracturing technology. Oil Drill. Prod. Technol. 26(4), 52–57 (2004)

Jiang, T.X., Bian, X.B., Hou, L., Huang, H., Zhang, C., Li, H.Z., Wang, Z.Y.: Experiment on proppant transport and placement behavior in rough fractures. J China Univ. Pet. (ed. Nat. Sci.) 45(06), 95–101 (2021)

Patankar, N.A., Joseph, D.D., Wang, J., Barree, R.D., Conway, M., Asadi, M.: Power pattern correlations for sediment transport in pressure driven channel flows. Int. J. Multiph. Flow 28(8), 1269–1292 (2002)

Sheng, Y.Q., Li, F.X., Zhang, Y., Liu, C.Y., Zhang, X.H.: Analysis of proppant transport and layout in complex fracture network. Pet. Geol. Recovery Effic. 27(05), 134–142 (2020)

Wang, X.: Analysis of factors affecting proppant settlement in fractures. Petrochem. Ind. Technol. 24(3), 292 (2017)

Wan, H.B., Li, T.Z.: Research status and prospect of deposition and transport of propellant in shale pneumatic fracture. Contemp. Chem. Ind. 48(08), 1775–1778 (2019)

Wen, H.T., Yang, R.R., Huang, Z.W., Zheng, Y., Wu, X.G., Hu, X.D.: Numerical simulation of proppant transport in liquid nitrogen fracturing. J. Nat. Gas Sci. Eng. 84, 103657 (2020)

Weng, Q.Z., Luo, M.L., Li, J.N., Li, J.J., Wei, Z.W., Tian, Y.J.: Principle of proppant settlement in fracture. Pet. Geol. Recov. Effic. 16(3), 100–103 (2009)

Weng, D.W., Lei, Q., Xu, Y.: Network fracturing techniques and its application in the field. Acta Petrolei Sinica 32(2), 280–284 (2011)

Wu, Y.H., Wen, Q.Z., Zhang, Y.X., Sun, Q.Q., Zhang, Y.X., Wang, L., Guo, S.T.: Control optimization on proppant spiting. Fault-Block Oil Gas Field 19(05), 662–665 (2012)

Xu, J.H., Wen, S.C.: Gel breaking performance evaluation and field application of clean fracturing fluid for development of low temperature coal bed gas. Contemp. Chem. Ind. 47(03), 520–523 (2018)

Xu, R.Z., Xu, N.: Simulation of transport and sedimentation of proppant in fractures based on FLUENT. Nat Gas Oil 31(03), 46–493 (2013)

Yuan, Q.Q., Zhao, M., Ge, D., Wang, C.: The numerical simulation of sediment scour based on a Eulerian model. J. Harbin Eng. Univ. 40(01), 47–53 (2019)

Zeng, J.S., Dai, C., Fang, S.D., Li, H., Liu, H.: Numerical simulation of proppant transport pattern in intersecting fractures. Fault-Block Oil Gas Field 28(05), 691–695 (2021)

Zhang, C., Wang, Z.Y., Du, K.: Study on proppant transport in rough fractures based on CFD—DEM coupling model. In: Proceedings of the 31th National Conference on Hydrodynamics, 688–701, 2020

Zhang, T., Guo, J.C.: CFD simulation of proppant transport and settling in water fracture treatments. J. Southwest Pet. Univ. (sci. Technol. Ed.) 36(1), 74–82 (2014)

Zheng, Y., Wang, H.Z., Li, G.S., Tian, G.H., Yang, B., Liu, M.S.: Proppant transport characteristics in tortuous fractures induced by supercritical CO2 fracturing. Nat. Gas Ind. 42(03), 71–80 (2022)

Acknowledgements

This study was financially supported by The National Natural Science Foundation of China Youth Science Foundation (No. 52204063) and Science Foundation of China University of Petroleum, Beijing (No. 2462022QZDX006). The authors are grateful for approval to publish this article.

Funding

The authors have not disclosed any funding.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, T., Zhong, P., Li, G. et al. Transport Pattern and Placement Characteristics of Proppant in Different Rough Fractures. Transp Porous Med 149, 251–269 (2023). https://doi.org/10.1007/s11242-023-01965-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11242-023-01965-x