Abstract

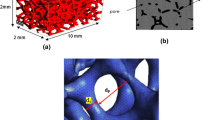

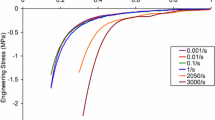

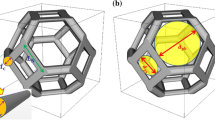

The present study investigates the effects of the geometric properties of porous media on fluid flows and uses a combination of computational fluid dynamics (CFD) and machine learning (ML) methods to develop new models for predicting the coefficients in the Forchheimer equation (ΔP/L = αv + βv2). For this purpose, CFD simulations are performed to assess the effects of foam structural properties on fluid flows for each of the 217 foam types tested. In this research, the Voronoi tessellation method is used to investigate such foam physical properties as porosity, pore diameter, strut diameter, and specific surface area. In all the simulations, air is used as the fluid entering the metallic foams at different superficial velocities but at a constant temperature of 300 K. Pressure gradient as well as Darcy (α) and non-Darcy (β) flow coefficients are then calculated for each foam using the equation and the simulation results. It is shown that the values thus obtained strongly depend on the geometric properties of the porous medium. A second aspect of the study involves resolving the problems of the computation cost due to the complex geometries of foams that result in too many computational grids in the proposed method. This was addressed via machine learning (ML) regression models to develop a continuous model based on foam intrinsic properties. In this approach, models are proposed for estimating α and β coefficients to be used in calculating pressure drop in different metallic foams. The results show that the ridge regularization regression and ordinary least squares are robust models for predicting the coefficients based on foam geometric properties. Moreover, the model is capable of calculating both the values for Reynolds number and friction factor in the continuous range, whereby the flow type can also be determined. Finally, the results obtained from the models indicate the efficacy of the proposed approach for the study of fluid flows in large-scale porous media with minimum errors and satisfactory accuracy.

Similar content being viewed by others

Abbreviations

- d p :

-

Pore diameter (µm)

- d s :

-

Strut diameter (µm)

- d t :

-

Total diameter (pore diameter + strut diameter) (μm)

- P :

-

Pressure (N m−2)

- ΔPL −1 :

-

Pressure gradient (Pa m−1)

- v :

-

Velocity (m s−1)

- \({V}_{\mathrm{p}}\) :

-

Pore volume (m3)

- \({V}_{\mathrm{s}}\) :

-

Solid volume (m3)

- \({V}_{\mathrm{total}}\) :

-

Total volume of the foam (m3)

- L :

-

Foam length (mm)

- \({S}_{0}\) :

-

Specific surface area (m−1)

- \({S}_{\mathrm{s}}\) :

-

Solid surface area (m2)

- α :

-

Darcy flow coefficient (kg m−3 s−1)

- β :

-

Non-Darcy flow coefficient (kg m−4)

- ρ :

-

Density (kg m−3)

- µ :

-

Dynamic viscosity (kg m−1 s−1)

- ε :

-

Porosity

References

Ambrosetti, M., Bracconi, M., Groppi, G., Tronconi, E.: Analytical geometrical model of open cell foams with detailed description of strut-node intersection. Chem. Ing. Tec. 89, 915–925 (2017)

Anuar, F.S., Abdi, I.A., Odabaee, M., Hooman, K.: Experimental study of fluid flow behaviour and pressure drop in channels partially filled with metal foams. Exp. Therm. Fluid Sci. 99, 117–128 (2018)

Ayodele, T.O.: Types of machine learning algorithms. New Adv. Mach. Learn. 3, 19–48 (2010)

Bhattacharya, A., Calmidi, V.V., Mahajan, R.L.: Thermophysical properties of high porosity metal foams. Int. J. Heat Mass Transf. 45, 1017–1031 (2002)

Bishop, C.M., Nasrabadi, N.M.: Pattern Recognition and Machine Learning. Springer, New York (2006)

Bodla, K.K., Murthy, J.Y., Garimella, S.V.: Microtomography-based simulation of transport through open-cell metal foams. Numer. Heat Transf. Part A Appl. 58, 527–544 (2010)

Boomsma, K., Poulikakos, D., Ventikos, Y.: Simulations of flow through open cell metal foams using an idealized periodic cell structure. Int. J. Heat Fluid Flow 24, 825–834 (2003)

Buonomo, B., Diana, A., Manca, O., Nardini, S.: Numerical investigation on natural convection in horizontal channel partially filled with aluminium foam and heated from above. J. Phys. 923, 012049 (2017)

Crosnier, S., R. Riva, B. Bador, and V. Blet.: Modelling of gas flow through metallic foams. (2003)

Dabbaghi, S., et al.: Numerical simulation of fluid flow through metallic foams: a general correlation for different length sizes and pore characteristics. Spec. Top. Rev. Porous Media Int. J. 12(1), 73–93 (2021)

De Carvalho, T.P., Morvan, H.P., Hargreaves, D.M., Oun, H., Kennedy, A.: Pore-scale numerical investigation of pressure drop behaviour across open-cell metal foams. Transp. Porous Media 117, 311–336 (2017)

Dietrich, B., Schabel, W., Kind, M., Martin, H.: Pressure drop measurements of ceramic sponges—determining the hydraulic diameter. Chem. Eng. Sci. 64, 3633–3640 (2009)

Du, S., Li, M.J., Ren, Q., Liang, Q., He, Y.L.: Pore-scale numerical simulation of fully coupled heat transfer process in porous volumetric solar receiver. Energy 140, 1267–1275 (2017)

Edouard, D., Lacroix, M., Huu, C.P., Luck, F.: Pressure drop modeling on SOLID foam: state-of-the art correlation. Chem. Eng. J. 144, 299–311 (2008)

Fly, A., Butcher, D., Meyer, Q., Whiteley, M., Spencer, A., Kim, C., Chen, R.: Characterisation of the diffusion properties of metal foam hybrid flow-fields for fuel cells using optical flow visualisation and X-ray computed tomography. J. Power Sour. 395, 171–178 (2018)

Fourie, J.G., Du Plessis, J.P.: Pressure drop modelling in cellular metallic foams. Chem. Eng. Sci. 57, 2781–2789 (2002)

Gancarczyk, A., Sindera, K., Iwaniszyn, M., Piątek, M., Macek, W., Jodłowski, P.J., Kołodziej, A.: Metal foams as novel catalyst support in environmental processes. Catalysts 9, 587 (2019)

Garrido, G.I., Patcas, F.C., Lang, S., Kraushaar-Czarnetzki, B.: Mass transfer and pressure drop in ceramic foams: a description for different pore sizes and porosities. Chem. Eng. Sci. 63, 5202–5217 (2008)

Giani, L., Groppi, G., Tronconi, E.: Mass-transfer characterization of metallic foams as supports for structured catalysts. Ind. Eng. Chem. Res. 44, 4993–5002 (2005)

Hu, C., Sun, M., Xie, Z., Yang, L., Song, Y., Tang, D., Zhao, J.: Numerical simulation on the forced convection heat transfer of porous medium for turbine engine heat exchanger applications. Appl. Therm. Eng. 180, 115845 (2020)

Hutcheson, G. D.: Ordinary least-squares regression. In: Moutinho, L., and Hutcheson, G.D. (eds.) The SAGE Dictionary of Quantitative Management Research, pp. 224-228 (2011)

Inayat, A., Klumpp, M., Lämmermann, M., Freund, H., Schwieger, W.: Development of a new pressure drop correlation for open-cell foams based completely on theoretical grounds: taking into account strut shape and geometric tortuosity. Chem. Eng. J. 287, 704–719 (2016)

Innocentini, M.D., Salvini, V.R., Macedo, A., Pandolfelli, V.C.: Prediction of ceramic foams permeability using Ergun’s equation. Mater. Res. 2, 283–289 (1999)

Jafarizade, A., Panjepour, M., Meratian, M., Emami, M.D.: Numerical simulation of gas/solid heat transfer in metallic foams: a general correlation for different porosities and pore sizes. Transp. Porous Media 127, 481–506 (2019)

Jones, W.P., Launder, B.E.: The prediction of laminarization with a two-equation model of turbulence. Int. J. Heat Mass Transf. 15, 301–314 (1972)

Kaviany, M.: Principles of Heat Transfer in Porous Media. Springer, Cham (2012)

Khayargoli, P., Loya, V., Lefebvre, L. P., & Medraj, M.: The impact of microstructure on the permeability of metal foams. In CSME forum, pp. 220–228 (2004)

Khosravi, A., Pabon, J.J.G., Koury, R.N.N., Machado, L.: Using machine learning algorithms to predict the pressure drop during evaporation of R407C. Appl. Therm. Eng. 133, 361–370 (2018)

Kim, S.Y., Kang, B.H., Kim, J.H.: Forced convection from aluminum foam materials in an asymmetrically heated channel. Int. J. Heat Mass Transf. 44, 1451–1454 (2001)

Kopanidis, A., Theodorakakos, A., Gavaises, E., Bouris, D.: 3D numerical simulation of flow and conjugate heat transfer through a pore scale model of high porosity open cell metal foam. Int. J. Heat Mass Transf. 53, 2539–2550 (2010)

Kotresha, B., & Gnanasekaran, N.: Numerical simulations of fluid flow and heat transfer through aluminum and copper metal foam heat exchanger–a comparative study. Heat Transf. Eng. (2019)

Kumar, P., & Topin, F.: State-of-the-art of pressure drop in open-cell porous foams: review of experiments and correlations. J. Fluids Eng. 139, (2017)

Kumar, P., Topin, F.: Investigation of fluid flow properties in open cell foams: Darcy and weak inertia regimes. Chem. Eng. Sci. 116, 793–805 (2014)

Kuruneru, S.T.W., Vafai, K., Sauret, E., Gu, Y.: Application of porous metal foam heat exchangers and the implications of particulate fouling for energy-intensive industries. Chem. Eng. Sci. 228, 115968 (2020)

Lacroix, M., Nguyen, P., Schweich, D., Huu, C.P., Savin-Poncet, S., Edouard, D.: Pressure drop measurements and modeling on SiC foams. Chem. Eng. Sci. 62, 3259–3267 (2007)

Launder, B. E., & Spalding, D. B.: The numerical computation of turbulent flows. In: Numerical prediction of flow, heat transfer, turbulence and combustion, pp. 96–116 (1983)

Liu, J.F., Wu, W.T., Chiu, W.C., Hsieh, W.H.: Measurement and correlation of friction characteristic of flow through foam matrixes. Exp. Thermal Fluid Sci. 30, 329–336 (2006)

Macdonald, I.F., El-Sayed, M.S., Mow, K., Dullien, F.A.L.: Flow through porous media-the Ergun equation revisited. Ind. Eng. Chem. Fundam. 18, 199–208 (1979)

Magnico, P.: Analysis of permeability and effective viscosity by CFD on isotropic and anisotropic metallic foams. Chem. Eng. Sci. 64, 3564–3575 (2009)

Mahjoob, S., Vafai, K.: A synthesis of fluid and thermal transport models for metal foam heat exchangers. Int. J. Heat Mass Transf. 51, 3701–3711 (2008)

Mohammed, H.I., Giddings, D.: Multiphase flow and boiling heat transfer modelling of nanofluids in horizontal tubes embedded in a metal foam. Int. J. Therm. Sci. 146, 106099 (2019)

Moreira, E.A., Coury, J.R.: The influence of structural parameters on the permeability of ceramic foams. Braz. J. Chem. Eng. 21, 23–33 (2004)

Nie, Z., Lin, Y., Tong, Q.: Modeling structures of open cell foams. Comput. Mater. Sci. 131, 160–169 (2017a)

Nie, Z., Lin, Y., Tong, Q.: Numerical investigation of pressure drop and heat transfer through open cell foams with 3D Laguerre-Voronoi model. Int. J. Heat Mass Transf. 113, 819–839 (2017b)

Owen, A.B.: A robust hybrid of lasso and ridge regression. Contemp. Math. 443, 59–72 (2007)

Poureslami, P., Siavashi, M., Moghimi, H., Hosseini, M.: Pore-scale convection-conduction heat transfer and fluid flow in open-cell metal foams: a three-dimensional multiple-relaxation time lattice Boltzmann (MRT-LBM) solution. Int. Commun. Heat Mass Transfer 126, 105465 (2021)

Ranstam, J., Cook, J.A.: LASSO regression. J. Br. Surg. 105, 1348–1448 (2018)

Richardson, J.T., Peng, Y., Remue, D.: Properties of ceramic foam catalyst supports: pressure drop. Appl. Catal. A 204, 19–32 (2000)

Sedighi, M., Padilla, R.V., Lake, M., Rose, A., Lim, Y.Y., Novak, J.P., Taylor, R.A.: Design of high-temperature atmospheric and pressurised gas-phase solar receivers: a comprehensive review on numerical modelling and performance parameters. Sol. Energy 201, 701–723 (2020)

Segal, M. R.: Machine learning benchmarks and random forest regression. (2004)

Sidiropoulou, M.G., Moutsopoulos, K.N., Tsihrintzis, V.A.: Determination of Forchheimer equation coefficients a and b. Hydrol. Process. Int. J. 21, 534–554 (2007)

Straughan, B.: Structure of the dependence of Darcy and Forchheimer coefficients on porosity. Int. J. Eng. Sci. 48, 1610–1621 (2010)

Tadrist, L., Miscevic, M., Rahli, O., Topin, F.: About the use of fibrous materials in compact heat exchangers. Exp. Thermal Fluid Sci. 28, 193–199 (2004)

Tawfik, S.A., Isayev, O., Spencer, M.J., Winkler, D.A.: Predicting thermal properties of crystals using machine learning. Adv. Theory Simul. 3, 1900208 (2020)

Tian, J., Qi, C., Sun, Y., Yaseen, Z.M., Pham, B.T.: Permeability prediction of porous media using a combination of computational fluid dynamics and hybrid machine learning methods. Eng. Comput. 37, 3455–3471 (2021)

Wejrzanowski, T., Skibinski, J., Szumbarski, J., Kurzydlowski, K.J.: Structure of foams modeled by Laguerre-Voronoi tessellations. Comput. Mater. Sci. 67, 216–221 (2013)

Wu, Z., Caliot, C., Bai, F., Flamant, G., Wang, Z., Zhang, J., Tian, C.: Experimental and numerical studies of the pressure drop in ceramic foams for volumetric solar receiver applications. Appl. Energy 87, 504–513 (2010)

Xu, W., Zhang, H., Yang, Z., Zhang, J.: Numerical investigation on the flow characteristics and permeability of three-dimensional reticulated foam materials. Chem. Eng. J. 140, 562–569 (2008)

Yin, Y., Qu, Z.G., Zhang, T., Zhang, J.F., Wang, Q.Q.: Three-dimensional pore-scale study of methane gas mass diffusion in shale with spatially heterogeneous and anisotropic features. Fuel 273, 117750 (2020)

Yin, Y., Qu, Z., Zhu, C., Zhang, J.: Visualizing gas diffusion behaviors in three-dimensional nanoporous media. Energy Fuels 35, 2075–2086 (2021)

Zafari, M., Panjepour, M., Emami, M.D., Meratian, M.: Microtomography-based numerical simulation of fluid flow and heat transfer in open cell metal foams. Appl. Therm. Eng. 80, 347–354 (2015)

Zafari, M., Panjepour, M., Meratian, M., & Emami, M. D.: CFD simulation of forced convective heat transfer by tetrakaidecahedron model in metal foams. J. Porous Media, 19, (2016)

Zhang, L., Chen, H., Tao, X., Cai, H., Liu, J., Ouyang, Y., Du, Y.: Machine learning reveals the importance of the formation enthalpy and atom-size difference in forming phases of high entropy alloys. Mater. Des. 193, 108835 (2020)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jafarizadeh, A., Ahmadzadeh, M., Mahmoudzadeh, S. et al. A New Approach for Predicting the Pressure Drop in Various Types of Metal Foams Using a Combination of CFD and Machine Learning Regression Models. Transp Porous Med 147, 59–91 (2023). https://doi.org/10.1007/s11242-022-01895-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11242-022-01895-0