Abstract

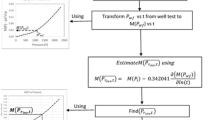

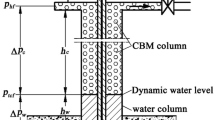

Coalbed methane (CBM) reservoirs contain gas molecules in adsorbed state into the solid matrix of coal. The pressure depletion in CBM reservoir causes the matrix gas to desorb into the cleat system which leads to matrix shrinkage. The pore volume of the cleat network changes as coal matrix shrinks. Consequently, cleat porosity and permeability of reservoir change as reservoir pressure depletes. The change in cleat porosity and permeability due to shrinkage of coal matrix with depletion of reservoir pressure invalidates the underlying assumptions made in the derivation of diffusivity equation. Under the conditions of changing porosity and permeability, the utility of the standard method of inflow performance relationship (IPR), paired with \(\frac{P}{Z^{*}}\) method suggested by King (in: SPE Annual Technical Conference and Exhibition, New Orleans, 1990), for performance prediction diminishes. In this paper, an effort has been made to predict reservoir performance of such CBM reservoirs with an alternative approach. The method suggested by Upadhyay and Laik (Transp Porous Media, 2017. doi:10.1007/s11242-016-0816-6) has been leveraged to describe pseudo-steady-state flow in the form of a new equation that relates stress-dependent pseudo-pressure function with time. The analytical equation derived in this paper is useful in predicting reservoir pressure and flowing bottom hole pressure of a CBM well under the situation when coal matrix shrinks below desorption pressure. The paper aims to predict production performance of CBM reservoirs producing under the influence of matrix shrinkage effect with an approach alternative to conventional IPR approach paired with \(\frac{P}{Z^{*}}\) method. The results of this analytical solution have been validated with the help of numerical simulator CMG–GEM as well as in-field production data. The equations and workflow suggested in this paper can be easily implemented in spreadsheet applications like Microsoft Excel tools.

Similar content being viewed by others

Abbreviations

- \(A_\mathrm{m} \) :

-

Matrix shrinkage compressibility (\(\mathrm{atm}^{-1}\))

- \(B_\mathrm{g} \) :

-

Gas formation volume factor (rcc/scc)

- \(C_\mathrm{f} \) :

-

Pore volume compressibility (\(\mathrm{atm}^{-1}\))

- \(C_\mathrm{g} \) :

-

Gas compressibility (\(\mathrm{atm}^{-1}\))

- \(C_\mathrm{s} \) :

-

Sorption compressibility (\(\mathrm{atm}^{-1}\))

- \(C_\mathrm{t} \) :

-

Total compressibility (\(\mathrm{atm}^{-1}\))

- \(C_\mathrm{ti} \) :

-

Total compressibility at initial reservoir pressure \(\left( {P_\mathrm{i} } \right) \) (\(\mathrm{atm}^{-1}\))

- \(G_\mathrm{c}\) :

-

Gas content in coal matrix (cc/g)

- h:

-

Reservoir thickness (cm)

- \(k_\mathrm{i} \) :

-

Initial fracture permeability (Darcy)

- k :

-

Average fracture permeability @ pressure P (Darcy)

- K :

-

Bulk modulus (atm)

- \(M_\mathrm{i} \) :

-

Mass flow rate IN (g/sec)

- \(M_\mathrm{o} \) :

-

Mass flow rate OUT (g/sec)

- \(M_\mathrm{d} \) :

-

Mass rate of gas desorption (g/sec)

- \(M_\mathrm{a} \) :

-

Mass rate of accumulation (g/sec)

- \(M\left( P \right) \) :

-

Pseudo-pressure function (\(\mathrm{atm}^{2}/\mathrm{cp}\))

- M :

-

Constrained axial modulus (atm)

- \(P_\mathrm{sc} \) :

-

Pressure at standard condition (atm)

- \(P_\mathrm{i} \) :

-

Initial reservoir pressure (atm)

- P:

-

Reservoir pressure (atm)

- \(P_\mathrm{wf} \) :

-

Flowing bottom hole pressure (atm)

- \(P_\mathrm{L} \) :

-

Langmuir pressure (atm)

- q :

-

Flow rate at reservoir condition (cc/sec)

- \(q_\mathrm{sc}\) :

-

Flow rate at standard condition (cc/sec)

- \(r_\mathrm{e}\) :

-

Outer boundary radius (cm)

- \(r_\mathrm{w}\) :

-

Wellbore radius (cm)

- S :

-

Mechanical skin (\({-}\))

- \(t_\mathrm{pseudo} \) :

-

Pseudo-time (constant rate solution) (sec)

- \(t_\mathrm{pseudo}^*\) :

-

Pseudo-time (constant pressure solution) (sec)

- \(T_\mathrm{sc} \) :

-

Temperature at standard condition (\(^{\circ }\hbox {R}\))

- T :

-

Reservoir temperature (\(^{\circ }\hbox {R}\))

- V :

-

Volume of cylinder (cc)

- \(V_\mathrm{L} \) :

-

Langmuir Volume (cc/g)

- \(\alpha \) :

-

Constant of proportionality (k and \(\varphi \) relation) (Darcy)

- \(\beta \) :

-

Geomechanical grouping parameter (Dimensionless)

- \(\varepsilon _L \) :

-

Volumetric strain at infinite pressure (Dimensionless)

- \(\mu \) :

-

Gas viscosity (cp)

- \(\rho \) :

-

Gas density at pressure P (g/cc)

- \(\rho _\mathrm{b} \) :

-

Bulk density of coal (g/cc)

- \(\rho _\mathrm{sc} \) :

-

Gas density at standard condition (g/cc)

- \(\upnu \) :

-

Poisson’s ratio (Dimensionless)

- \(\varphi \) :

-

Average fracture porosity at pressure P (Dimensionless)

- \(\varphi _\mathrm{i} \) :

-

Initial fracture porosity (Dimensionless)

References

Al-Hussainy, R., Ramey Jr., H.J., Crawford, P.B.: The flow of real gases through porous media. J. Pet. Technol. SPE-1243-A-PA, 625–636 (1966)

Burgoyne, M., Shrivastava, R.: A practical workflow for characterizing stress-dependent behaviour of coal from changes in well productivity. J. Nat. Gas Sci. Eng. 33, 1025–1045 (2016)

Jensen, D., Smith, L. K., 1997. : A practical approach to coalbed methane reserve prediction using a modified material balance technique. In: International Coalbed Methane Symposium, Alabama. Paper 9765

King, G.R.: material balance techniques for coal seam and devonian shale gas reservoirs. In: SPE Annual Technical Conference and Exhibition, New Orleans, 23–26 September. SPE 20730 (1990)

Palmer, I., Mansoori, J.: How permeability depends on stress and pore pressure in coalbeds: a new model. In: SPE Reservoir Evaluation and Engineering, pp. 539–544. SPE-52607-PA (1998)

Raghavan, R., Scorer, J.D.T., Miller, F.G.: An investigation by numerical methods of the effect of pressure-dependent rock and fluid properties on well flow tests. Soc. Pet. Eng. J. 12, 267 (1972)

Reiss, L.H.: The Reservoir Engineering Aspects of Fractured Formations. Editions Technip, France (1980)

Seidle, J.P.: A modified p/Z method for coal wells. In: SPE Rocky Mountain Regional Meeting, Gillette, Wyoming, USA, 15-18 May. SPE 55605 (1999)

Shi, J.Q., Durucan, S.: A model for changes in coalbed permeability during primary and enhanced methane recovery. SPE Reserv Eval. Eng. Soc. Pet. Eng. 8, 291 (2005)

Stewart, G.: Transient testing of CBM wells. In: Proceedings of the 2010 Asia Pacific Oil and Gas Conference and Exhibition in Brisbane, Brisbane, Queensland, 18–20 October 2010, SPE-133356 (2010)

Upadhyay, R., Laik, S.: A computational approach to determine average reservoir pressure in a coalbed methane (CBM) well flowing under dominant matrix shrinkage effect. Transp. Porous Media (2017). doi:10.1007/s11242-016-0816-6

Acknowledgements

We express our gratitude to Computer Modelling Group (CMG) which has generously donated the reservoir simulation software to our institute Indian School of Mines for academic purposes. We have used the CMG–GEM numerical simulator to validate the results of the analytical model derived in this paper. We also express our gratitude to data analysis and graphing software “Origin.” The evaluation license version of the software has been used to generate relevant graphs in this paper.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Appendices

Appendix 1: Comparison of Results—CMG–GEM Simulator Versus Analytical Model

See Figs. 6, 7, 8, 9, 10, 11, 12 and 13.

Appendix 2: Comparison of Results—Field Data Versus Analytical Model

Well-1: Comparison of observed pressure data with analytical solution. The early-time pressure solutions are not matching with the observed pressures. The reason is attributed to the minimal water production from Well-1. The initial water production from Well-1 includes frac flow back fluid volumes. The analytical equation generated in this paper has an underlying assumption that water production is negligible. The initial period match is influenced by minimal observed water production. The match gets better in the later period of production life when Well-1 water production reduces to negligible range bringing consistency with the analytical equation underlying assumption

Well-2: Comparison of observed pressure data with analytical solution. The early-time pressure solutions are not matching with the observed pressures. The data availability on \(P_\mathrm{wf}\) is limited during early production life. However, production tests done on Well-2 during initial periods suggest minimal water production. Therefore, initial period pressure match with analytical solution is likely to be disturbed

Well-3: Comparison of observed pressure data with analytical solution. The early-time pressure solutions are not matching with the observed pressures. The reason is attributed to the minimal water production from Well-3. The initial water production from Well-3 includes frac flow back fluid volumes. The analytical equation generated in this paper has underlying assumption that water production is negligible. The initial period match is influenced by minimal observed water production. The match gets better in the later period of production life when Well-1 water production reduces to negligible range bringing consistency with the analytical equation underlying assumption

Rights and permissions

About this article

Cite this article

Upadhyay, R., Laik, S. An Alternative Approach to Predicting Reservoir Performance in a Coalbed Methane (CBM) Well Flowing Under Dominant Matrix Shrinkage Effect. Transp Porous Med 119, 649–672 (2017). https://doi.org/10.1007/s11242-017-0904-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11242-017-0904-2