Abstract

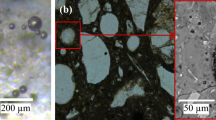

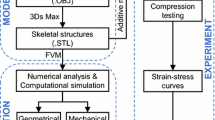

The subject of this study concerns a method of manufacture of porous media for which the solid matrix is capable of experiencing deformation under the influence of the flow field. Conventionally, the matrix design parameters, elasticity and pore geometry, cannot be precisely controlled and the choice of parameters is limited to existing available media. Here a solution is provided that uses an indirect solid-free form fabrication process that combines 3D Printing with an infused Polydimethylsiloxane elastomer to provide a highly deformable matrix with controlled pore architecture. The manufacturing method is presented in detail. Local microscopy analysis of the manufactured matrix shows that the method has a high capability to accurately create pore structures at length scales as low as 0.75 mm. Experimental flow measurements further validate that the intended pore geometry is able to be reproduced in highly deformable matrices. The experimentally determined permeability of the deformable matrix is determined to agree with the intended within 95 %.

Similar content being viewed by others

References

Beavers, G., Hajji, A., Sparrow, E.: Fluid flow through a class of highly-deformable porous media. Part I: experiments with air. J. Fluids Eng. 103, 432 (1981a)

Beavers, G., Wittenberg, K., Sparrow, E.: Fluid flow through a class of highly-deformable porous media. Part II: experiments with water. J. Fluids Eng. 103, 440 (1981b)

Biot, M.A.: Consolidation settlement under a rectangular load distribution. J. Appl. Phys 12(5), 426–430 (1941)

Biot, M.A., Clingan, F.: Consolidation settlement of a soil with an impervious top surface. J. Appl. Phys. 12(7), 578–581 (1941)

Boulos, M., Jomaa, W., Sommier, A., Bruneau, D.: An experimental method of characterization of deformable porous media. In: EPJ Web of Conferences, 25, pp. 01006. EDP Sciences, France (2012)

Bourell, D., Beaman, J., Marcus, H., Barlow, J.: Solid freeform fabrication an advanced manufacturing approach. In: Proceedings of the SFF Symposium, pp. 1–7 (1990)

Cao, Y., Chen, S., Meir, A.J.: Steady flow in a deformable porous medium. Math. Methods Appl. Sci. 37(7), 1029–1041 (2014)

Choi, J.W., Kim, H.C., Wicker, R.: Multi-material stereolithography. J. Mater. Process. Technol. 211(3), 318–328 (2011)

Cowin, S.C.: Bone poroelasticity. J. Biomech. 32(3), 217–238 (1999)

Geoghegan, P., Buchmann, N., Spence, C., Moore, S., Jermy, M.: Fabrication of rigid and flexible refractive-index-matched flow phantoms for flow visualisation and optical flow measurements. Exp. Fluids 52(5), 1331–1347 (2012)

Gross, J., Scherer, G.W.: Dynamic pressurization: novel method for measuring fluid permeability. J. Non-Cryst. Solids 325(1), 34–47 (2003)

Harris, L.D., Kim, B.S., Mooney, D.J.: Open pore biodegradable matrices formed with gas foaming. J. Biomed. Mater. Res. 42(3), 396–402 (1998)

Hollister, S.J.: Porous scaffold design for tissue engineering. Nat. Mater. 4(7), 518–524 (2005)

Hutmacher, D.W., Sittinger, M., Risbud, M.V.: Scaffold-based tissue engineering: rationale for computer-aided design and solid free-form fabrication systems. Trends Biotechnol. 22(7), 354–362 (2004)

Ivanchenko, O., Sindhwani, N., Linninger, A.: Experimental techniques for studying poroelasticity in brain phantom gels under high flow microinfusion. J. Biomech. Eng. 132(5), 051008 (2010)

Johnston, I.D., McCluskey, D.K., Tan, C.K.L., Tracey, M.C.: Mechanical characterization of bulk Sylgard 184 for microfluidics and microengineering. J. Micromech. Microeng. 24(3), 035017 (2014). doi:10.1088/0960-1317/24/3/035017

Kalita, S.J., Bose, S., Hosick, H.L., Bandyopadhyay, A.: Development of controlled porosity polymer-ceramic composite scaffolds via fused deposition modeling. Mater. Sci. Eng. C 23(5), 611–620 (2003)

Khan, I.: Direct numerical simulation and analysis of saturated deformable porous media. Ph.D. thesis, Georgia Institute of Technology (2010)

Khanafer, K., Duprey, A., Schlicht, M., Berguer, R.: Effects of strain rate, mixing ratio, and stress–strain definition on the mechanical behavior of the polydimethylsiloxane (pdms) material as related to its biological applications. Biomed. Microdevices 11(2), 503–508 (2009)

Klempner, D., Sendijarevi’c, V., Aseeva, R.M.: Handbook of Polymeric Foams and Foam Technology. Hanser Verlag, Munich (2004)

Kruth, J.P., Wang, X., Laoui, T., Froyen, L.: Lasers and materials in selective laser sintering. Assem. Autom. 23(4), 357–371 (2003)

Leong, K., Cheah, C., Chua, C.: Solid freeform fabrication of three-dimensional scaffolds for engineering replacement tissues and organs. Biomaterials 24(13), 2363–2378 (2003)

Li, J.P., Habibovic, P., van den Doel, M., Wilson, C.E., de Wijn, J.R., van Blitterswijk, C.A., de Groot, K.: Bone ingrowth in porous titanium implants produced by 3d fiber deposition. Biomaterials 28(18), 2810–2820 (2007)

Liu, X., Ma, P.X.: Phase separation, pore structure, and properties of nanofibrous gelatin scaffolds. Biomaterials 30(25), 4094–4103 (2009)

Markert, B.: A constitutive approach to 3-d nonlinear fluid flow through finite deformable porous continua. Transp. Porous Media 70(3), 427–450 (2007)

Mata, A., Fleischman, A.J., Roy, S.: Characterization of polydimethylsiloxane (pdms) properties for biomedical micro/nanosystems. Biomed. Microdevices 7(4), 281–293 (2005)

Melchels, F.P., Feijen, J., Grijpma, D.W.: A review on stereolithography and its applications in biomedical engineering. Biomaterials 31(24), 6121–6130 (2010)

Mikos, A.G., Herring, S.W., Ochareon, P., Elisseeff, J., Lu, H.H., Kandel, R., Schoen, F.J., Toner, M., Mooney, D., Atala, A., et al.: Engineering complex tissues. Tissue Eng. 12(12), 3307–3339 (2006)

Mills, N.: Polymer foams handbook: engineering and biomechanics applications and design guide. Butterworth-Heinemann, Oxford (2007)

Nazarov, R., Jin, H.J., Kaplan, D.L.: Porous 3-d scaffolds from regenerated silk fibroin. Biomacromolecules 5(3), 718–726 (2004)

Nguyen, T.L., Staiger, M.P., Dias, G.J., Woodfield, T.B.: A novel manufacturing route for fabrication of topologically-ordered porous magnesium scaffolds. Adv. Eng. Mater. 13(9), 872–881 (2011)

Sauter, T., Lützow, K., Schossig, M., Kosmella, H., Weigel, T., Kratz, K., Lendlein, A.: Shape-memory properties of polyetherurethane foams prepared by thermally induced phase separation. Adv. Eng. Mater. 14(9), 818–824 (2012)

Schneider, F., Draheim, J., Kamberger, R., Wallrabe, U.: Process and material properties of polydimethylsiloxane (pdms) for optical mems. Sens. Actuators A 151(2), 95–99 (2009)

Schneider, F., Fellner, T., Wilde, J., Wallrabe, U.: Mechanical properties of silicones for mems. J. Micromech. Microeng. 18(6), 065,008 (2008)

Schrefler, B.A., Scotta, R.: A fully coupled dynamic model for two-phase fluid flow in deformable porous media. Comput. Methods Appl. Mech. Eng. 190(24), 3223–3246 (2001)

Siddique, J., Anderson, D., Bondarev, A.: Capillary rise of a liquid into a deformable porous material. Phys. Fluids 21(1), 013106 (2009)

Tan, K., Chua, C., Leong, K., Cheah, C., Cheang, P., Abu Bakar, M., Cha, S.: Scaffold development using selective laser sintering of polyetheretherketone-hydroxyapatite biocomposite blends. Biomaterials 24(18), 3115–3123 (2003)

Williams, J.M., Adewunmi, A., Schek, R.M., Flanagan, C.L., Krebsbach, P.H., Feinberg, S.E., Hollister, S.J., Das, S.: Bone tissue engineering using polycaprolactone scaffolds fabricated via selective laser sintering. Biomaterials 26(23), 4817–4827 (2005)

Woodfield, T.B., Malda, J., De Wijn, J., Peters, F., Riesle, J., van Blitterswijk, C.A.: Design of porous scaffolds for cartilage tissue engineering using a three-dimensional fiber-deposition technique. Biomaterials 25(18), 4149–4161 (2004)

Zein, I., Hutmacher, D.W., Tan, K.C., Teoh, S.H.: Fused deposition modeling of novel scaffold architectures for tissue engineering applications. Biomaterials 23(4), 1169–1185 (2002)

Zhang, X., Jiang, X., Sun, C.: Micro-stereolithography of polymeric and ceramic microstructures. Sens. Actuators A Phys. 77(2), 149–156 (1999)

Acknowledgments

This study was completed through funding provided by the Technische Universitt Hamburg-Hamburg and the University of Canterbury. The authors gratefully acknowledge Liam Clark and Oliver Coullman for their kind collaboration on experimental tests, Mr. Mike Flaws and Mr. David Read for technical assistance. The work was supported in part by the Marsden Fund Council from Government funding, administered by the Royal Society of New Zealand

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Munro, B., Becker, S., Uth, M.F. et al. Fabrication and Characterization of Deformable Porous Matrices with Controlled Pore Characteristics. Transp Porous Med 107, 79–94 (2015). https://doi.org/10.1007/s11242-014-0426-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11242-014-0426-0