Abstract

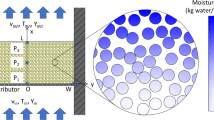

Several modern modelling techniques are presented as tools for drying science and technology, namely pore networks, discrete element method and population balances. After first presenting results from their own research, the authors indicate what future contributions to a better understanding of the drying process at different levels—single porous particles, agitated and fluidised beds—may be expected.

Similar content being viewed by others

Abbreviations

- A :

-

Pore throat cross section [m2]

- c p :

-

Heat capacity [kJ kg−1 K−1]

- f :

-

Number density [m−3 kg−1]

- G :

-

Rate of drying/wetting [kg s−1]

- L :

-

Capillary or pore throat length [m]

- l :

-

Amount of liquid [kg]

- \(\dot{M}\) :

-

Mass flow rate [kg s−1]

- \(\tilde{M}\) :

-

Molar mass [kg kmol−1]

- m l :

-

Liquid mass density [kg−3]

- N mix :

-

Mixing number [–]

- n :

-

Rotational frequency [s−1]

- n :

-

Number density [s−1] or [m−3]

- \(\dot{n}\) :

-

Number flow rate [s−2]

- \(\tilde{R}\) :

-

Ideal gas constant [kJ kmol−1 K−1]

- p :

-

Pressure [Pa]

- r :

-

Radius [m]

- r 0 :

-

Mean radius [m]

- s :

-

Meniscus position [m]

- T :

-

Absolute temperature [K]

- t :

-

Time [s]

- t mix :

-

Revolution time [s]

- t R :

-

Mixing time [s]

- v :

-

Particle volume [m3]

- z :

-

Space coordinate [m]

- Greek symbols :

-

- α:

-

Heat transfer coefficient [W m−2 K−1]

- β:

-

Mass transfer coefficient [m s−1]

- β:

-

Agglomeration kernel [s−1]

- δ:

-

Binary diffusion coefficient [m2 s−1]

- ζ:

-

Dimensionless position [–]

- η:

-

Dynamic viscosity [Pa s]

- λ:

-

Thermal conductivity [Wm−1 K−1]

- \(\dot{\nu}\) :

-

Dimensionless drying rate [–]

- ρ:

-

Density [kg m−3]

- σ:

-

Surface tension [N m−1]

- σ0 :

-

Radius standard deviation [m]

- τ:

-

Age of particle [s]

- ψ:

-

Porosity [–]

- Subscripts :

-

- bed:

-

(Penetration into) Bed

- I:

-

First drying period

- v:

-

Vapour

- ws:

-

Wall-to-bed

References

Bramley A.S., Hounslow M.J., Ryall R.L. (1996). Aggregation during precipitation from solution: A method for extracting rates from experimental data. J. Colloid Interface Sci. 183:155–165

Burgschweiger, J.: Modellierung des statischen und dynamischen Verhaltens von kontinuierlich betriebenen Wirbelschichttrocknern. Dissertation, Universität Magdeburg, VDI-Verlag, Reihe 3, Nr. 665 (2000)

Burgschweiger J., Tsotsas E. (2002). Experimental investigation and modelling of continuous fluidized bed drying under steady-state and dynamic conditions. Chem. Eng. Sci. 57:5021–5038

Cundall P.A., Strack O.D.L. (1979). A discrete numerical model for granular assemblies. Geotechnique 29:47–65

Hounslow M.J., Pearson J.M.K., Instone T. (2001). Tracer studies of high shear granulation: II. Population balance modeling. AIChE J. 47:1984–1999

Huinink H.P., Pel L., Michels M.A.J., Prat M. (2002). Drying processes in the presence of temperature gradients—pore-scale modelling. Eur. Phys. J. E. 9:487–498

Irawan, A., Metzger, T., Tsotsas, E.: Pore network modelling of drying: combination with a boundary layer model to capture the first drying period. Proc. 7th WCCE, Glasgow, United Kingdom (2005)

Kwapinska, M., Saage, G., Tsotsas, E.: On the way from penetration models to discrete element simulations of contact dryers. XI Polish Drying Symposium, Poznan, Poland (2005)

Kwapinska M., Saage G., Tsotsas E. (2006). Mixing of particles in rotary drums: A comparison of discrete element simulations with experimental results and penetration models for thermal processes. Powder Technol. 161:69–78

Laurindo J.B., Prat M. (1998). Numerical and experimental network study of evaporation in capillary porous media. Chem. Eng. Sci. 53:2257–2269

Metzger T., Tsotsas E. (2005). Influence of pore size distribution on drying kinetics: a simple capillary model. Drying Technol. 23:1797–1809

Metzger, T., Irawan, A., Tsotsas, E.: Discrete modeling of drying kinetics of porous media. Proc. 3rd Nordic Drying Conference, Karlstad, Sweden (2005)

Nowicki S.C., Davis H.T., Scriven L.E. (1992). Microscopic determination of transport parameters in drying porous media. Dry. Technol. 10:925–946

Peglow, M.: Beitrag zur Modellbildung eigenschaftsverteilter Feststoffsysteme am Beispiel der Wirbelschicht-Sprühagglomeration. Dissertation, Universität Magdeburg (2005)

Peglow M., Kumar J., Warnecke G., Heinrich S., Mörl L., Hounslow M.J. (2006a). Improved discretized tracer mass distribution of Hounslow et al. AIChE J. 52:1326–1332

Peglow M., Kumar J., Warnecke G., Heinrich S., Mörl L. (2006b). A new technique to determine rate constants for growth and agglomeration with size- and time-dependent nuclei formation. Chem. Eng. Sci. 61:282–292

Perré P., Turner I.W. (1999). A 3-D version of TransPore: a comprehensive heat and mass transfer computational model for simulation the drying of porous media. Int. J. Heat Mass Transfer 42:4501–4521

Plourde F., Prat M. (2003). Pore network simulations of drying of capillary porous media. Influence of thermal gradients, Int. J. Heat Mass Transfer 46:1293–1307

Saage, G., Kwapinska, M., Tsotsas, E.: Discrete element simulation of the mixing time of granular solids. In: Proc. 16th International Symposium on Trends in Applications of Mathematics to Mechanics (pp. 441–450). Shaker Verlag (2005)

Schlünder E.U. (1980). Der Wärmeübergang an ruhende, bewegte und durchwirbelte Schüttschichten. VT-Verfahrenstechnik 14:459–468

Schlünder E.U. (1983). Heat transfer to packed and stirred beds from the surface of immersed bodies. Chem. Eng. Process. 18:31–53

Schlünder E.U., Mollekopf N. (1984). Vacuum contact drying of free flowing, mechanically agitated particulate material. Chem. Eng. Process. 18:93–111

Segura L.A., Toledo P.G. (2005). Pore-level modeling of isothermal drying of pore networks. Effects of gravity and pore shape and size distributions. Chem. Eng. J. 111:237–252

van Puyvelde D.R., Young B.R., Wilson M.A., Schmidt S.J. (1999). Experimental determination of transverse mixing kinetics in a rolling drum by image analysis. Powder Technol. 106:183–191

van Puyvelde D.R., Young B.R., Wilson M.A., Schmidt S.J. (2000). Modelling transverse mixing kinetics in a rolling drum. CJChE 78:635–642

Wunschmann, J.: Wärmeübertragung von beheizten Flächen an bewegte Schüttungen bei Normaldruck und Vakuum. Dissertation, Universität Karlsruhe (1974)

Yiotis A.G., Stubos A.K., Boudouvis A.G., Yortsos Y.C. (2001). A 2-D pore network model of the drying of single-component liquids in porous media. Adv. Water Resour. 24:439–460

Yiotis A.G., Stubos A.K., Boudouvis A.G., Tsimpanogiannis I.N., Yortsos Y.C. (2005). Pore-network modeling of isothermal drying in porous media. Trans. Porous Media 58:63–86

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Metzger, T., Kwapinska, M., Peglow, M. et al. Modern Modelling Methods in Drying. Transp Porous Med 66, 103–120 (2007). https://doi.org/10.1007/s11242-006-9025-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11242-006-9025-z