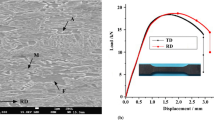

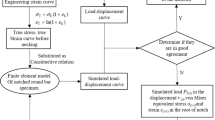

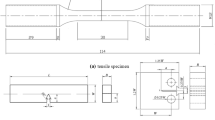

This work studied the ductile-brittle transition process of 15MnTi steel under different dynamic loading conditions. The strength of 15MnTi steel increased with strain rate because dislocation movement and element diffusion were inhibited. The fracture mode was different under different loading speeds. When the loading speed was lower than 0.025 m/s, the fracture mode was complete ductile fracture; when the loading speed was 0.1 –0.4 m/s, the fracture mode was ductile-brittle fracture; and when the loading speed was higher than 0.5 m/s, the fracture mode was a brittle fracture. In the three-point bending test, the dynamic brittle fracture rate of 15MnTi steel decreased with increasing crack tip constraint, and the brittle fracture resistance decreased with increasing loading rate. In the Charpy impact test, the fracture mode of the prefabricated crack specimens was a ductile fracture. In addition, when the loading rate was 0.1 m/s, the toughness characteristics were not obvious. The fracture had tear dimples at loading rates ranging from 1 to 3.5 m/s, showing certain ductile fracture characteristics. There were many dislocations in the matrix, and TiC was distributed in the matrix. Plenty of dislocations accumulated around the particles, which improved the strength by hindering the movement of the dislocations.

Similar content being viewed by others

References

Y. Li, D. Yao, H. Qiao, et al., “Dynamic ductile-brittle transition and fracture toughness measurement of metal under intermediate-low loading velocities,” Acta Mech Sin, 53, No. 2, 424–436 (2021). https://doi.org/10.6052/0459-1879-20-304

S. Paul, S. Bhattacharjee, S. K. Acharyya, and P. Sahoo, “Finite element simulation of fracture toughness testing of 20MnMoNi55 steel and the effect of loading rate on reference temperature,” P I Mech Eng L-J Mat, 235, No. 1, 162–175 (2020). https://doi.org/10.1177/1464420720956673

R. Chaouadi and J. L. Puzzolante, “Loading rate effect on ductile crack resistance of steels using precracked Charpy specimens,” Int J Pres Ves Pip, 85, No. 11, 752–761 (2008). https://doi.org/10.1016/j.ijpvp.2008.08.004

Q. Tong and S. Li, “A concurrent multiscale study of dynamic fracture,” Comput Meth Appl M, 366, 113075 (2020). https://doi.org/10.1016/j.cma.2020.113075

Z. J. Xu, Y. L. Li, and M. Kikuchi, “Research on Mode I and Mode II dynamic fracture in high strength steels under high loading rates,” Adv Mater Res, 33-37, 351–356 (2008). https://doi.org/10.4028/www.scientific.net/AMR.33-37.351

H. Chen, C. Zhang, H. Chen, et al., “Understanding microstructure-evolution-dependent fracture behaviors in pearlitic steels,” J Iron Steel Res Int, 27, No. 3, 334–341 (2020). https://doi.org/10.1007/s42243-019-00324-9

Q. L. Niu, W. W. Ming, M. Chen, et al., “Dynamic mechanical behavior of ultra high strength steel 30CrMnSiNi2A at high strain rates and elevated temperatures,” J Iron Steel Res Int, 24, No. 7, 724–729 (2017). https://doi.org/10.1016/S1006-706X(17)30109-7

C. H. Guo, F. C. Jiang, R. T. Liu, and Y. Yang, “Effect on the contact between fracture specimen and supports in Hopkinson bar loaded fracture test,” Int J Fracture, 169, No. 1, 77–84 (2011). http://dx.doi.org/https://doi.org/10.1007/s10704-011-9588-8

F. Dai, R. Chen, and K. Xia, “A semi-circular bend technique for determining dynamic fracture toughness,” Exp Mech, 50, No. 6, 783–791 (2010). http://dx.doi.org/https://doi.org/10.1007/s11340-009-9273-2

Z. Xu, Y. Li, and F. Huang, “Application of split Hopkinson tension bar technique to the study of dynamic fracture properties of materials,” Acta Mech Sin, 28, No. 2, 424–431 (2012). http://dx.doi.org/https://doi.org/10.1007/s10409-012-0046-2

D. Z. Li, Y. H. Wei, C.Y. Liu, et al., “Effects of high strain rate on properties and microstructure evolution of twip steel subjected to impact loading,” J Iron Steel Res Int, 17, No. 6, 67–73 (2010). http://doi.org/https://doi.org/10.1016/S1006-706X (10)60116-1

I. V. Varfolomeev and J. R. Klepaczko, “Effect of strain rate on the geometry of the plastic zone near a Mode II crack tip. Parametric analysis,” Strength Mater, 27, No. 3, 138–145 (1995). https://doi.org/10.1007/BF02209479

J. F. Kalthoff, “Fracture behavior under high rates of loading,” Eng Fract Mech, 23, No. 1, 289–298 (1986). https://doi.org/10.1016/0013-7944(86)90193-1

M. L. Wilson, R. H. Hawley, and J. Duffy, “The effect of loading rate and temperature on fracture initiation in 1020 hot-rolled steel,” Eng Fract Mech, 13, No. 2, 371–385 (1980). https://doi.org/10.1016/0013-7944(80)90066-1

S. Henschel and L. Kruger, “Effect of inhomogeneous distribution of non-metallic inclusions on crack path deflection in G42CrMo4 steel at different loading rates,” Int J Fracture, 9, No. 34, 326–333 (2015). https://doi.org/10.3221/IGF-ESIS.34.35

R. G. Davies and C. L. Magee, “The effect of strain-rate upon the tensile deformation of materials,” J Eng Mater Tech, 97, No. 2, 151–155 (1975). https://doi.org/10.1115/1.3443275

J. Y. Zhang, P. Jiang, Z. L. Zhu, et al., “Tensile properties and strain hardening mechanism of Cr-Mn-Si-Ni alloyed ultra-strength steel at different temperatures and strain rates,” J Alloy Compd, 842, No. 25, 155856 (2020). https://doi.org/10.1016/j.jallcom.2020.155856

F. Chen, Z. Cui, and S. Chen, “Recrystallization of 30Cr2Ni4MoV ultra-super-critical rotor steel during hot deformation. Part I: Dynamic recrystallization,” Mater Sci Eng A, 528, No. 15, 5073–5080 (2011). https://doi.org/10.1016/j.msea.2011.03.008

M. Itabashi and K. Kawata, “Carbon content effect on high-strain-rate tensile properties for carbon steels,” Int J Impact Eng, 24, No. 2, 117–131 (2000). https://doi.org/10.1016/S0734-743X(99)00050-0

S. Lee, S. Kim, B. Hwang, et al., “Effect of carbide distribution on the fracture toughness in the transition temperature region of an SA 508 steel,” Acta Mater, 50, No. 19, 4755–4762 (2002). https://doi.org/10.1016/S1359-6454(02)00313-0

H. Kim, M. Kang, H. J. Jung, et al., “Mechanisms of toughness improvement in Charpy impact and fracture toughness tests of non-heat-treating cold-drawn steel bar,” Mater Sci Eng A, 571, No. 1, 38–48 (2013). https://doi.org/10.1016/j.msea.2013.02.011

A. Inoue, T. Ogura, and T. Masumoto, “Burgers vectors of dislocations in cementite crystal,” Scripta Metall, 11, No. 1, 1-5 (1977). https://doi.org/10.1016/0036-9748(77)90002-3

Z. Zhang and D. L. Chen, “Consideration of Orowan strengthening effect in particulate-reinforced metal matrix nanocomposites: A model for predicting their yield strength,” Scripta Mater, 54, No. 7, 1321–1326 (2006). https://doi.org/10.1016/j.scriptamat.2005.12.017

W. T. Yu, J. Li, C. B. Shi, and Q. T. Zhu, “Effect of titanium on the microstructure and mechanical properties of high-carbon martensitic stainless steel 8Cr13MoV,” Metals, 6, No. 8, 193–208 (2016). https://doi.org/10.3390/met6080193

R. P. Todorov and K. G. Khristov, “Widmanstatten structure of carbon steels,” Met Sci Heat Treat, 46, Nos. 1–2, 49–53 (2004). https://doi.org/10.1023/B:MSAT.0000029601.58461.bd

Acknowledgment

This study was supported by the CNNC Science Fund for Talented Young Scholars, China (Contract No. K301007019001).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Problemy Mitsnosti, No. 3, p. 128, May – June, 2023

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, Y.L., Yao, D., Liu, Z.W. et al. The Ductile-Brittle Transition Mechanism of 15MnTi Steel Under Dynamic Loading. Strength Mater 55, 653–671 (2023). https://doi.org/10.1007/s11223-023-00556-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11223-023-00556-x