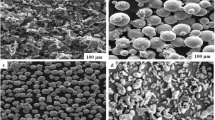

The article investigates the structure, mechanical and electrical properties of spark plasma sintered metal-based Ti-Al-C system composite materials. The initial powder consisting of 85% titanium and 15% aluminum was treated in kerosene by high voltage electrical discharge. Such a powder treatment allowed the formation of carbides and MAX-phases that strengthened sintered composites by spark plasma sintering. The microstructure of Ti-Al-C samples was examined by optical and electron scanning microscopy. Vickers hardness measurement revealed high microhardness – approximately 500–550 HV and more, depending on the sintering temperature of the samples. X-ray diffraction was used to determine the phase composition of samples. The electrical properties of the Ti-Al-C composites were evaluated by measuring their resistivity.

Similar content being viewed by others

References

M. D. Hayat, H. Singh, Z. He, and P. Cao, “Titanium metal matrix composites: An overview,” Compos Part A-Appl S, 121, 418–438 (2019).

O. N. Sizonenko, A. I. Ivliev, and G. B. Bagljuk, Promising Processes for the Manufacture of Powder Materials [in Russian], NUK, Nikolaev (2014).

V. V. Skorokhod, Yu. M. Solonin, and I. V. Uvarova, Chemical, Diffusion and Rheological Processes in the Technology of Powder Materials [in Russian], Naukova Dumka, Kiev (1990).

S. Szczepanik, Przeróbka Plastyczna Materiałów Spiekanych z Proszków i Kompozytów, UWN-D, Kraków (2003).

G. A. Gulyi, Scientific Foundations of Discharge-Pulse Technologies [in Russian], Naukova Dumka, Kiev (1990).

A. V. Ragulya and V. V. Skorokhod, Consolidated Nanostructured Materials [in Russian], Naukova Dumka, Kiev (2007).

E. G. Grigoriev and B. A. Kalin, Electropulse Technology for the Formation of Materials from Powders [in Russian], MIFI, Moscow (2008).

O. Sizonenko, S. Prokhorenko, A. Torpakov, et al., “The metal matrix composites reinforced by the fullerenes,” AIP Adv, 8, 085317 (2018). https://doi.org/10.1063/1.5031195

M. Parker, A. Pokatilov, K. Raba, and T. Kübarsepp, “Accurate measurements of electrical conductivity of metals in the range from 2 MS/m to 14 MS/m,” in: Proc. of 8th Int. DAAM Baltic Conf. “Industrial Engineering” (April 19–21, 2012, Tallinn, Estonia), pp. 700–704.

G. Bohm and G. Zech, Introduction to Statistics and Data Analysis for Physicists (2010). https://doi.org/10.3204/DESY-BOOK/statistics

O. Syzonenko, M. Prystash, A. Zaichenko, et al., “The impact of frequency composition of consolidation current on the structure and physical-mechanical properties of Ti-Al-C system metal matrix composites,” Materials Science. Non-Equilibrium Phase Transformations, 5, No. 4, 109–111 (2019).

C. Yang, F. Wang, T. Ai, and J. Zhu, “Microstructure and mechanical properties of in situ TiAl/Ti2AlC composites prepared by reactive hot pressing,” Ceram Int, 40, No. 6, 8165–8171 (2014).

S. C. Vogel1, D. Bhattacharyya, G. B. Viswanathan, et al., “Phase transformation textures in Ti-6Al-4V alloy,” Mater Sci Forum, 495–497, 681–686 (2005).

T. A. Prikhna, O. P. Ostash, A. S. Kuprin, et al., “A new MAX phases-based electroconductive coating for high-temperature oxidizing environment,” Compos Struct, 277, 114649 (2021).

W. Zhou, K. Li, J. Zhu, and R. Li, “In situ synthesis, mechanical and cyclic oxidation properties of Ti3AlC2/Al2O3 composites,” Adv Appl Ceram, 117, No. 6, 340–346 (2018).

M. C. Lee and G. Simkovich, “Electrical conduction behavior of cementite, Fe3C,” Metall Trans A, 18, 485–486 (1987). https://doi.org/10.1007/BF02648811

Acknowledgments

The presented work was performed with partial financial support from the Research Council of Lithuania and the Ministry of Education and Science of Ukraine in the framework of the "Application of High-Concentrated Energy Flows for Producing Nanostructured Polyfunctional Composite Materials” joint project according to the results of joint Ukrainian-Lithuanian R&D projects for the period of 2022–2023 contest (Reg. No. P-LUP-22-5).

In addition, the authors would like to express their gratitude to the Armed Forces of Ukraine for their bravery, which made this work possible even in the dark times of war.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Problemy Mitsnosti, No. 3, p. 121, May – June, 2023.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kandrotaitė-Janutienė, R., Mažeika, D. & Sizonenko, O. Investigation of a Structure and Mechanical and Electrical Properties of Ti-Al-C System Composites. Strength Mater 55, 566–574 (2023). https://doi.org/10.1007/s11223-023-00549-w

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11223-023-00549-w