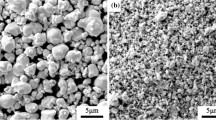

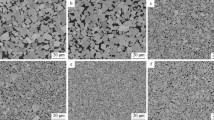

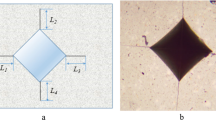

This paper reports the synthesis and properties of WC-Co-Ti(C0.5, N0.5)-Mo cemented carbides with various compositions by employing powder metallurgy processing technology. The effect of adding Mo to cemented carbides on their microstructure and mechanical properties is investigated. The volume shrinkage, porosity, microstructure characteristics, hardness, and indentation toughness are examined by analytical balance, indentation method, scanning electron microscope, and X-ray diffractometer, respectively. By adding 0.5 weight percent Mo to cemented carbides, the density and hardness can be increased to 14.12 g/cm3 and 1804.56 kgf/mm2, respectively, while the indentation fracture toughness remains at a tolerable level of approximately 7.6 MPa·m1/2. Furthermore, the addition of Mo to the WC-Co-Ti(C0.5, N0.5) cemented carbides can effectively inhibit Co loss, reduce microdefects in the systems, and improve the microstructure.

Similar content being viewed by others

References

H. Exner, “Physical and chemical nature of cemented carbides”, Int. Mater. Rev., 24, No. 1, 149–173 (1979).

B. Roebuck and E. Almond, “Deformation and fracture processes and the physical metallurgy of WC–Co hardmetals”, Int. Mater. Rev., 33, No. 1, 90–112 (1988).

Y. Peng, H. Miao, and Z. Peng, “Development of TiCN-based cermets: mechanical properties and wear mechanism”, Int. J. Refract. Met. H., 39, 78–89 (2013).

U. Rolander, G. Weinl, P. Lindahl, and H.-O. Andren, Titanium-Based Carbonitride Alloy with Controllable Wear Resistance and Toughness, EP0812367B1, European Patent Office (2002).

X. Cao, J. F. Jin, J. Y. Cao, et al., “Wear resistance of iron matrix composites reinforced by mixed-type particles”, J. Mater. Eng., 45, No. 8, 62–67 (2017).

Q. Z. Wang, Y. Liu, D. H. Guan, et al., “Effect of tin content on microstructures and mechanical properties of Ti(C, N)/NiCr cermets”, Acta Metall. Sin., 41, No. 11, 1121–1126 (2005).

D. S. Bai, J. F. Sun, W. Y. Chen, et al., “Molecular dynamics simulation of the diffusion behaviour between Co and Ti and its effect on the wear of WC/Co tools when titanium alloy is machined”, Ceram. Int., 42, No. 15, 17754–17763 (2016).

N. Li, X. F. Li, W. B. Zhang, et al., “Relation between the nitrogen gas pressure and structure characteristics of WC–Ti(C, N)–Co graded cemented carbides”, J. Alloy. Compd., 831, 154764 (2020).

O. Eso, Z. Z. Fang, and A. Griffo, “Kinetics of cobalt gradient formation during the liquid phase sintering of functionally graded WC–Co”, Int. J. Refract. Met. H., 25, No. 4, 286–292 (2007).

W. Zhang, Y. Liu, and Y. He, “Study on the cutting property of the coated cemented carbide tips with gradient structure”, Rare Metals and Cemented Carbides, 34, No. 3, 12–14 (2006).

D. Mari, S. Bolognini, T. Viatte, et al., “Study of the mechanical properties of TiCN–Wc–Co hardmetals by the interpretation of internal friction spectra”, Int. J. Refract. Met. H., 19, Nos. 4–6, 257–265 (2001).

J. Glühmann, M. Schneewei_, H. van den Berg, et al., “Functionally graded WC–Ti(C, N)–(Ta, Nb)C–Co hardmetals: metallurgy and performance”, Int. J. Refract. Met. H., 36, 38–45 (2013).

K. Choi, N. M. Hwang, and D.-Y. Kim, “Effect of VC addition on microstructural evolution of WC–Co alloy: mechanism of grain growth inhibition”, Powder Metall., 43, No. 2, 168–172 (2000).

W. Zhang, Y. Du, and Y. Peng, “Effect of TaC and NbC addition on the microstructure and hardness in graded cemented carbides: simulations and experiments”, Ceram. Int., 42, No. 1, 428–435 (2016).

Z. Zhao, J. W. Liu, H. G. Tang, et al., “Effect of Mo addition on the microstructure and properties of WC–Ni–Fe hard alloys”, J. Alloy. Compd., 646, 155–160 (2015).

H. S. Lian, M. F. Gong, M. S. Li, et al., “Influence of Mo content on microstructure and properties of WC-Co-Ti(C, N)-Ni-Mo cemented carbides”, Mater. Mech. Eng., 42, No. 11, 37–41 (2018).

G. R. Anstis, P. Chantikul, B. R. Lawn, et al., “A critical evaluation of indentation techniques for measuring fracture toughness: I, Direct crack measurements”, J. Am. Ceram. Soc., 64, No. 9, 533–538 (1981).

D. Sivaprahasam, S. B. Chandrasekar, and R. Sundaresan, “Microstructure and mechanical properties of nanocrystalline WC–12Co consolidated by spark plasma sintering”, Int. J. Refract. Met. H., 25, No. 2, 144–152 (2007).

J. Garcia, S. Englund, and F. Haglof, “Controlling cobalt capping in sintering process of cermets”, Int. J. Refract. Met. H., 62, 126–133 (2017).

H. J. Zhou, C. Z. Huang, B. Zou, et al., “Effects of sintering processes on the mechanical properties and microstructure of Ti(C, N)-based cermet cutting tool materials”, Int. J. Refract. Met. H., 47, 71–79 (2014).

Z. Lei, Y. Dong, and Y. Yang, “Influence of heat treatment on fracture mechanism of WC-Co cemented carbide”, Ordnance Mater. Sci. Eng., 03, 18–23 (1991).

X. R. Zhao, D. Zou, M. X. Zhang, et al., “Effect of sintering temperature on the microstructure and properties of ultra-fine Ti(C, N)-based cermets”, Mater. Trans., 57, 1615–1619 (2016).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Problemy Mitsnosti, No. 3, p. 113, May – June, 2022.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sui, G.Z., Gong, M.F., Wang, X.H. et al. Microstructure and Mechanical Properties of WC-Co-Ti(C0.5, N0.5)-Mo Cemented Carbides. Strength Mater 54, 473–482 (2022). https://doi.org/10.1007/s11223-022-00422-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11223-022-00422-2