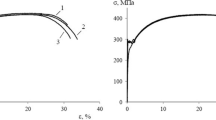

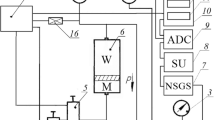

Deformation of rectilinear elements of Du 200 pipeline made of 20 steel under cyclic loading with internal pressure has been studied experimentally. Tests were carried out on a pneumohydraulic bench under conditions close to plane stress state, room temperature, and cycle asymmetry under soft loading mode (stress control). Circumferential and axial strains were recorded at three points of a diametrical section located in the middle of the element under study. Two tubular elements were tested at different values of maximum and amplitude stresses based on 100 cycles of loading. Deformation curves (cyclic creep) of tubes in a circular direction have been obtained, the character of which is significantly non-uniform in comparison with deformation of laboratory specimens. It is shown that even a slight increase in maximum (by 4%) and amplitude (by 8%) stresses significantly (up to 50%) increases the cyclic creep strains in the circular direction. Such growth of deformations can be explained by a peculiarity of 20 steel, the deformation diagram of which in the elastoplastic transition area contains a yield point, which determines intensive deformation of the material. Fixed plastic deformations in the axial direction are more than an order smaller than circular ones, and with increasing loading cycles, they change insignificantly and coincide for the two studied tubular elements.

Similar content being viewed by others

References

SNiP 2.05.06-85. Main Pipelines. Construction Norms and Rules [in Russian], TsITP Gosstroi of the USSR, Moscow (1985).

L. Bairstow, “The elastic limits of iron and steel under cyclic variations of stresses”, Phil. Trans. Roy. Soc. London A, 210, 35–55 (1911).

V. A. Strizhalo, Cyclic Strength and Creep of Metals under Low-Cycle Loading at Low and High Temperatures [in Russian], Naukova Dumka, Kiev (1978).

T. Hassan and S. Kyriakides, “Ratcheting in cyclic plasticity, part I: Uniaxial behavior”, Int. J. Plasticity, 8, No. 1, 91–116 (1992).

A. Haupt and B. Schinke, “Experimental on the ratchetting behavior of AISI 316L(N) austenitic steel at room temperature”, J. Eng. Mater. T.-ASME, 118, No. 3, 281–284 (1996).

Y. Jiang, “Benchmark experiments and characteristic cyclic plasticity deformation”, Int. J. Plasticity, 24, No. 9, 1481–1515 (2008).

S. K. Paul, “A critical review of experimental aspects in ratcheting fatigue: microstructure to specimen to component”, J. Mater. Res. Technol., 8, No. 5, 4894–4914 (2019).

M. V. Borodii, “Modeling of the asymmetric low-cycle loading in the space of stresses”, Strength Mater., 30, No. 5, 472–480 (1998), https://doi.org/10.1007/BF02522629.

M. Dahlberg and P. Segle, Evaluation of Models for Cyclic Plastic Deformation. A Literature Study, Report No. 2010:45, Swedish Radiation Safety Authority (2010).

H. Li, M. Wen, G. Chen, et al., “Constitutive modeling for the anisotropic uniaxial ratcheting behavior of Zircaloy-4 alloy at room temperature”, J. Nucl. Mater., 443, Nos. 1–3, 152–160 (2013).

M. V. Borodii, V. O. Stryzhalo, M. K. Kucher, et al., “An experimental study of ratcheting effect under multiaxial proportional loading”, Strength Mater., 46, No. 1, 97–104 (2014), https://doi.org/10.1007/s11223-014-9520-3.

T. Hassan, E. Corona, and S. Kyriakides, “Ratcheting in cyclic plasticity, part 2: Multiaxial behavior”, Int. J. Plasticity, 8, No. 2, 117–146 (1992).

T. Hassan, L. Taleb, and S. Krishna, “Influences of non-proportional loading paths on ratcheting responses and simulations by two recent cyclic plasticity models”, Int. J. Plasticity, 24, No. 10, 1863–1889 (2008).

G. Kang, Q. Gao, L. Cai, and Y. Sun, “Experimental study on uniaxial and nonproportionally multiaxial ratcheting of SS304 stainless steel at room and high temperatures”, Nucl. Eng. Des., 216, Nos. 1–3, 13–26 (2002).

K. S. Kim, R. Jiao, X. Chen, and M. Sakane, “Ratcheting of stainless steel 304 under multiaxial nonproportional loading”, J. Press. Vess. T.-ASME, 131, No. 2, 021405 (2009).

M. P. Adamchuk and M. V. Borodii, “Determination of steady ratcheting strain rate under biaxial loading based on cycle nonproportionality coefficient”, Strength Mater., 49, No. 2, 250–255 (2017), https://doi.org/10.1007/s11223-017-9864-6.

S. M. Hamidinejad, Development of a Kinematic Hardening Rule to Assess Ratcheting Response of Materials under Multiaxial Loading Spectra, PhD Thesis of Mechanical Engineering, Ryerson University, Toronto, Ontario (2015).

M. V. Borodii, M. P. Adamchuk, and V. O. Stryzhalo, “Specification of the parameters of an exponential heredity kernel of the endochronic theory in describing ratcheting under biaxial loading”, Strength Mater., 50, No. 4, 644–654 (2018), https://doi.org/10.1007/s11223-018-0009-3.

T. Hassan and S. M. Rahman, “Simulation of ratcheting responses of elbow piping components”, in: ASME 2009 Pressure Vessels and Piping Conference (July, 26–30, 2009, Prague, Czech Republic), Vol. 1, Paper No. PVP2009-77819 (2009), pp. 103–108.

S. Vishnuvardhan, G. Raghava, P. Gandhi, et al., “Ratcheting failure of pressurised straight pipes and elbows under reversed bending”, Int. J. Pres. Ves. Pip., 105–106, 79–89 (2013).

GOST 1050-88. Long Products, Calibrated, with Special Surface Finish of Carbon Quality Structural Steel. General Specifications [in Russian], Introduced on January 1, 1991.

DSTU ISO 6892-1:2019 (ISO 6892-1:2016, IDT). Metallic Materials. Tensile Tests. Part 1. Test Method at Room Temperature [in Ukrainian], Valid from July 1, 2020.

V. Stryzhalo, M. Zarazovskii, A. Bohdan, et al., “Estimation of the load carrying capacity of the bellows compensator for gas pipelines in the areas of mining production”, in: ASME2020 Pressure Vessels & Piping Conference (August, 3, 2020, Virtual, Online), Vol. 3, Paper No. PVP2020-21738, V003T03A019 (2020), https://doi.org/10.1115/PVP2020-21738.

DNAOP 0.00-1.07-94. Rules of Construction and Safe Operation of Pressure Vessels [in Ukrainian], State Supervision of Labor Protection of Ukraine, Kyiv (1998).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Problemy Mitsnosti, No. 3, pp. 39 – 48, May – June, 2022.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Borodii, M.V., Adamchuk, M.P., Stryzhalo, V.O. et al. Experimental Study on Cyclic Creep of Pipes. Strength Mater 54, 378–386 (2022). https://doi.org/10.1007/s11223-022-00413-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11223-022-00413-3