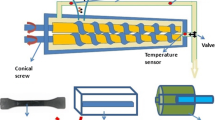

The development and large-scale implementation of multifunctional advanced materials with smart and intelligent properties like shape memory are very topical. In the present work, we report the development of multifunctional graphene nanoplatelets (GNPs)-reinforced thermo-responsive shape memory composites, in ether type shape memory polyurethane (SMPU) matrix. A unique twin screw co-rotating microcompounder with a back flow channel was operated to ensure proper dispersion of GNPs in the SMPU matrix for developing different compositions of nanocomposites, namely SMC0, SMC1, SMC2, and SMC3, respectively. The detailed characterizations and properties of the above developed nanocomposites were studied using various complementary techniques for spectroscopy, morphology, mechanical, thermal, shape memory, DMA, etc. The dynamic thermomechanical properties of all the developed nanocomposites were studied at 0.1 and 10 Hz, respectively. Structure of SMP and developed composite were also analyzed using various spectroscopic methods. The addition of GNPs to the SMP matrix improved the mechanical and shape memory properties, although a noticeable impact on thermal property is also reported. The fractured microphotographs reveal the uniform dispersion of GNP in SMPU. Addition of 1 phr GNPs increased storage modulus of SMPU from 3.14 to 4.11 GPa and the value of tan δ peak was decreased from 0.81 to 0.53, respectively. The GNPs in SMPU matrix influences the shape recovery, which is improved with the addition of GNPs in the experimental range.

Similar content being viewed by others

Change history

10 March 2021

A Correction to this paper has been published: https://doi.org/10.1007/s11223-021-00254-6

References

S. A. R. Hashmi, H. C. Prasad, R. Abishera, et al., “Improved recovery stress in multi-walled-carbonnanotubes reinforced polyurethane,” Mater. Design, 67, 492–500 (2015).

Y. Wu, J. Hu, C. Zhang, et al., “A facile approach to fabricate a UV/heat dual-responsive triple shape memory polymer,” J. Mater. Chem. A, 3, No. 1, 97–100 (2015).

E. Pieczyska, M. Staszczak, M. Maj, et al., “Investigation of thermal effects accompanying tensile deformation of Shape Memory Polymer PU-SMP,” Meas. Automat. Monitor., 61, No. 6, 203–205 (2015).

C. D. Eisenbach, “Isomerization of aromatic azo chromophores in poly(ethyl acrylate) networks and photomechanical effect,” Polymer, 21, No. 10, 1175–1179 (1980).

H. Finkelmann, E. Nishikawa, G. Pereira, and M. Warner, “A new opto-mechanical effect in solids,” Phys. Rev. Lett., 87, No. 1, 015501 (2001).

B. Yang, W. Huang, C. Li, and L. Li, “Effects of moisture on the thermomechanical properties of a polyurethane shape memory polymer,” Polymer, 47, No. 4, 1348–1356 (2006).

W. Wang, D. Liu, Y. Liu, et al., “Electrical actuation properties of reduced graphene oxide paper/epoxy-based shape memory composites,” Compos. Sci. Technol., 106, 20–24 (2015).

X. Liu, H. Li, Q. Zeng, et al., “Electro-active shape memory composites enhanced by flexible carbon nanotube/graphene aerogels,” J. Mater. Chem. A, 3, No. 21, 11641–11649 (2015).

A. M. Schmidt, “Electromagnetic activation of shape memory polymer networks containing magnetic nanoparticles,” Macromol. Rapid Comm., 27, No. 14, 1168–1172 (2006).

X. J. Han, Z. Q. Dong, M. M. Fan, et al., “pH-induced shape-memory polymers,” Macromol. Rapid Comm., 33, No. 12, 1055–1060 (2012).

C. Liu, H. Qin, and P. Mather, “Review of progress in shape-memory polymers,” J. Mater. Chem., 17, No. 16, 1543–1558 (2007).

J. Hu, Y. Zhu, H. Huang, and J. Lu, “Recent advances in shape–memory polymers: Structure, mechanism, functionality, modeling and applications,” Prog. Polym. Sci., 37, No. 12, 1720–1763 (2012).

I. A. Rousseau, “Challenges of shape memory polymers: A review of the progress toward overcoming SMP’s limitations,” Polym. Eng. Sci., 48, No. 11, 2075–2089 (2008).

B. K. Kim, S. Y. Lee, and M. Xu, “Polyurethanes having shape memory effects,” Polymer, 37, No. 26, 5781–5793 (1996).

Q. Meng, J. Hu, and Y. Zhu, “Properties of shape memory polyurethane used as a low-temperature thermoplastic biomedical orthotic material: influence of hard segment content,” J. Biomater. Sci. Polym. Ed., 19, No. 11, 1437–1454 (2008).

N. Yoshihara, H. Ishihara, and T. Yamada, “Relationship between segment structures and elastic properties of segmented poly(urethane-urea) elastic fibers,” Polym. Eng. Sci., 43, No. 11, 1740–1754 (2003).

Y. Liu, K. Gall, M. L. Dunn, and P. McCluskey, “Thermomechanics of shape memory polymer nanocomposites,” Mech. Mater., 36, No. 10, 929–940 (2004).

F. Cao and S. C. Jana, “Nanoclay-tethered shape memory polyurethane nanocomposites,” Polymer, 48, No. 13, 3790–3800 (2007).

A. G. R. Carlos, F. G. D. Mario, K. Hoejin, et al., “3D printing of shape memory polymer (SMP)/carbon black (CB) nanocomposites with electro-responsive toughness enhancement,” Mater. Res. Express, 5, No. 6, 065704 (2018).

F.-P. Du, E.-Z. Ye, W. Yang, et al., “Electroactive shape memory polymer based on optimized multi-walled carbon nanotubes/polyvinyl alcohol nanocomposites,” Compos. Part B-Eng., 68, 170–175 (2015).

A. S. Olalla, V. Sessini, E. G. Torres, and L. Peponi, Smart Nanocellulose Composites with Shape-Memory Behavior, in: D. Puglia, E. Fortunati, and J. M. Kenny (Eds.), Multifunctional Polymeric Nanocomposites Based on Cellulosic Reinforcements, Ch. 9, Elsevier Inc. (2016), pp. 277–312.

D. Yuan, D. Pedrazzoli, G. Pircheraghi, and I. Manas-Zloczower, “Melt compounding of thermoplastic polyurethanes incorporating 1D and 2D carbon nanofillers,” Polym.-Plast. Technol., 56, No. 7, 732–743 (2017).

A. Nieto, D. Lahiri, and A. Agarwal, “Synthesis and properties of bulk graphene nanoplatelets consolidated by spark plasma sintering,” Carbon, 50, No. 11, 4068– 4077 (2012).

S. Lashgari, M. Karrabi, I. Ghasemi, et al.,, “Shape memory nanocomposite of poly(L-lactic acid)/graphene nanoplatelets triggered by infrared light and thermal heating,” Express Polym. Lett., 10, No. 4, 349–359 (2016).

T. Williams, M. Meador, S. Miller, and D. Scheiman, “Effect of graphene addition on shape memory behavior of epoxy resins,” NASA Glenn Research Center, Polymers Branch, Structures and Materials Division (2011), https://ntrs.nasa.gov/search.jsp?R=20120000854.

H. C. Prasad, S. A. R. Hashmi, A. Naik, and H. N. Bhargaw, “Improved shape memory effects in multiwalled-carbon-nano-tube reinforced thermosetting polyurethane composites,” J. Appl. Polym. Sci., 134, No. 7, 44389 (2017), https://doi.org/10.1002/app.44389.

V. A. E. Barrios, J. R. R. Mendez, N. V. P. Aguilar, et al., FTIR – An Essential Characterization Technique for Polymeric Materials, in: T. Theophanides (Ed.), Infrared Spectroscopy: Materials Science, Engineering and Technology, InTech (2012), pp. 195–212.

A. S. Patole, S. P. Patole, H. Kang, et al., “A facile approach to the fabrication of graphene/polystyrene nanocomposite by in situ microemulsion polymerization,” J. Colloid Interf. Sci., 350, No. 2, 530–537 (2010).

I. M. Inuwa, A. Hassan, S. A. Samsudin, et al., “Mechanical and thermal properties of exfoliated graphite nanoplatelets reinforced polyethylene terephthalate/polypropylene composites,” Polym. Composite., 35, No. 10, 2029–2035 (2014).

N. Hameed, P. A. Sreekumar, B. Francis, et al., “Morphology, dynamic mechanical and thermal studies on poly(styrene-co-acrylonitrile) modified epoxy resin/glass fibre composites,” Compos. Part A-Appl. S., 38, No. 12, 2422–2432 (2007).

Acknowledgments

The first author is highly thankful to CSIR, New Delhi, for granting Fellowship under which the present work was carried out. Authors are grateful to Director CSIR-AMPRI Bhopal for providing necessary institutional facilities and encouragement.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Problemy Prochnosti, No. 5, pp. 130 – 143, September – October, 2019

Rights and permissions

About this article

Cite this article

Gupta, R.K., Hashmi, S.A.R., Verma, S. et al. Development of Graphene Nanoplatelets-Reinforced Thermo-Responsive Shape Memory Nanocomposites for High Recovery Force Applications. Strength Mater 51, 793–804 (2019). https://doi.org/10.1007/s11223-019-00130-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11223-019-00130-4