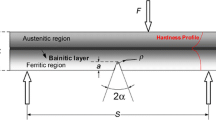

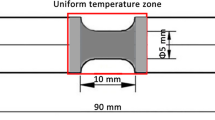

Functionally graded steels (FGS) are a group of functionally graded materials with elastic-plastic properties that are recently produced from austenitic stainless steel and carbon ferritic steel via electroslag remelting process. FGSs provide a possible solution to improve the properties of composites including martensitic and bainitic brittle phases. In the present work, keeping into account the relationship between the impact energy and the notch tip plastic zone size, an analytical model has been developed to predict the Charpy impact energy of bainitic and martensitic FGSs. The Charpy impact energy of the FGSs is compared with that of a specimen made of the homogeneous material corresponding to the layer that includes the notch tip. Moreover, three-dimensional finite element method (FEM) simulation of the process has been carried out via ABAQUS software. The material properties of the layers have been obtained considering the Holloman law for the plastic region. Meanwhile, an exponential variations of the material parameters along the specimen width have been considered. The results of the model show a sound agreement with previous results taken from the literature and the FEM results.

Similar content being viewed by others

References

R. Brighenti and A. Carpinteri, “Some considerations on failure of solids and liquids,” Strength Mater., 42, No. 2, 154–166 (2010).

D. K. Jha, T. Kant, and R. K. Singh, “A critical review of recent research on functionally graded plates,” Comp. Struct., 96, 833–849 (2013).

B. Chehab, H. Zurob, D. Embury, et al., “Compositionally graded steels: A strategy for materials development,” Adv. Eng. Mater., 11, No. 12, 992–999 (2009).

B. Skoczen, “Functionally graded structural members obtained via the low temperature strain induced phase transformation,” Int. J. Solids Struct., 44, 5182–5207 (2007).

J. Aghazadeh Mohandesi and M. H. Shahosseini, “Transformation characteristics of functionally graded steels produced by electroslag remelting,” Met. Mater. Trans. A, 36, 3471–3476 (2005).

J. Aghazadeh Mohandesi, M. H. Shahosseinie, and R. Parastar Namin, “Tensile behavior of functionally graded steels produced by electroslag remelting,” Metall. Mater. Trans. A, 37, 2125–2132 (2006).

A. Nazari, J. Aghazadeh Mohandesi, and S. Tavareh, “Microhardness profile prediction of a graded steel by strain gradient plasticity theory,” Comput. Mater. Sci., 50, 1781–1784 (2011).

A. Nazari, J. Aghazadeh Mohandesi and S. Tavareh, “Modeling tensile strength of austenitic graded steel based on the strain gradient plasticity theory,” Comput. Mater. Sci., 50, 1791–1794 (2011).

M. Abolghasemzadeh, H. Samareh Salavati Pour, F. Berto, and Y. Alizadeh, “Modeling of flow stress of bainitic and martensitic functionally graded steels under hot compression,” Mater. Sci. Eng. A, 534, 329–338 (2012).

E. Barati, Y. Alizadeh, and J. Aghazadeh Mohandesi, “J-integral evaluation of austenitic–martensitic functionally graded steel in plates weakened by U-notches,” Eng. Fract. Mech., 77, 3341–3358 (2010).

A. Nazari and J. Aghazadeh Mohandesi, “Impact energy of functionally graded steels with crack divider configuration,” J. Mater. Sci. Technol., 25, 847–852 (2009).

A. Nazari and J. Aghazadeh Mohandesi, “Modeling impact energy of functionally graded steels in crack divider configuration,” Mater. Sci. Technol., 26, 1377–1383 (2010).

A. Nazari, J. Aghazadeh Mohandesi, and S. Riahi, “Modeling impact energy of functionally graded steels in crack divider configuration using modified stress–strain curve data,” Int. J. Damage Mech., 21, 27–50 (2012).

A. Nazari and S. M. M. Najafi, “Prediction Charpy impact energy of bcc and fcc functionally graded steels in crack divider configuration by strain gradient plasticity theory,” Comput. Mater. Sci., 50, 3178–3183 (2011).

A. Nazari, “Application of strain gradient plasticity theory to model Charpy impact energy of functionally graded steels,” Comput. Mater. Sci., 50, 3410–3416 (2011).

A. Nazari, “Application of strain gradient plasticity theory to model Charpy impact energy of functionally graded steels using modified stress–strain curve data,” Comput. Mater. Sci., 51, 281–289 (2012).

A. Nazari and J. Aghazadeh Mohandesi, “Impact energy of functionally graded steels in crack arrester configuration,” J. Mater. Eng. Perform., 19, 1058–1064 (2010).

A. A. Baron, “A thermodynamic model for fracture toughness prediction,” Eng. Fract. Mech., 46, 245–251 (1993).

C. H. Gür and I. Yildiz, “Non-destructive investigation on the effect of precipitation hardening on impact toughness of 7020 Al-Zn-Mg alloy,” Mater. Sci. Eng. A, 382, 395–400 (2004).

R. W. Hertzberg, Deformation and Fracture Mechanics of Engineering Materials, 4th edition, John Wiley, New York (1996).

V. Leskovðek, B. Ule, and B. Liðèiã, “Relations between fracture toughness, hardness and microstructure of vacuum heat-treated high-speed steel,” J. Mater. Process. Technol., 127, 298–308 (2002).

G. C. Sih and D. Y. Tzou, “Dynamic fracture of Charpy V-notch specimen,” Theor. Appl. Fract. Mech., 5, 189–203 (1986).

M. R. Ayatollahi and A. R. Torabi, “Brittle fracture in rounded-tip V-shaped notches,” Mater. Des., 31, 60–67 (2010).

P. Lazzarin and R. Zambardi, “A finite-volume-energy based approach to predict the static and fatigue behavior of components with sharp V-shaped notches,” Int. J. Fract., 112, 275–298 (2001).

J. Aghazadeh Mohandesi, A. Nazari, M. H. Vishkasogheh, and M. Abedi, “Modeling fracture toughness of functionally graded steels in crack divider configuration,” Modell. Simul. Mater. Sci. Eng., 18, 1–13 (2010).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Problemy Prochnosti, No. 5, pp. 140 – 159, September – October, 2014.

Rights and permissions

About this article

Cite this article

Jam, J.E., Abolghasemzadeh, M., Salavati, H. et al. The Effect of Notch Tip Position on the Charpy Impact Energy for Bainitic and Martensitic Functionally Graded Steels. Strength Mater 46, 700–716 (2014). https://doi.org/10.1007/s11223-014-9604-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11223-014-9604-0