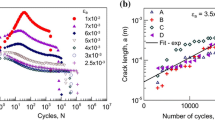

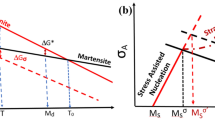

The characteristic changes of the cyclic plastic stress–strain response of stainless steel and superalloys derived from the analysis of hysteresis loop at different temperatures are reported. The evolution of the surface relief in strain controlled cycling is documented using high resolution SEM and TEM. The mechanisms leading to cyclic strain localization, formation of surface relief, fatigue crack initiation and early crack growth are discussed.

Similar content being viewed by others

References

R. Ohtani, “High-temperature fatigue,” in: I. Milne, R. O. Ritchie, and B. Karihaloo (Eds.), Comprehensive Structural Integrity, Vol. 4, Elsevier, Amsterdam (2003), pp. 327–344.

A. Pineau and S. D. Antolovich, “High temperature fatigue of nickel-base superalloys – a review with special emphasis on deformation modes and oxidation,” Eng. Failure Anal., 16, 2668–2697 (2009).

M. Petrenec, K. Obrtlík, and J. Polák, “Inhomogeneous dislocation structure in fatigued INCONEL 713LC superalloy at room and elevated temperatures,” Mater. Sci. Eng., A400-401, 485–488 (2005).

J. Polák, “Cyclic deformation, crack initiation, and low cycle fatigue,” in: I. Milne, R. O. Ritchie, and B. Karihaloo (Eds.), Comprehensive Structural Integrity, Vol. 4, Elsevier, Amsterdam, (2003), pp. 1–39.

J. Man, K. Obrtlík, and J. Polák, “Extrusions and intrusions in fatigued metals. Part 1. State of the art and history,” Phil. Mag., 89, 1295–1336 (2009).

J. Polák and M. Klesnil, “The hysteresis loop. 1. A statistical theory,” Fatigue Eng. Mater. Struct., 5, 19–32 (1982).

G. Masing, “Zur Heyn’schen Theorie der Verfestigung der Metalle durch verborgene elastische Spannungen,” Wiss. Ver. Siemens-Konzern, 3, 231–239 (1923).

N. N. Afanas’ev, Statistical Theory of Fatigue Strength of Metals [in Russian], AN UkrSSR, Kiev (1953).

J. Polák, M. Klesnil, and J. Helesic, “The hysteresis loop. 2. An analysis of the loop shape,” Fatigue Eng. Mater. Struct., 5, 33–44 (1982).

J. Polák, F. Fardoun, and S. Degallaix, “Analysis of the hysteresis loop in stainless steels. I. Austenitic and ferritic steels,” Mater. Sci. Eng., A297, 144–153 (2001).

J. Polák, F. Fardoun, and S. Degallaix, “Analysis of the hysteresis loop in stainless steels. II. Austeniticferritic duplex steel and the effect of nitrogen,” Mater. Sci. Eng., A297, 154–161 (2001).

M. Šmid, M. Petrenec, J. Polák, et al., “Analysis of effective and internal cyclic stress components in the Inconel superalloy fatigued at elevated temperature,” Adv. Mater. Res., 278, 393–398 (2011).

R. P. Wahi, J. Auerswald, D. Mukherji, et al., “Damage mechanisms of single and polycrystalline nickel base superalloys SC16 and IN738LC under high temperature LCF loading,” Int. J. Fatigue, 19, S89–S94 (1997).

K. Obrtlík, A. Chlupova, M. Petrenec, and J. Polák, “Low cycle fatigue of cast superalloy Inconel 738LC at high temperature,” Key Eng. Mater., 385-387, 581–584 (2008).

K. Obrtlík, M. Petrenec, J. Man, et al., “Isothermal fatigue behavior of cast superalloy Inconel 792-5A at 23 and 900°C,” J. Mater. Sci., 44, 3305–3314 (2009).

J. Polák, “On the role of point defects in fatigue crack initiation,” Mater. Sci. Eng., 92, 71–80 (1987).

Acknowledgment

The support of the present work by the grants Nos. 13-23652S and P204/11/1453 of the Grant Agency of the Czech Republic is acknowledged.

Author information

Authors and Affiliations

Additional information

Translated from Problemy Prochnosti, No. 5, pp. 27 – 34, September – October, 2014.

Rights and permissions

About this article

Cite this article

Polák, J., Obrtlík, K. & Petrenec, M. Cyclic Plastic Response and Damage in Materials for High Temperature Applications*. Strength Mater 46, 601–607 (2014). https://doi.org/10.1007/s11223-014-9588-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11223-014-9588-9