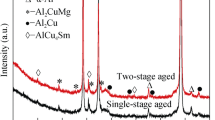

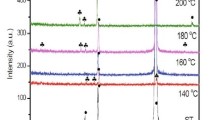

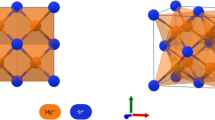

Microstructural features and mechanical properties of Al–Cu–Mg alloy (AA2024) were examined after aging the alloy between 105–195°C for various durations. One set of the specimens was aged at 105, 135, 165, and 195°C for 2 h, whereas the aging of other set of specimens at these temperatures was performed for 3.5, 3, 2.5, and 2 h, respectively. X-ray diffraction and scanning electron microscopy results indicated the formation of S- (Al2CuMg) and Θ- (Al2Cu) phase precipitates whose density and size changed with aging time and the temperatures. Anomalous variations in yield strength, ultimate tensile strength, plastic elongation, elastic modulus and hardness were observed with either changing the aging temperature, or the time. However, the specimens aged at 135 and 195°C for 2 h displayed the maximum strength and hardness along with a slight decrease in their plasticity as compared to those aged at other temperatures with various durations.

Similar content being viewed by others

References

A. Wilm, “Physikalisch-metallurgische Untersuchungen über magnesiumhaltige Aluminiumlegierungen,” Metallurgie, 8, 225–227 (1911).

A. Guinier, “Structure of age-hardened aluminium-copper alloys,” Nature, 142, 569–570 (1938).

G. D. Preston, “Structure of age-hardened aluminium-copper alloys,” Nature, 142, 570 (1938).

Y. A. Bagaryatsky, “Structural changes on aging Al–Cu–Mg alloys,” Dokl. AN SSSR, 87, 397–401 (1952).

J. M. Silcock, “The structural ageing characteristics of Al–Cu–Mg alloys with copper:magnesium weight ratios 7:1 and 2.2:1,” J. Inst. Met., 89, 203–210 (1960-61).

H. Perlitz and A. Westgren, “The crystal structure of AlCuMg,” Ark. Kemi. Mineral. Geol., 16B, 1–5 (1943).

L. F. Mondolfo, Aluminum Alloys: Structure and Properties, Butterworths, London (1976).

A. K. Gupta, P. Gaunt, and M. C. Chaturvedi, “The crystallography and morphology of the S′-phase precipitate in an Al(CuMg) alloy,” Phil. Mag. A, 55, 375–387 (1987).

S. P. Ringer, K. Hono, I. J. Polmear, and T. Sakurai, “Precipitation processes during the early stages of ageing in Al–Cu–Mg alloys,” Appl. Surf. Sci., 94/95, 253–260 (1996).

R. Kilaas and V. Radmilovic, “Structure determination and structure refinement of Al2CuMg precipitates by quantitative high-resolution electron microscopy,” Ultramicroscopy, 88, No. 1, 63–72 (2001).

C. Genevois, A. Deschamps, A. Denquin, and B. Doisneau-cottignies, “Quantitative investigation of precipitation and mechanical behaviour for AA2024 friction stir welds,” Acta Mater., 53, No. 8, 2447–2458 (2005).

S. Abis, M. Massazza, P. Mengucci, and G. Riontino, “Early ageing mechanisms in a high-copper AlCuMg alloy,” Scr. Mater., 45, No. 6, 685– 691 (2001).

H.-C. Shih, N. J. Ho, and J. C. Huang, “Kinetic study of precipitation behavior in Al–Cu–Mg and 2024 aluminum alloys,” Metall. Mater. Trans., 27A, 2479–2494 (1996).

S. C. Wang and M. J. Starink, “Review of precipitation in Al–Cu–Mg(Li) alloys,” Int. Mater. Rev., 50, 193–215 (2005).

V. Radmilovic, R. Kilaas, U. Dahmen, and G. J. Shiflet, “Structure and morphology of S-phase precipitates in aluminum,” Acta Mater., 47, 3987– 3997 (1999).

Z. Feng, Y. Yang, B. Huang, et al., “Precipitation process along dislocations in Al–Cu–Mg alloy during artificial aging,” Mater. Sci. Eng. A, 528, Issue 2, 706–714 (2010).

T. S. Parel, S. C. Wang, and M. J. Starink, “Hardening of an Al–Cu–Mg alloy containing type I and II S phase precipitates,” Mater. Des., 31, S2–S5 (2010).

N. Afify, A. Gaber, A. M. Abousehly, and Y. M. Abou Deif, “Precipitation kinetics in supersaturated Al–2.0 at% Cu–1.0 at% Mg alloy,” Mater. Trans., 51, No. 2, 317–320 (2010).

S. C. Wang, M. J. Starink, and N. Gao, “Precipitation hardening in Al–Cu– Mg alloys,” Scr. Mater., 54, 287–291 (2006).

S. C. Wang and M. J. Starink, “Two types of S phase precipitates in Al–Cu–Mg alloys,” Acta Mater., 55, No. 3, 933–941 (2007).

J. M. Palmerin, Héctor J. Dorantes Rosales, Victor M. López Hirata, et al., “Hardening behavior in aged Al–4%Cu–0.3%Mg alloys with 0.5 and 2%Ag additions,” Mater. Trans., 50, No. 12, 2785–2789 (2009).

S. N. Gurugubelli, “The effect of ageing on impact toughness and microstructure of 2024 Al–Cu–Mg alloy,” World Acad. Sci., Eng. Technol., 62, 648–650 (2012).

M. K. Abbass, “Effect of aging time on the mechanical properties of friction stir spot welding of Al-alloy (AA2024),” Int. J. Eng. Res. Appl., 2, 1366–1374 (2012).

D. A. P. Reis, A. A. Couto, N. I. Domingues, Jr., et al., “Effect of artificial aging on the mechanical properties of an aerospace aluminum alloy 2024,” Defect Diff. Forum, 326–328, 193–198 (2012).

J. F. Li, Z. Ziqiao, J. Na, and T. Chengyu, “Localized corrosion mechanism of 2xxx-series Al alloy containing S(Al2CuMg) and θ′(Al2Cu) precipitates in 4.0% NaCl solution at pH 6.1,” Mater. Chem. Phys., 91, 325–329 (2005).

M. Jafari, M. H. Enayati, M. H. Abbasi, and F. Karimzadeh, “Thermal stability and structural changes during heat treatment of nanostructured Al2024 alloy,” J. Alloys Comp., 478, 260–264 (2009).

S. M. R. Mousavi Abarghouie and S. M. Seyed Reihani, “Aging behavior of a 2024 Al alloy-SiCp composite,” Mater. Des., 31, No. 5, 2368–2374 (2010).

Z. Liu, P. H. Chong, A. N. Butt, et al., “Corrosion mechanism of laser-melted AA2014 and AA2024 alloys,” Appl. Surf. Sci., 247, 294–299 (2005).

M. Iannuzzi and G. S. Frankel, “Inhibition of aluminum alloy 2024 corrosion by vanadates: an in situ atomic force microscopy scratching investigation,” Corrosion, 63, 672–688 (2007).

R. G. Buchheit, R. P. Grant, P. F. Hlava, et al., “Local dissolution phenomena associated with S phase (Al2CuMg) particles in aluminum alloy 2024-T3,” J. Electrochem. Soc., 144, No. 8, 2621–2628 (1997).

Z. Huda, N. I. Taib, and T. Zaharine, “Characterization of 2024-T3: an aerospace aluminum alloy,” Mater. Chem. Phys., 113, 515–517 (2009).

Acknowledgements

Mr. Rana M. Ayub and Mr. Sajjad Ahmad are acknowledged for their help during the experimental work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Problemy Prochnosti, No. 6, pp. 69 – 81, November – December, 2013.

Rights and permissions

About this article

Cite this article

Afzal, N., Shah, T. & Ahmad, R. Microstructural Features and Mechanical Properties of Artificially Aged AA2024. Strength Mater 45, 684–692 (2013). https://doi.org/10.1007/s11223-013-9504-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11223-013-9504-8