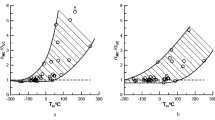

The surveillance fracture toughness test data for WWER-1000 reactor pressure vessel materials from Ukrainian nuclear power plants were re-evaluated using the Master curve methodology. It has been shown that experimental temperature dependence of fracture toughness parameters and a scatter of KJc values are in a good agreement with a Master curve shape and 5 and 95% tolerance bounds for materials in unirradiated condition and after neutron irradiation up to fluence 41. 2·1022 n/m2 (E > 0.5 MeV). For the Khmelnitsky nuclear power plant unit 1 reactor pressure vessel an analysis has shown that normative approach PNAÉ G-7-002-86 underestimates essentially the measured fracture toughness of unirradiated weld metal. The reference temperature T0 calculated according to the Master curve method was compared with a critical brittleness temperature TK0 for reactor pressure vessel materials in unirradiated condition. It has been found that temperature T0 is much lower than TK0 . Furthermore a difference between T0 and TK0 values varies essentially from one material to another. A correlation between temperatures T28 J defined from Charpy energy curve and T0 values calculated from precracked Charpy specimens test was obtained. The analysis has shown that the results based on precracked Charpy specimens can provide nonconservative assessment of fracture toughness for WWER-1000 reactor pressure vessel materials.

Similar content being viewed by others

References

PNAÉ G-7-002-86. Strength Calculation Norm for Nuclear Power Plant Equipment and Piping [in Russian], Énergoatomizdat, Moscow (1989).

K. Wallin, “Statistical re-evaluation of the ASME K Ic and K IR fracture toughness reference curves,” Nucl. Eng. Design, 193, 317–326 (1999).

M. Kirk and M. Mitchell, “Potential roles for the Master curve in regulatory application,” Int. J. Press. Vess. Piping, 78, 111–123 (2001).

ASTM E 1921-97. Standard Test Method for Determination of Reference Temperature, T0 , for Ferritic Steels in the Transition Range, ASTM (1997).

K. Wallin, “Validity of small specimen fracture toughness estimates neglecting corrections of constraint,” in: Constraint Effects in Fracture Theory and Applications, ASTM STP 1244, Philadelphia (1995), pp. 519– 537.

E. Grynik, V. Gukalova, L. Chyrko, et al., “Results from surveillance program and their analysis,” in: Proc. of the IAEA Specialists Meeting Irradiation Embrittlement and Mitigation (IWG-LMNPP-01/2, May 14–17, 2002, Gloucester, UK), Vienna (2002), pp. 277–284.

K. Wallin, “A simple theoretical Charpy-V – KIc correlation for irradiation embrittlement,” in: Innovative Approaches to Irradiation Damage and Fracture Analysis, PVP (1989), Vol. 170, pp. 93–100.

C. Ruggieri, R. H. Dodds, and K. Wallin, “Constraint effects on reference temperature, T0 , for ferritic steels in the transition region,” Eng. Fract. Mech., 60, 19–36 (1998).

Author information

Authors and Affiliations

Additional information

Translated from Problemy Prochnosti, No. 6, pp. 105 – 112, November – December, 2010.

Rights and permissions

About this article

Cite this article

Revka, V.M., Grynik, E.U. & Chyrko, L.I. The use of master curve method for statistical re-evaluation of surveillance test data for WWER-1000 reactor pressure vessels. Strength Mater 42, 705–710 (2010). https://doi.org/10.1007/s11223-010-9257-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11223-010-9257-6