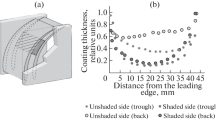

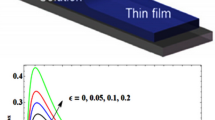

Cathodic arc deposition of coatings onto the surface of products with a complex geometry (coupled turbine blades, integrally bladed disks) can be complicated by the problem of the coating thickness tolerance. This paper suggests experimental dependences between nonuniformity of the coating thickness synthesized by cathodic arc deposition and geometrical parameters of the blade channel, namely its length, width, and curvature radius.

Similar content being viewed by others

References

A. M. Lakhin, Progresivni tekhnologiї i sistemi mashinobuduvannya, No. 3-4, 101–107 (2014).

M. Abdoos, K. Yamamoto, B. Bose, G. Fox-Rabinovich, and S. Veldhuis, Wear, 422, 128–136 (2019).

T. M. Rodgers, H. Zhao, H. N. G. Wadley, J. Vac. Sci. Technol. A, 33, No. 6, 061509 (2015).

A. Anders, Cathodic Arcs: From Fractal Spots to Energetic Condensation. New York: Springer Inc., 2008.

E. Vardanyan, A. Nazarov, R. Nagimov, K. Ramazanov and A. Maslov, in: Proc. 7th Int. Congr. on Energy Fluxes and Radiation Effects, Tomsk, Russia, 2020, pp. 853-855; DOI: https://doi.org/10.1109/EFRE47760.2020.9242024.

H. Chung, et al., Energy, 118, 1275–1285 (2017).

L. Griffiths, No Limits: Manufacturing the Most Complex Parts with VELO3D, in: 3D Printing & Additive Manufacturing Intelligence; www.tctmagazine.com/additive-manufacturing-3d-printing-news/no-limitsmanufacturing-most-complex-parts-velo3d (accessed December 10, 2022).

I. I. Yagafarov, “Technological support of surface layer quality and accuracy of precision machinery during cathodic arc deposition of coating”, Candidate’s Dissertation in Engineering Sciences [in Russian], Ufa University of Science and Technology, Ufa (2014).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Oleinik, A.V., Nazarov, A.Y. & Ramazanov, K.N. Influence of Curvature Radius and Blade Channel Parameters on Coating Thickness. Russ Phys J 67, 17–23 (2024). https://doi.org/10.1007/s11182-024-03083-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11182-024-03083-7